-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

As an important market segment of industrial coatings, automotive coatings are both in terms of market size, industry growth, profit margins, and other investment attractiveness, or in terms of product innovation, brand enhancement, and customer stickiness.

Major manufacturers in the global automotive coatings market use more space than ordinary industrial coatings

In 2019, the global automotive coatings market was worth US$18 billion, accounting for 13% of the coatings industry.

China's automotive coating production growth rate will gradually recover

China is the region with the most concentrated production and sales of automotive coatings in the world.

In 2020, China's automobile production and sales will be greatly affected by the epidemic.

The growth rate of China's auto refinish paint will be slightly faster than that of the original paint

According to the basic application scenarios, automotive coatings can be divided into automotive original paints (OEM), automotive refinishing paints, interior and exterior parts coatings, and PVC stone-resistant coatings.

According to the differences in sales channels, OEM vehicle coatings, interior and exterior coatings, and PVC anti-stone-strike coatings are mainly for automotive OEM manufacturers, and their scale growth is highly correlated with new car production and bicycle coating consumption.

In terms of the growth of OEM paints, the output of new cars is the most direct decisive factor.

The current consumption of automotive bicycle paint is usually 10~18 kg.

Due to the reduction of paint film thickness caused by the improvement of coating performance, the improvement of coating resin performance and the improvement of coating utilization rate caused by advanced coating technology, the overall trend in the future is to gradually increase the amount of bicycles.

cut back.

However, no matter from the perspective of the production process of automotive coatings itself or the process maturity of the coating process, there is limited room for reduction in the consumption of bicycle coatings in the next 5 years, which is expected to be 1% to 3%, which will have little impact on the overall growth of the coatings market.

Automotive refinish paint is mainly used in the parts repair and sheet metal process of the automotive aftermarket.

It is mainly targeted at retail channels such as automotive 4S stores and auto repair shops.

Its key driving factors include the growth of car ownership, traffic accident rate and consumers' car repair habits Wait.

Among them, due to the reform of automobile insurance rates, stricter traffic management levels, overall improved driver quality, and the decline in the frequency of car usage caused by serious congestion, etc.

, all factors will bring about a decline in traffic accident rates, thereby reducing the consumption of refinish paint.

However, the marginal effects of these secondary factors have rapidly diminished in recent years, and their future influence will be weak.

In 2019, the national car ownership reached 260 million, and China's car ownership per 1,000 people has just exceeded the global average, and there is still huge room for improvement in the future.

At the same time, positive factors such as the gradual liberalization of the post-modification market and the pursuit of personalized car decoration by consumers will be more conducive to the growth of refinish paint consumption.

As China's auto stock market matures, it is expected that the growth rate of auto refinish paint will be slightly faster than that of original paint, and its proportion will increase from the current 42% to 45% in 2025.

China's water-based automotive coatings will grow faster than other coatings

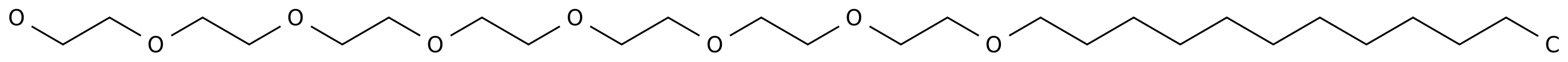

Automotive coatings can be divided into solvent-based coatings, water-based coatings, powder coatings and light-curing coatings according to the product form.

Traditional automotive coatings use organic solvents as diluents and contain a large amount of volatile organic compounds (VOCs), which can cause harm to the human body through inhalation or skin contact.

In recent years, the automotive industry has released the “Road Map for Reduction of Volatile Organic Compounds in the Automotive Industry”, which puts forward the targets, technical routes and demonstration cases for the reduction of VOCs in the automotive industry.

The VOCs emissions per unit painted area of passenger cars put forward clear requirements for reduction.

Water-based automotive coatings use water as the main solvent, and their emissions are reduced by 60% to 70% compared to solvent-based coatings.

In order to meet environmental protection requirements, the primers and topcoats of automotive coatings are gradually developing in the direction of water-based and high-solid.

At present, powder coatings and light-curing coatings have been maturely applied to auto parts and some high-end body coatings.

There is still room for popularization in the future, but their proportion will be relatively stable compared to the strength of water-based coatings.

It is expected that the growth rate of China's water-based automotive coatings will be faster than other coating types, and its proportion will increase from the current 46% to 49% in 2025, mainly replacing some solvent-based coatings.

The proportion of film-forming substances in automotive coatings will be basically stable in the next 5 years

According to the main film-forming substances, automotive coatings are mainly divided into polyurethane type, epoxy type and acrylic type.

Other types also include amino resins, alkyds and polysiloxanes.

、,。,,,。

,,、、,、、,,。

、,,,,。

,,5,。

10、

,。,,。

,,OEM。。,BASF、PPG、,、、、,。,、、。,,、、、,,。

10、,20,,,。,,,,,,。

: