-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction The 22nd Session of the Standing Committee of the 13th National People's Congress on October 17, 2020 adopted the Biosecurity Law of the People's Republic of China, Chapter VIII of the Regulations states: "To strengthen biosecurity capacity-building and improve the ability and level of response to biosusable events", the regulations emphasize that people's governments at or above the county level should support biosecurity. The development of the cause, according to the division of powers, will support the development of the following biosecurity related expenditures included in the government budget, including the construction and operation of key infrastructure, research and development of key technologies and products based on biosecurity law, the following will be from the biopharmaceutical supply chain security aspects of the domestic alternatives to the relevant products risk analysis, and give recommendations for solutions.

With the development of China's economy, changes in living environment, changes in people's health concepts and the acceleration of the aging process of the population and other factors, the biopharmaceutical industry closely related to the quality of human life has maintained a sustained growth trend in recent years, the industry has become one of the fastest growing industries in the world.

China is the world's largest emerging market in the pharmaceutical industry, with the total output value of China's pharmaceutical industry increasing from 104.8 billion yuan in 2009 to 434.83 billion yuan in 2019, with a compound annual growth rate of 18.2%.

recent years, China's biopharmaceutical industry has made rapid development, some sub-sectors of high-end industries are gradually keeping up with the development of foreign technology, the pace of domestic substitution accelerated.

But we also still see that most of the high-end products of the core technology and key raw materials are still monopolized abroad, the outbreak has exacerbated the process of counter-globalization, biopharmaceutical supply chain resource elements of the high degree of foreign dependence, not only will lead to increased risks in the biopharmaceutical industry chain, but also restrict the healthy development of China's biopharmaceutical industry.

1. Analysis of the current situation of China's biopharmaceutical supply chain Biopharmaceuticals according to products can be divided into 3 categories, respectively, biological medicine, traditional Chinese medicine and small molecular drugs, biopharmaceuticals can be subdivided into genetically engineered drugs, antibody engineering drugs, blood products drugs, vaccines, protein drugs, product research and development and production process raw materials, instruments, equipment, there are differences, but also a certain similarity.

Figure 1 Biopharmaceutical Classification Photo Source: Firestone Creation Figure 2 Biopharmaceutical Research and Development Production Chain Link Image Source: Firestone Creates 1. The status quo of China's biopharmaceutical supply chain (1) Raw materials: most of the domesticated, a small number of threshold products fully domesticated still take time.

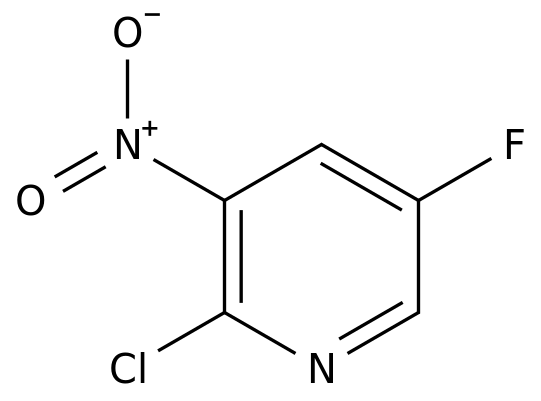

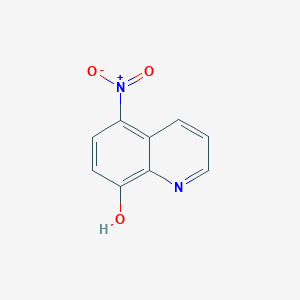

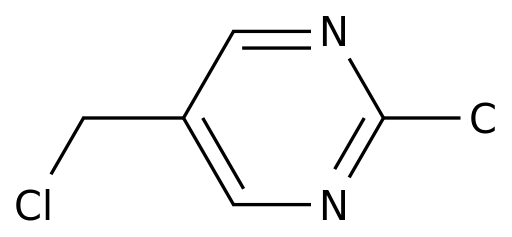

(1) small molecular drugs dedicated raw materials: China is the world's largest exporter of raw materials, intermediates, relying on China's complete industrial system, small molecular drugs raw materials can basically be domestic supply.

, intermediates due to high pollution in the production process, due to environmental reasons, the industrial chain transferred to India, become a constraint.

(2) Biopharmaceuses special raw materials: biopharmaceuses rely on biotechnology, China in the field of biotechnology and Europe and the United States and other developed countries still have a big gap, due to the high technical threshold, domestic and foreign regulatory threshold differences and raw material source control (e.g., high levels of domestic bovine serum antibiotics affect cell culture effect, New Zealand cattle serum is monopolized by foreign giant sources), many raw materials of biological drugs are dependent on imports, such as special media for biological drugs, animal cell culture, high-end fermented bacteria, enzymes, primary cells, specific proteins, monoantigens, fluorescent dyes and so on.

These products are largely monopolized in several large biological companies abroad, such as Thermofisher, Merck-Sigma, Roche Diagnostics, GE, Corning and Qiagen, and the imported products have clear advantages in terms of technical content and quality stability.

some low-tech raw materials can be domesticated, such as basic culture, common fermented bacteria, common enzyme preparations, ordinary cells, common proteins and antibodies, fluorescent dyes and so on.

(3) general raw materials: chemical reagents, solvents: basically domestic replacement, such as Xiyi Chemical, National Medicine, Tiantian and so on.

small difference between the domestic quality of a small number of color spectrum pure reagents and imported brands Merck, HONEYWELL and Fisher.

: Most of them have been domesticated, such as Anhui Mountain River, Huzhou Outlook and so on.

part of the functional or high-quality requirements of accessories, such as EVONIK acrylic resin, Shin-Etsu hydroxypropyl cellulose, JRS microcrystalline cellulose, Ashland polyvitazone or sterile preparations with low endotoxin accessories, there is a large quality gap or technical bottlenecks, mainly rely on imports, in the short term it is difficult to fully achieve domestic replacement.

: PVDC, composite film, aluminum foil, plastic bottles, aluminum plastic caps, Xilin bottles, halogenated butyl plugs, pre-charged needles, card bottles, etc. have been basically domesticated.

However, it should be noted that most of the raw materials produced by domestic high-quality pharmaceutical packaging materials rely on imports, such as polystyrene-butane copolymer PSB and high density polyethylene HDPE for high-quality pharmaceutical packaging materials for oral preparations. Production of halogenated butyl rubber raw materials (long-term by the German Lanxess, the United States Exxon Mobile and other foreign manufacturers monopoly), 5.0 neutral boron silicon glass pipe (long-term by the German SCHOTT, the United States Corning, Japan Nipro, Japan NEG, Italy Neubor Glass monopoly).

addition, due to the domestic YBB standard for the quality of pharmaceutical packaging materials requirements are lower than the United States USP-lt;661;, USP-lt;88;, USP-lt;381-gt; and the European Union 2023/2023/1 2006/EC, 10/2011/EC, EP 3.2.9 and other regulations, domestic halogenated butyl plug quality is generally lower than the import of the three major brands: West, Datwyler, Stelmi, and even some of the risk of genetic toxic impurities exceeding the standard.

With the sustained and rapid development of China's biomedicine, especially high-end biopharmaceuticals and innovative drugs, will put forward higher requirements for the quality and design of pharmaceutical packages in China, for example, silicone oil in syringes make protein drugs insoluble particles affect drug quality, domestic card pen can not achieve precise quantitative administration, the existing domestic drug packages will not be able to fully meet the development needs of high-end biologics, innovative drugs.

with China's demand volume, foreign domestic package materials due to long-term or limited capacity and other factors, will not be able to fully meet China's demand.

such as China's drug packaging to continue to maintain the current low-level development status quo, will become a bottleneck restricting the healthy development of China's high-end biomedicine.

: has been basically domesticated, in addition to some special paper imported from abroad, such as Finland UPM special label paper.

(2) Testing instruments: the gap is large, from the overall localization, there is still a long way to go, with high-quality chemical materials, components, sensing technology, self-control systems and other domestic industrial chain or flow research technology and other basic disciplines are closely related to the development.

through the statistics of the General Administration of Customs, it can be seen that the trade deficit between the import and export of scientific instruments is obvious, the domestic market for scientific instruments is still heavily dependent on imported products, the largest proportion of imports of experimental analytical instruments, the highest degree of dependence.

In addition, with the rapid development of domestic biomedicine, the demand for optical instruments such as microscopes is increasing rapidly, although the market share of domestic Xiamen Motic, Shanghai Caikang, Yongxin Optics, Yuyu Optics has increased, but compared with Germany ZEISS, Germany Leica, Japan Olympus, Japan's Nikon four optical giants, we still have a long way to go.

on the other hand, the amount of instrument exports is increasing and the amount of instrument imports is decreasing, indicating that the trend of domestic alternatives is increasing.

table 1 January-November 2019 Customs scientific instrument import and export amount statistics (US$100 million) Data source: General Administration of Customs Note: experimental analysis categories include chromatography in customs statistics, electronic balance, mass spectrometer, mass spectrometry instrument, electrophoresis instrument, spectrophotometer, etc.

test machine category includes electronic all-in-one test machine, hardness meter, test bench, ultrasonic detection detector, magnetic powder detector, vortex detection detector and other materials test machine and equipment parts, accessories.

optical instruments are mainly stereo microscopes, duplex optical microscopes, electron microscopes and parts.

Table 2 Q3 2019 Q3 inspection and testing service industry main equipment import and export quantity and value data source: The General Administration of Customs according to the general administration of scientific instruments and customs import and export data, the application effect of domestic biopharmaceutical enterprises and domestic alternative degree, the current situation of the testing instrument market can be divided into three kinds: basically achieved localization, domestic import quality function gap, foreign monopoly card neck.

Table 3: The current situation of the testing instrument market Source: Firestone creates root according to the public data overall, China in the biomedical testing equipment, there is still a very long way to go.

As far as product technology is concerned, static testing and precision and reproducible requirements are not high instruments, the overall technology and import gap is not large, the gap is mainly manifested in two aspects: raw material quality and core components differences, some domestic enterprises fear high cost can not get high returns, the use of low-end components, affecting product performance;

these two factors, has become a bottleneck restricting the further upgrading of domestic static instrument technology.

and dynamic products, in addition to domestic hydraulic valves, pumps, sensors, controllers, optical imaging systems and other key components of domestic "there is no" and domestic accuracy, indicators do not meet international standards "can not be used", the lack of functional software technology, but also restrict the development of dynamic instrument multi-dynamic instrument control system, resulting in domestic dynamic instrument measurement accuracy, stability and imported instruments there is a large gap.

(3) pharmaceutical process equipment: the technology gap is narrowing, the domestic replacement rate is increasing.

the same drug preparation can affect the safety, efficacy and stability of the drug preparation due to the different process equipment conditions selected.

pharmaceutical process equipment is an important means of production, but also can not ignore one of the pollution factors.

the specifications, structure, materials and performance of pharmaceutical equipment have a great impact on drug production, and there is a close correlation with GMP in drug production.

Therefore, in addition to the use of functional properties, pharmaceutical process equipment should also have in the designated use of the scene, the completion of the basic process of mechanical and electrical movement functions and operation of the drug and studio area is not contaminated with the main GMP-related functions: purification function, cleaning function, online monitoring and control function, safety protection function.

Because domestic companies lack the research power of biological process technology and the integrated research system of process, engineering and equipment, domestic bioreactive devices can not be synchronized with the development of biotechnology to achieve the development capacity of bioreactive devices in line with GMP requirements, in addition, for the highly automated laboratory devices of deep integration of biotechnology lack trial capacity, domestic bioreactive devices mainly in simple external imitation, the domestic bioreactive device market is mainly dominated by the United States ABEC, the United States Cytiva, Germany Sartorius monopoly.

addition to bioreactive devices, China's domestic pharmaceutical process equipment can basically meet the functional requirements of use, but in terms of production quality and productivity, there are still some gaps with foreign imported brands.

main features are: (1) the safety of material selection, (2) functional design, structural design, equipment design, equipment interface design non-polluting, (3) equipment running speed.

gap between domestic and foreign process equipment exists, but we also want to see a positive side.

The leading enterprises in china, represented by Chutian and Dongfulong, are gradually narrowing the gap and even some of them have entered the international competition arena through continuous research and development investment, foreign acquisitions (Chutian's acquisition of Romoco, Germany), joint ventures and other initiatives.

. Second, biopharmaceutical supply chain security recommends the development of biopharmaceuticals in China into a fast track, biopharmaceutical industry as one of the strategic emerging industries that China attaches great importance to, biopharmaceutical supply chain security has become an important factor in the benign development of this strategic emerging industry.

with the focus of China's biopharmaceutical industry and the uncertainty of the external international environment, on the one hand, the localization of biopharmaceutical supply chain will become an urgent development need.

China should continue to build a scientific service system for research and development through strengthening basic research input, industry chain support and personnel training, drive change through innovation, gradually promote the modernization of the biopharmaceutical industry chain, and help biopharmaceutical innovation and transformation.

on the other hand, upstream key raw materials have become an important link restricting the development of the industry, providing a safe and controllable supply chain security system of high quality and price stability has also become an important task to be solved urgently, through the construction of biomedical innovation service complex, the introduction of high-quality supplier resources, the formation of from the laboratory, pilot, clinical, production to marketing support, so that innovative enterprises in industrial clusters, with the shortest radius to obtain innovative resources and services, so as to ensure the safety, stability and efficiency of the supply chain.

author | golden fairy flower