-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Lithography is the use of optical, chemical and physical methods to transfer the designed circuit diagram to the surface of the wafer and other surfaces, which is the core link

Market size

Photoresist is mainly used in semiconductors, display panels and PCBs, of which display panels account for 27%, PCBs and semiconductors account for 25% and 24%

The global photoresist market grew from US$5.

According to incomplete statistics, at present, Jingrui Electric Materials and other domestic listed companies that have achieved mass production of photoresist, the total revenue of photoresist-related business in 2021 will reach 2.

Photoresist is a technology and capital-intensive industry, the global supply market is highly concentrated, Japan's JSR and other five leading enterprises occupy 87% of the global photoresist market share, while overseas leaders have also achieved EUV and other high-end process mass production

Domestic photoresist high-end field gradually breakthrough

China's photoresist industry started late, the production capacity is mainly concentrated in PCB photoresist, TN/STN-LCD photoresist and other low-end products, of which PCB photoresist accounted for 94%, while TFT-LCD, semiconductor photoresist and other high-end products still need a large number of imports

In recent years, the Chinese government has vigorously supported the development of the semiconductor and raw material industry, and has successively introduced a number of policies to support the development of the photoresist industry, promote the vigorous research and development of the industry, break through the "card neck" technology, and realize the localization of the core technology of

In terms of advanced semiconductor photoresist, the domestic self-sufficiency rate of g-wire and i-line photoresist suitable for 6-inch silicon wafers is about 10%, the domestic self-sufficiency rate of KrF photoresist suitable for 8-inch silicon wafers is less than 5%, and the Domestic ArF photoresist suitable for 12-inch silicon wafers basically relies on imports, and EUV photoresist is still in the research and development stage

With the transfer of the electronic information industry to China and the improvement of the supporting demand of the semiconductor industry chain, it is the general trend

In terms of EUV glue, Beijing Kehua has passed the 02 special acceptance

At the same time, the new domestic photoresist projects continue to be

set up.

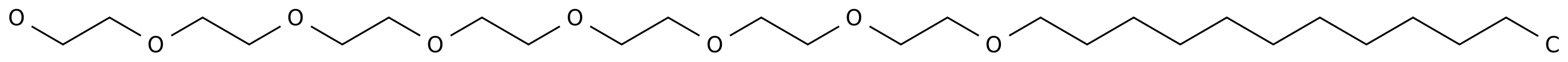

The raw materials for the production of photoresist mainly include photoresist resins, photoinitiators, solvents, monomers and other additives, of which resins and photoinitiators are the most critical components

.

With the development of lithography technology, the components of the photoresist corresponding to each exposure wavelength also change

with the development of lithography technology.

For a long time, photoresist-specific electronic chemicals have been mainly monopolized

by professional companies in Japan, Europe and the United States.

In terms of photoresist resins, Japanese and American companies currently occupy major markets

.

In china, Shengquan, Tongcheng New Material, Qiangli New Material, etc.

are currently beginning to be gradually laid out

.

In terms of photoinitiators, the current market is mainly occupied by enterprises in Japan, South Korea, Germany and other countries, and the current domestic strong new materials and Jiuri new materials have the ability to

induce dose production of photoresist.

In terms of monomers, Microchip New Material, Xuzhou Bokang, Wanrun Shares, and Related New Material have mass production capabilities

.

In terms of solvents, the technical barriers to the preparation of photoresist solvents are relatively low, and the commonly used material is propylene glycol methyl ether acetate (PGMEA or PMA), and domestic enterprises are involved in more

.

At present, there are 5 major manufacturers in China, namely Jiangsu Hualun, Jiangsu Tianyin Chemical, Baichuan Shares, Yida Shares, and Jiangsu Sanmu

.

At present, although in the overall R & D and production capacity, domestic companies can not fully compete with international competitors such as BASF, but after years of technical accumulation, the country has formed a certain production capacity of photoresist electronic chemicals, the market share of related companies has gradually increased, and import substitution is continuing

.