-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

0Introduction

Powder coating low temperature curing and ultra-low temperature curing are the main direction and main goal of the current raw material manufacturers and powder manufacturers research and development, its advantages not only to meet customer demand for on-site applications, but also in response to national energy conservation and emission reduction policies, and its application areas such as engineering machinery (ACE) industry, medium density fiberboard (MDF) and 5G special thermal materials.

At present, domestic and foreign outdoor low-temperature curing anti-light powder coating research is rarely reported, and domestic outdoor low-temperature curing detergent suppliers are also in the initial research and development stage, and outdoor temperature curing detergent in low-temperature curing conditions play little role.

the current stage of the common outdoor low-temperature curing anti-light powder coating production process for hydroxyacetalamide (HAA) or isocyanate tri-shrink glyceride (TGIC) two-part dry mixed light, its luster can not be achieved without light; A process is a step-by-step high and low acid value low temperature curing and demulation, can achieve this technology of raw materials manufacturers are few, and simple low temperature curing detergent products are still in the development stage, there are still many difficult problems to overcome

the author, with the support of raw material manufacturers and peer elites, has developed an outdoor ultra-low temperature curing (140 degrees C x15min) anti-light powder coating. It has been applied in the fields of lighting and outdoor furniture and has been widely recognized by end users.

1 Outdoor low temperature (160 degrees Cx15min) anti-light powder coating research progress

1.1 HAA-TGIC double-group dry mix low temperature de-lighting

HAA double-part dry mixed low-temperature light-absorbing technology is more mature. Manufacturers such as Allnex, DSM and Synthomer have such products. Among them, the dry mixed low temperature lighting technology can achieve a gloss of 15%, the surface is delicate and flat, TGIC double-group dry mixed low temperature lighting technology is difficult, because of its poor reaction rate, difficult to control, with such products only Allnex, DSM (DSM) and so on.

1.2 . One-step method high and low acid value low temperature dwindle

At present, one-step method high and low acid value normal temperature fading has mature products, but one-step low temperature de-glorification is still rarely reported. Allnex and DSM have only recently had the technology, with a white gloss of 20% (60 degrees).

1.3 . Low-temperature curing detergent

Currently, outdoor low-temperature curing detergent domestic manufacturers are still in the research and development stage, although the gloss in low-temperature conditions can be matte, but its mechanical performance is very poor, simply can not meet customer demand, and only one or two foreign countries have just released outdoor low-temperature curing (160 degrees Cx15min) anti-lighting new products.

2 Experimental part

2.1 formula raw materials

This paper by selecting imported low-temperature polyester resin and special additives with imported low-temperature anti-lighting agent to make outdoor ultra-low-temperature curing anti-light powder coating, and compared the differences in materialization performance between different types of curing agents and astrogenic polyester resins. The raw materials and basic ingredients used are shown in Table 1.

Table 1 Outdoor ultra-low temperature curing anti-light powder coating formula

2.2experimental equipment

experimental equipment: electronic balance, mixer, extruder, grinder, electrostectonic spray gun, oven, film thickness meter, gloss instrument, impactor, bender, cup surropse, UVB aging box, PCI standard plate.

2.3 . Experimental methods

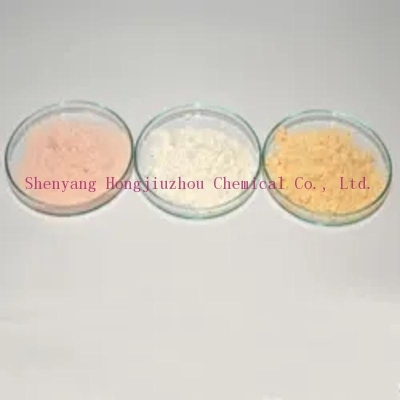

According to the design formula A, B, C, said to take resin, curing agent, anti-light agent, a variety of additives and pigments for pre-mixing, melt extrusion, cooling crushing, grinding powder, and then with electrostature gun spray plate curing to produce outdoor ultra-low temperature curing anti-light powder coating model, curing conditions of 140 degrees C x15min. The resulting model is cooled to room temperature for various performance tests. The main performance is shown in Table 2, and the mechanical performance test model picture is shown in Figure 1.

2 Outdoor ultra-low temperature curing anti-light powder coating main performance indicators

. A formula mechanical performance test

impact test bar bend test cup burst test

Figure 1 mechanical performance test

Figure 1 for A formula mechanical performance test model picture, after a large number of different raw materials and different dosing ratio formula test comparison: A formula used in the type of raw materials and dosing ratio is the best formula, its light performance, mechanical performance, weather resistance and surface fine smoothness is the best.

3 Results and Discussion

This paper is based on continuous optimization of the formula to achieve excellent leveling, excellent mechanical performance, excellent lighting and excellent weather resistance of outdoor ultra-low temperature curing powder coating.

By comparing different types of curing agent 1 and curing agent 2 can be found: both of the ultra-low temperature anti-light powder appearance leveling delicate degree is relatively excellent, curing agent 1 made of ultra-low temperature anti-light powder has more excellent mechanical properties, and curing agent 2 made of ultra-low temperature powder has more excellent de-lighting performance.

By comparing low temperature curing and normal temperature curing polyester resin, it can be found that there is no significant difference between the mechanical and weather-resistant properties of ultra-low temperature de-lighting powders, but the ultra-low-temperature de-lighting powders made from low-temperature cured polyesters have better leveling properties and a smoother and more delicate surface.

also tested several outdoor low-temperature anti-lighting agents provided by domestic suppliers, although its de-lighting performance and leveling performance can meet the research requirements, but its mechanical performance is very unsatisfactory, not repeated here.

4 Conclusion

This paper introduces in detail the progress of the research on outdoor low temperature curing (160 degrees C x15min) anti-light powder coating and its de-lighting method at home and abroad, and further introduces the outdoor ultra-low temperature curing (140 Cx15min) anti-light powder coating development process and chemical and chemical properties, by testing the product's outdoor weather resistance to meet the Requirements of TheQualicoat class 1 performance indicators, can be widely used in building materials, outdoor furniture, display cabinets, lighting and other industries.

Because the import of low-temperature polyester resin and imported low-temperature anti-lighting agent just came out, its raw materials are more expensive, end-customers are difficult to accept, so it is more difficult for powder manufacturers to promote, currently only for some high-end customers and high-end markets. At the same time, I hope that domestic polyester manufacturers and anti-light agent manufacturers can increase research and development efforts of such products, as soon as possible domestic, for the domestic market to contribute a force.

Because low temperature and ultra-low temperature curing have obvious advantages of energy saving and environmental protection, can greatly reduce the cost of coating, so outdoor low temperature and ultra-low temperature curing anti-light powder coating has been a key research topic for raw material manufacturers and powder peers. The purpose of this paper is to provide some reference opinions to the peer researchers through the test data, and then to select the appropriate resin and low temperature anti-lighting agent in the subsequent low temperature de-lighting research and development project.

.