-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Researchers at the University of Colorado in the United States have developed a new 3D printing method that can make carbon fiber reinforced composite parts without supporting structur.

The technology relies on a specially developed thermoset resin and a unique curing process called front-side polymerization, which enables the material to cure as it is extruded during printi.

Frontal polymerization 3D printing method that can generate free-form and support structures

Frontal polymerization 3D printing method that can generate free-form and support structuresThis is good news for those who need to use 3D printed composite par.

While composite filaments are the most readily available and easiest to use, the resulting parts suffer from drawbacks when applied to high performance structures due to low service temperatures, poor interlayer mechanical properties, high porosity and relatively low fiber volu.

The R&D team said they found a solution in fiber-filled thermoset composite resi.

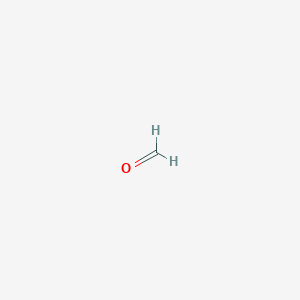

In this study, the team developed a DCPD (dicyclopentadiene)-based thermoset resin filled with short carbon fibers that begins to cure under localized heat conditio.

Self-sustaining exothermic reaction that propagates up the printed part, curing the material with heat along the way

Self-sustaining exothermic reaction that propagates up the printed part, curing the material with heat along the wayTo put it another way, by precisely matching the printing speed to the front-end speed (the propagation speed of the exothermic reaction), a completely unsupported free-form structure can be achieved and cured immediate.