-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

[ Star Enterprise of Chemical Machinery Equipment Network ] BASF (Ludwigshafen, Germany), Quantafuel ASA (Oslo, Norway) and Remondis SE & Co.

KG (Lunen, Germany) signed a memorandum of understanding (MoU) to jointly evaluate Cooperation in chemical recycling includes joint investment in a plastic waste pyrolysis plant.

Chemical machinery and equipment network star enterprise chemical machinery and equipmentKG (Lunen, Germany) signed a memorandum of understanding (MoU) to jointly evaluate Cooperation in chemical recycling includes joint investment in a plastic waste pyrolysis plant.

Remondis, one of the world's leading waste and water management companies, intends to provide suitable plastic waste to the plant.

BASF uses the generated pyrolysis oil as a raw material in the integrated production base as part of its chemical recycling project.

Quantafuel intends to provide technology and operate the plant.

The company is an expert in the pyrolysis of mixed plastic waste and the purification of the pyrolysis oil produced; the technology is jointly developed and held with BASF.

The location of the pyrolysis plant will be evaluated together.

BASF uses the generated pyrolysis oil as a raw material in the integrated production base as part of its chemical recycling project.

Quantafuel intends to provide technology and operate the plant.

The company is an expert in the pyrolysis of mixed plastic waste and the purification of the pyrolysis oil produced; the technology is jointly developed and held with BASF.

The location of the pyrolysis plant will be evaluated together.

Every year, nearly 20 million tons of plastic waste in Europe cannot be recycled.

By establishing chemical recycling as a supplementary solution to mechanical recycling, it is possible to bring more plastic waste back into the material cycle, otherwise the waste will be incinerated.

Pyrolysis technology can be used to treat plastic waste streams that have not been mechanically recycled due to technical or economic reasons.

By establishing chemical recycling as a supplementary solution to mechanical recycling, it is possible to bring more plastic waste back into the material cycle, otherwise the waste will be incinerated.

Pyrolysis technology can be used to treat plastic waste streams that have not been mechanically recycled due to technical or economic reasons.

In order to maximize the realization of the circular economy of plastics, the two parties will determine which waste plastics provided by Remondis can be chemically recycled in the future.

Lars Kissau, Senior Vice President of Global Strategic Business Development of BASF’s Petrochemical Division, said: "BASF has set a goal for itself to process 250,000 tons of recycled raw materials per year from 2025.

In this regard, it is important to use plastic waste The extracted raw materials would otherwise not be recycled.

Cooperating with companies in the waste management and recycling sector and innovative technology suppliers is an ideal combination to establish a sustainable circular economy model for previously unrecycled plastic waste.

However, only in Under a favorable regulatory environment, it is possible to solve the challenge of plastic waste.

"

In this regard, it is important to use plastic waste The extracted raw materials would otherwise not be recycled.

Cooperating with companies in the waste management and recycling sector and innovative technology suppliers is an ideal combination to establish a sustainable circular economy model for previously unrecycled plastic waste.

However, only in Under a favorable regulatory environment, it is possible to solve the challenge of plastic waste.

"

Kjetil Bøhn, CEO of Quantafuel, said: "Remondis and BASF are excellent partners to realize such an ambitious project in Central Europe within a tight time frame and operate successfully in the long term.

We are steadily advancing our initial business in Skiff.

The upgrade of the factory is working, and I am very happy to start implementing the promotion of this technology now.

"

We are steadily advancing our initial business in Skiff.

The upgrade of the factory is working, and I am very happy to start implementing the promotion of this technology now.

"

Jürgen Ephan, General Manager of Remondis Recycling Company, pointed out the importance of the joint project: "In order to achieve the sustainable development goals set by the European Union in its visionary "Green Agreement", increase Recycling quotas are critical.

We believe that chemical recycling can provide a meaningful contribution.

Therefore, we are happy to work hand in hand with BASF and Quantafuel on the road to higher recycling rates.

"

We believe that chemical recycling can provide a meaningful contribution.

Therefore, we are happy to work hand in hand with BASF and Quantafuel on the road to higher recycling rates.

"

Legislation at the EU and national levels will create a framework for chemical recycling, thereby shaping its ability to contribute to the greater circular economy of plastics.

This includes acknowledging that products based on chemically recycled raw materials are counted towards the goal of achieving recycled content.

This includes acknowledging that products based on chemically recycled raw materials are counted towards the goal of achieving recycled content.

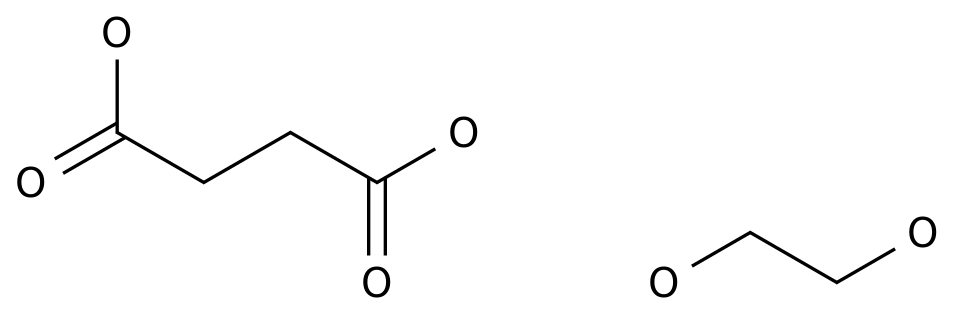

Pyrolysis oil extracted from plastic waste is imported into BASF's integrated production base, thereby saving the same amount of fossil resources.

Because pyrolysis oil is directly inserted into the starting point of the chemical value chain, the final product sold has exactly the same characteristics as the product produced from fossil raw materials.

The share of recycled materials is allocated to the final product according to a third-party certified mass balance method, which enables BASF to provide its customers with certified products bearing the Cycled name.

Because pyrolysis oil is directly inserted into the starting point of the chemical value chain, the final product sold has exactly the same characteristics as the product produced from fossil raw materials.

The share of recycled materials is allocated to the final product according to a third-party certified mass balance method, which enables BASF to provide its customers with certified products bearing the Cycled name.

Plastic chemistry recycling is coming fiercely! We sincerely invite you to participate in the first plastic chemical recycling technology market policy forum from 9:00-13:00 on April 30.

We will invite chemical recycling companies, parks, polymer companies, brand companies, and experts and companies in the chemical recycling industry chain.

Let's discuss chemical recycling together and have a collision of ideas.

We will invite chemical recycling companies, parks, polymer companies, brand companies, and experts and companies in the chemical recycling industry chain.

Let's discuss chemical recycling together and have a collision of ideas.

Original title: BASF, Quantafuel and Remondis will cooperate in the chemical recycling of plastic waste