From the perspective of the pharmaceutical equipment industry, look at the highlights of the newly revised Measures for the Supervision and Administration of Drug Production

-

Last Update: 2020-07-16

-

Source: Internet

-

Author: User

Search more information of high quality chemicals, good prices and reliable suppliers, visit

www.echemi.com

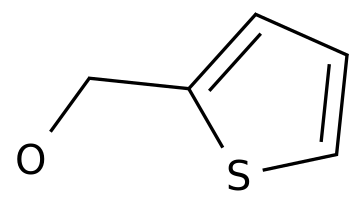

On July 1, 2020, the State Administration of Market Supervision and Administration issued a new revision of the Measures for the Supervision and Administration of Drug Production (hereinafter referred to as the New Measures) officially implementedthis revision fully reflects the new requirements for drug production supervision and management in the new revised Drug Administration Law, defines the scope of drug production license, the scope of drug GMP compliance inspection, strict drug market licensing holders, production enterprises entrust production management;from the point of view of the pharmaceutical equipment industry, the new Measures pay more and more attention to the impact of production equipment on the quality of drugs, specifically from the following points to reflectpharmaceutical equipment (source: pharmaceutical network) the new Measures mention: "Enterprises should develop production processes and quality standards for the pharmaceutical products to be produced, complete the plant, facilities and equipment related to the identification and verification."it is understood that equipment verification and confirmation of equipment can ensure more stable pharmaceutical production, there are many documents related to the verification of pharmaceutical equipment, the basic use of drug production verification guidelines, GMP regulations requirements for basic inspection, but also in accordance with the customer's URS for special verification designThe method sands and basis for all inspections ofitems are supported by documentationThe purpose ofequipment verification includes: checking and confirming the material used in the equipment, design, manufacture, in line with GMP requirements, checking the equipment's documentation complete and in line with GMP requirements, checking and confirming that the installation of the equipment meets the production requirements, the utility engineering system complete and in line with the design requirements, and confirming that the control function of the equipment meets the design requirementsin terms of equipment confirmation, the industry said that the equipment in the cycle of management and equipment confirmation is the key to ensure that product production meets the needs, in the dynamic management process of equipment, to ensure its quality requirements, the implementation of equipment confirmation and re-confirmation, so as to ensure the effective operation of pharmaceutical equipmentit is understood that, in general, equipment confirmation includes design confirmation, installation confirmation, operational confirmation, and performance confirmationto the performance confirmation of the reactor as an example, the enterprise use of reactor is to achieve heating, cooling, insulation and other requirements, then performance confirmation should carefully examine whether these requirements can be achievedAt the same time,the new Measures require that, "before the drug is approved for listing, the drug market license holder, the new business enterprise, and the new construction, alteration, expansion of the workshop or production line in the original or off-site, after obtaining the "drug production license" or "drug production license" increases the scope of production, shall apply for the drug GMP compliance check."the workshop or production line involved in the production of the drug listed by the holder of the drug, the entrusted production enterprise shall apply for the drug GMP compliance check before July 1, 2020, if the Drug Production License has been obtained in accordance with the law, and its workshop or production line has not passed the drug GMP compliance check, it shall apply for the drug GMP compliance check the products of the drug after the listing license holders, production enterprises should continue to comply with the quality management norms of pharmaceutical production ", which also means that if pharmaceutical companies need to build, renovate, expand workshops or production lines, they will need to go through a drug GMP compliance check in the process of new construction, alteration, expansion of workshop or production line, workshop construction and transformation, the introduction of new equipment, etc need to meet gmp requirements industry said that in recent years, with the tightening of drug quality supervision, pharmaceutical companies in the process of implementing GMP requirements, the requirements of hardware and software are also improving, which brings opportunities and challenges to pharmaceutical equipment companies equipment needs both hardware and software to help pharmaceutical companies improve production efficiency, ensure product quality, and reduce the cost of labor at present, the renewal cycle of pharmaceutical equipment is constantly shortening, the industry began to move towards automation, intelligent direction , the new Measures clearly state that "if the conditions such as equipment for key production facilities and equipment of a pharmaceutical manufacturing enterprise change, the enterprise shall conduct research in accordance with the newly revised Measures for the Administration of Drug Registration and the requirements for the management of the change, and shall make supplementary applications, filings or reports in accordance with the provisions after completing the relevant change sourcing." why should companies take the initiative to make supplementary applications, filings or reports under such circumstances? In the industry's view, the quality of the product is not only related to the process, and the key equipment also has a lot to do with , therefore, timely record of changes in critical equipment is conducive to preventing the change of key equipment on the quality of products unknowable, but also conducive to future production process changes

This article is an English version of an article which is originally in the Chinese language on echemi.com and is provided for information purposes only.

This website makes no representation or warranty of any kind, either expressed or implied, as to the accuracy, completeness ownership or reliability of

the article or any translations thereof. If you have any concerns or complaints relating to the article, please send an email, providing a detailed

description of the concern or complaint, to

service@echemi.com. A staff member will contact you within 5 working days. Once verified, infringing content

will be removed immediately.