-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

1.

The current situation of world supply and demand: Asia has the largest production capacity and the highest proportion of consumption

In 2020, the world's propylene oxide (PO) production capacity will be approximately 11.

2 million tons per year, of which Asian production capacity accounts for approximately 45% of the world's total production capacity, which is the region with the largest production capacity in the world; Western Europe accounts for approximately 24%; North America accounts for approximately 22%

In 2020, the world's propylene oxide consumption will be approximately 9.

3 million tons

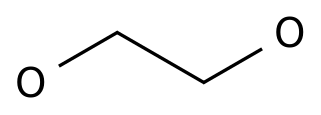

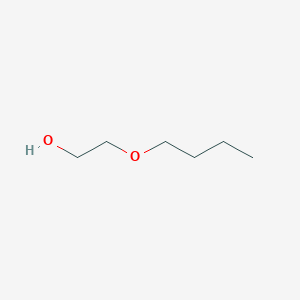

The main application areas of propylene oxide in the world include polyether polyol (PPG), propylene glycol, 1,4-butanediol and propylene glycol ether, etc.

Among them, the largest consumption area is PPG, and there is little difference in the consumption structure between regions

2.

The status quo of domestic supply and demand: the gap between domestic supply and demand still exists

2.

1.

There are mainly 5 types of propylene oxide production process technologies, namely the traditional chlorohydrin method and the advanced co-oxidation method (propylene oxide/SM method, propylene oxide/TBA method), cumene oxidation method (CHP propylene oxide method) ), hydrogen peroxide oxidation method (HP propylene oxide method) and O2 direct oxidation method, of which chlorohydrin method and co-oxidation method are currently the most widely used technologies

.

In 2020, the chlorohydrin method will account for about 50% of the domestic propylene oxide production capacity, and the rest will be the co-oxidation method, HP propylene oxide method and CHP method

2.

2.

Manufacturers: Centralized production capacity in East China

In 2020, there will be 19 domestic propylene oxide producers (see Table 2 for details), 13 of which are located in East China, and their production capacity accounts for 69.

3% of the country's total production capacity

At present, domestic chlorohydrin propylene oxide production enterprises are mainly located in Shandong and Jiangsu provinces

.

The production cost of chlorohydrin propylene oxide is low, but the pollution problem limits the further development of this technology

Among the 4 companies using co-oxidation technology, Zhenli Chemical and CNOOC Shell used propylene oxide/SM technology, and the technologies were from Lyonder and Shell; Yantai Wanhua and Jinling Huntsman used propylene oxide/ MTBE technology, technology comes from Huntsman

.

Among the enterprises using HP propylene oxide process, Sinopec Changling's 100,000-ton/year demonstration device is Sinopec's own technology

.

2.

3.

Consumer sector: Polyether polyol is the largest consumer sector

In 2020, China's propylene oxide consumption is about 2.

99 million tons, and the consumption is mainly concentrated in the fields of polyether polyols, propylene glycol and propylene glycol ethers.

Among them, the consumption of polyether polyols accounts for 70%

.

2.

4.

Supply-demand relationship: the gap between supply and demand still exists

In 2020, China's propylene oxide production capacity will be 3.

29 million tons per year.

Affected by the new crown pneumonia epidemic, the average operating rate of the installations will be 77%, and the output will drop by 330,000 tons year-on-year

.

In the same year, the domestic consumption of propylene oxide was 2.

99 million tons, a year-on-year decrease of 10%

.

In 2020, the supply and demand gap of propylene oxide in China is 467,000 tons

.

The supply and demand situation of China's propylene oxide from 2015 to 2020 is shown in Figure 2

.

3.

Domestic outlook : production capacity is steadily increasing, and propylene oxide is expected to become self-sufficient in the future

3.

1.

Supply forecast: There are more new capacity, mainly HP propylene oxide method and propylene oxide/SM method

According to statistics, there are 24 propylene oxide projects under construction in China, with a total production capacity of about 6.

15 million tons per year.

The projects are mainly distributed in East China, South China and North China

.

The "Industrial Structure Adjustment Guidance Catalog" (2019) clearly proposes to "eliminate serious environmental pollution chlorohydrin production of propylene oxide technology", so the proposed projects mainly adopt HP propylene oxide method and propylene oxide/SM method.

.

Regardless of the elimination of the existing chlorohydrin process equipment, it is estimated that by 2025, the domestic production capacity of propylene oxide will reach 9.

43 million tons per year

.

See Table 3 for details of China's propylene oxide projects under construction

.

3.

2.

Consumption forecast: In the future, domestic consumption will still be dominated by polyether polyols

It is predicted that the domestic consumption of propylene oxide will continue to grow in the future, and the consumption will reach 4.

05 million tons by 2025, with an average annual growth rate of 6.

3% from 2020 to 2025

.

Among the main downstream polyether polyols of propylene oxide, the production of basic soft and hard foam polyethers is large, and it is expected that the future support for the consumption of propylene oxide will still be relatively large

.

In order to increase the added value of products, many polyether factories are undergoing structural transformation, increasing the development of high-activity, high-molecular-weight, and high-value-added polyethers.

In recent years, the production capacity of POP and high-resilience polyethers has increased significantly, but the consumption of propylene oxide in the short term The amount will still be lower than the base polyether

.

China currently has 18 new planned polyether polyol projects with a total production capacity of 2.

97 million tons per year.

If these projects are successfully put into production, it is estimated that by 2025, the consumption of propylene oxide will reach about 2.

8 million tons

.

Propylene glycol is mainly used to produce unsaturated resins.

In 2020, affected by the global epidemic, consumption in this field has dropped by 6.

7% year-on-year.

It is expected that consumption will gradually recover in the next 5 years.

It is estimated that by 2025, the consumption of propylene oxide in this field It will be around 450,000 tons

.

Propylene glycol ether is the third largest consumption area of propylene oxide.

It is estimated that by 2025, the consumption of propylene oxide in this area will be around 220,000 tons

.

Propylene oxide accounts for a small proportion of the consumption of other downstream chemical products.

In addition, flame retardants, cellulose and other products are affected by environmental governance inspections, and the consumption of propylene oxide may show a downward trend in the future

.

3.

2.

Supply-demand relationship: a substantial increase in production capacity, self-sufficiency is just around the corner

With the completion and commissioning of new and planned domestic propylene oxide projects, it is estimated that China's propylene oxide production capacity will reach 9.

43 million tons per year in 2025, and the output will increase substantially

.

In terms of demand, driven by the fields of polyether polyol and propylene glycol, China's propylene oxide demand will reach 4.

05 million tons in 2025, and China's propylene oxide will be self-sufficient

.

4.

Development suggestions

1.

The domestic propylene oxide is in a rapid development stage, and the newly-built production capacity is mainly based on the HP propylene oxide process and the propylene oxide/SM process

.

With the completion and commissioning of the proposed projects under construction, China's propylene oxide production capacity is expected to meet domestic demand, and it is rich.

The traditional chlorohydrin process will gradually be phased out.

The industry needs to pay attention to the risk of overcapacity

.

2.

The domestic propylene oxide consumer market will continue to be concentrated in the East China market dominated by Jiangsu and Shandong.

The consumer areas are mainly downstream industries such as polyether polyols, propylene glycol and propylene glycol ethers

.

When companies deploy propylene oxide, they should also plan downstream products to reduce sales pressure

.

Transfer from: "China Chemical Industry Information" magazine