-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Keywords: non-isocyanate polyurethane cyclocarbonate epoxy hybrid coating

Background: Polyurethane is a key material widely used in chemical, automobile manufacturing, electronic instruments, aerospace, military, medical equipment and other fields.

Traditional polyurethane is synthesized from diisocyanate or triisocyanate and polyol through the polymerization of isocyanate groups and hydroxyl groups.

In order to reduce the harm caused by the production of isocyanate and the application of isocyanate-based polyurethane, the cyclocarbonate/amine reaction method has been developed to synthesize polyurethane.

Because polyurethane is not synthesized from isocyanates using this method, this type of product is called non-isocyanate polyurethane (NIPU).

(1) Most of the raw materials used in NIPU, such as cyclocarbonates and amines, are safer than isocyanates, reducing the processing costs due to safety considerations;

(2) Polyurethane synthesized by cyclic carbonate/amine reaction contains amino groups on the main chain and primary or secondary hydroxyl groups on the side chains.

These hydroxyl groups can facilitate the later modification of the material.

(3) In addition, the amine compounds in this method are commonly used in synthesis reactions, and there are many types to choose from.

Cyclic carbonates can also be easily synthesized in a variety of ways.

Although the research of NIPU has been extensively developed in recent years, the synthesis of NIPU still faces the main problem of low cyclocarbonate/amine reactivity.

Therefore, this means that the curing of NIPU on the substrate takes a long time.

research content

1.

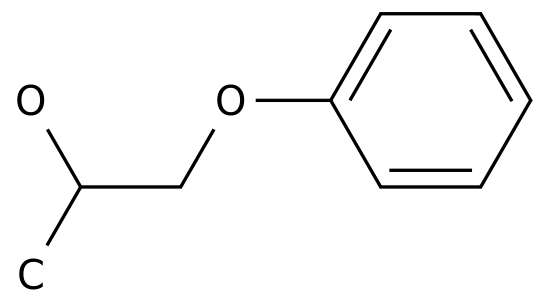

Synthesis of DGDC

DGDC is prepared from diglycerin and excess dimethyl carbonate (DMC) under the catalysis of sodium methoxide, as shown in Scheme 1.

The reaction was carried out in a 500 ml reaction flask equipped with a mechanical stirrer, dropping funnel, Dean-Stark device and nitrogen inlet.

First, diglycerin (83.

2.

Synthesis of water-based amino-terminated NIPU

Through the three steps of prepolymer synthesis, neutralization and dispersion, the amino-terminated water-based NIPU was synthesized; the synthesis route is shown in Scheme 1.

Table 1 lists the synthesis details of the amino-terminated NIPU prepolymer.

3.

Synthesis of water-based epoxy chain extender

Using similar technology and equipment, using diethanolamine and trimethylolpropane triglycidyl ether (TTE) as raw materials, the molar ratio of the two is 1:1, and the synthesis of water-based epoxy chain extender is shown in Route 2.

.

Dissolve TTE (30.

1 g, 0.

1 mol) in 20.

0 mL of acetone to obtain a TTE solution.

Mix diethanolamine (10.

4 g, 0.

1 mol) and methanol (20.

0 mL) to make a diethanolamine solution.

The diethanolamine solution was added dropwise to the flask containing the TTE solution at room temperature and stirred for 24 h.

Then, neutralize the tertiary amine in diethanolamine with sufficient acetic acid and react for 1 h.

After that, a certain amount of deionized water was slowly added to the epoxy chain extender and dispersed at high speed (1500 rpm) for 3 h.

Finally, a rotary evaporator was used to remove the remaining methanol to obtain a water-based epoxy chain extender with a solid content of about 20 wt%.

4.

Preparation of waterborne NIPU epoxy hybrid coating

According to the formula in Table 2, the water-based ammonia-terminated NIPU and the water-based epoxy chain extender were mixed to prepare the water-based NIPU epoxy hybrid coating.

First, mix the water-based ammonia-terminated NIPU and water-based epoxy chain extender into a glass bottle, stir vigorously for about 5 minutes under magnetic stirring, and let it stand for 10 minutes to remove air bubbles.

When all the bubbles disappeared, a water-based NIPU epoxy hybrid coating was applied to the glass surface with a wet film thickness of 120 μm.

In order to obtain a better film-forming effect, the film was baked in an oven at 100°C for 2 h, and finally the sample was placed in air at room temperature for 7 days to obtain a solid film with a dry film thickness of about 30 μm.

Results discussion

1.

DGDC nuclear magnetic hydrogen spectrum and carbon spectrum

2.

The formation of amino-terminated NIPU prepolymer

3.

Hydrogen NMR spectrum of water-based epoxy chain extender

4.

Determine Tg by DSC method

5.

Thermal stability

6.

Conventional layer performance

in conclusion:

In this study, three environmentally-friendly water-based NIPU epoxy hybrid coatings were synthesized using renewable cyclocarbonate, FDA, IDM and water-based epoxy chain extenders as raw materials, and their thermal and mechanical properties were studied.

Among them, the water-based NIPU epoxy hybrid coating film with 50% wt% FDA content exhibits a double tg phenomenon similar to that of traditional isocyanate-based polyurethane.

This is due to the use of a large number of FDA as the soft segment, which leads to phase separation in the system.

In addition, with the increase in the amount of FDA in the soft segment, due to the decrease in the number of carbamate groups that are easily broken during the thermal degradation process, the thermal stability has also been improved.

Finally, NIPU-2 showed the best balance in terms of mechanical strength and elongation at break, which showed that the rigid NIPU can be adjusted to a flexible polymer by introducing FDA.

Through the above research, we successfully synthesized the excellent performance waterborne NIPU epoxy hybrid coating, further expanding the application potential of environmentally friendly non-isocyanate polyurethane.

Future research will focus on the optimization of synthesis process, formulation and final application performance.

The author's opinion:

1.

With the increasing awareness of environmental protection, safety and health, the development and application of non-isocyanate polyurethane have received extensive attention.

2.

However, it is worth noting that non-isocyanate polyurethane, due to the cyclocarbonate/amine reaction method, the product viscosity may be higher, and the solid content of the final product is lower; for water-based resins, the higher the solid content, the better the performance .

At the same time, the traditional polyurethane synthesis reaction time may only need 3-6h to obtain the desired polyurethane, but the synthesis reaction time of non-isocyanate polyurethane is longer.

3.

Therefore, although non-isocyanate polyurethane presents a good application prospect, the current domestic and foreign research on non-isocyanate polyurethane is not systematic and in-depth, and there are still many difficulties to overcome in real industrialization.

The above is the author’s family statement, for reference only.

If you have any questions, you can leave a message under the official account.

Reference materials:

ZhangC, Wang H, Zhou Q.

Waterborne isocyanate-free polyurethane epoxy hybridcoatings synthesized from sustainable fatty acid diamine[J].

Green Chemistry,2020,22(4).

.