-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

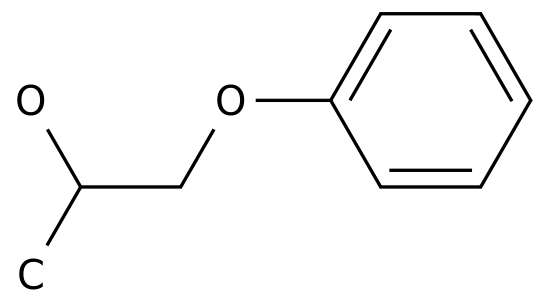

Abstract: A 70/30 hybrid epoxy-cured saturated polyester resin without partial benzoic acid (TMA) was synthesized from raw materials such as benzoic acid, interbenzene, neo-glycol and trihydroxymethyl propane, and the effect of synthetic monomer on polyester resin performance was studied. The polyester resin was prepared into a powder coating, compared with the company's two other hybrid polyester resins, the coating film material content and polyester anti-light performance of the study. The experimental results show that the powder coating prepared with the resin has good leveling and mechanical properties, and by comparing with the performance of some home-produced resins, it is found that the raw material TMA has a great influence on the curing activity and water-resistant properties of powder coatings, while the performance of the resin and similar TMA-containing resins are not very different

0 Introduction

thermooenstic powder coating is mainly composed of resins, curing agents, pigments, additives and so on. Among them, pure polyester powder coating and mixed powder coating is the most important variety in the domestic thermosolystase powder coating market, which is mainly used in household appliances, metal components, metal furniture and other fields. Mixed powder coating is also called polyester-epoxy mixed powder coating, according to the ratio of polyester and epoxy resin curing can be divided into 50/50, 60/40, 70/30 type 3 varieties. The 70/30 hybrid resin is a new product developed on a 60/40 basis to further reduce the amount of curing agent epoxy resin. By reducing the amount of curing agent, the reaction activity of polyester resins must be increased in order to fully cure. In general, the activity of resin can be increased by increasing the amount of active monoliths, but with the increase of the amount of active monoplates such as trihydroxymethyl propane and parabens with higher degrees of branching, the gradual decline of plate leveling performance will occur, resulting in a more obvious orange peel phenomenon.

recent years, the state has adjusted its economic development model and taken environmental protection as the basis for the sustainable development of our economy. Due to environmental protection situation and market demand, domestic powder coating manufacturers on polyester resin products more and more stringent control, some raw materials that do not meet export standards (such as TMA) are gradually replaced by other raw materials. The European Commission issued a resolution (EU) 2018/594 in the Official Gazette formally defining benzene-1,2,4-triacetic acid-1,2-phenyl (partial benzoic acid) as a substance of high concern (SVHCs) ), as a TMA commonly used as a hybrid polyester resin end sterine base, it gives the whole system a higher functional capacity, but because of its skin and mucous membranes have a certain degree of irritation, if the exposure time is prolonged and no intervention, benzodiacytes can cause permanent damage to lung function.

this study synthesized a TMA-free 70/30 hybrid epoxy-cured saturated polyester resin, which was performance-based, and discussed the film-forming material content and the de-lighting properties of polyester resin.

1 Experimental part

1.1 Main raw materials

NPG): LG Group of Korea; Ethylene Glycol (EG): Yangzi Petrochemical; Trihydroxymethyl propane (TMP): Baisto Chemical; 1,4-cyclohexane methanol (CHDM): Shanghai Gideon Chemical; PTA: Hengli Petrochemical; Interphenyl methylene (IPA): Korea ADA: Jiangsu Haili; Single butyl tin oxide (FC4100): Kent, Jiangxi Province; Additives: Jiangxi Kent: Titanium White Powder: Sichuan Longyu; Sabbath: South China Sea Chemistry; Epoxy Resin (E12): Huangshan Jinfeng; Precipitation: Shaanxi Fuhua; Anti-lighting agent (XG603-1A), leveling agent: South China Sea Chemistry; Carbon Black (3MC), Zhengzhou Jinshan Chemical Co., Ltd. All of the above are industrial products.

1.2 Main Instruments

2L Synthetic Reaction Unit: Self-Assembly; NetZSCH, Germany; Cladding Thickness Meter (QNIX4500): Germany; Lacquer Film Impactor: State-owned Tianjin Instrument Tester Plant; Viscosity Meter (CAP2000-H): United States; Glossy Meter (BYK): Germany; Electrostectrectrectrical SprayIng Equipment (K801): Korea, etc.

1.3.1 Basic Formula for

1.3.3 Polyester Resin

table 1 for reference.

1.3.2 Synthesis process

put the formula quantity EG, NPG, TMP, CHDM and FC4100 into the reactor, heating to 50 to 80 degrees C, after the alcohol completely melts, turn on the mixer input formula PTA, at a certain rate of heating up slowly to 250 degrees C, maintain the acid price to the specified range. Then cool down to below 220 degrees C, put into the formulation amount of IPA and ADA, heat up to 235 degrees C and keep warm until the reactant clarification, sampling and testing acid values to meet the standards to enter the next stage. The temperature of the kettle is maintained at about 235 degrees C, -0.09MPa above the vacuum shrinkage of 1.5h, the acid value and viscosity of the standard after cooling to 185 degrees C or less, put in additives, maintain 0.5h after the discharge.

1.4 polyester resin physicolic performance analysis

polyester resin acid value by GB / T6743-2008 detection, viscosity according to GB / T9751.1 - 2008 detection, glass The temperature is detected according to GB/T19466.2-2004, the adhesion is tested according to GB/T9286-1998, and the water resistance is detected according to GB/T1733-1993.

1.5 Preparation of powder coatings

the synthetic polyester resin, curing agent, leveling agent, sabbath, etc. are mixed evenly in proportion to the formulation quantity, extruded by extruder, press, after cooling broken, Oversieve, prepared into a powder coating, sprayed on the treated sample by electrostectrulation spraying, and then placed in a high temperature oven 180 degrees C curing 15min (15min x 190 oC), cooling. The basic formula for powder coatings can be found in Table 2 and the light-out formula in Table 3.

2 results and discussion

2.1 polyester resin formulation design

partial benzodiacirate gives the resin a higher official energy and cross-link density, at the same time in the impact also has excellent performance. Under the premise of giving up the use of benzodiabons, it is particularly important to ensure the stability of polyester resin properties, and to design polyester resin formulation rationally. The use of different synthetic monosomes and different ratios of raw materials will have different effects on the properties of resins.

aromatic acid is beneficial to improve the glass temperature (Tg) of polyester, and parabenic acid (PTA) and interbenzene acid (IPA) are the most important acid synthesis monomers. In order to improve the glass temperature of polyester resin, this experiment investigates the change of viscosity and glassing temperature of polyester resin by increasing the amount of benzoic acid in raw materials. Several different PTA additions were selected for the experiment, and the Tg and viscosity changes of polyester resins were shown in Table 4, and the trend figure was shown in Figure 1.

Figure 1 shows that the viscosity and glassification temperature of polyester resin increases with the increase of PTA dosage, PTA dosage at 59% of the time the glass temperature of the resin exceeds 60 degrees C, if the PTA dosage continues to increase, the first stage of the reaction of polyester resin reaches a transparent time is too long, affecting the reaction process.

hydroxymethylene propane (TMP) is trihydroxyte alcohol, the tri-energy group can significantly improve the polyester resin branching, viscosity and Tg. Increasing the amount of trihydroxymethyl propane will increase the crosslink density of the coating film, so that the resin shows better reaction activity. In this polyester resin synthesis process, the change of viscosity is most obvious, the excessive dosing will obviously reduce the leveling performance of the plate surface, while increasing the difficulty of process control. The effect of TMP dosing on the performance of polyester resins can be found in Table 5.

As can be known from Table 5, with the increase of TMP dosage, the glass temperature of polyester resin has increased, when the addition amount is stable at 0.3% to 0.5%, the subsequent increase in TMP addition has little effect on Tg temperature; When the addition amount reaches 0.5%, the impact and bending performance of the model is reduced, it may be that the excessive dosing makes the coating surface too hard, thereby reducing the flexibility of the coating, causing a decline in mechanical performance.

the addition of curing promoter to polyester resin is to catalyce the open-loop reaction between carboxyl and epoxy, reducing the reaction activator energy, and its dosage directly determines the activity of the curing reaction. The effect of curing promoter dosage on polyester resin properties can be found in Table 6.

As can be seen from Table 6, with the increase of curing promoter dosage, powder coating adhesion time is significantly shortened, the leveling and impact of the model reaches a higher level when 0.8% is added, and the sample leveling of curing promoter is continuously increased, resulting in orange peel phenomenon.

2.2 Effect of film content on model properties

In thermoclytic powder coating, thermostaint resin must be chemically reacted with the curing agent before it can be filmed, the curing agent is an indispensable ingredient in the thermoclytic powder coating, in the mixed powder coating polyester resin and epoxy resin are together as curing agent film, the content of the film substance will affect the performance of the model to a certain extent. The effect of film-forming substance content on model performance can be found in Table 7.

the content of film-forming material affects the cross-link density of the model coating, which in turn affects the gloss, leveling, impact, bending, yellowing and other properties of the model. Table 7 shows that the film material content is similar in 62.8% and 60% when the model gloss is similar, reduced to 55% time gloss slightly decreased; With the decrease of the content of film-forming substances, the degree of wetting and cladding of film-forming fillers decreases, which is reflected in the reduced leveling performance of the model, but the yellow-resistant properties of the model are improved, which may be because the film-forming substances are prone to oxidation or decomposition at high temperatures, while the temperature resistance of inorganic pigments is better than that of organic film-forming materials, and the oxidation decomposition is not easy to occur at high temperatures, which leads to higher film-forming material content, high temperature and yellowing.

2.3 compared with the performance of some home-produced resin high-gloss models

compared the polyester resin A of this study with the company's 70/30 resin B and 60/40 resin C, and examined the differences in performance of the three resins, of which resin B and resin C both contain TMA.

can reflect the degree of curing crosslinking, different curing conditions, powder coating curing degree is different, in general, the higher the curing degree of the coating, the better its performance. The curing degree can be determined by using DSC technology, because the curing reaction is generally a heat release reaction, the amount of heat release is related to the type of resin energy, the number of official groups participating in the reaction, the type of curing agent and its dosage. For a formula-determined resin system, the curing reaction heat is certain, and the curing degree alpha usable formula (1) is calculated: in the

formula, the total heat (J/g) is fully cured;

properties of the three resin coatings are shown in Table 8.

TMA is an important active monomer in polyester resin synthesis materials, which increases the reaction activity of polyester resin. From Table 8, it can be seen that the activity of resinSA, B and C increased in turn, the TMA content in resin C is the highest, and the adhesion time of its powder coating is the shortest, showing high reaction activity. The water-cooking preservation rate of the coating increased with the increase of TMA content, and the three resins showed good levels in adhesion, impact and bending properties. Because the synthetic formula of resin A and C contains more straight-chain alcohol and straight-chain acid, the spatial resistance of the curing product chain segment at high temperature is small, making it easy to flow and cladding, showing good leveling performance. Under the condition of 15min x 180c curing, the curing degree of resin A, B and C is 78%, 83% and 91% respectively, and the curing degree of resin A and resin B is less than 85%.

2.4 Polyester resin anti-light performance ratio to

indoor anti-light powder coating is mainly used in indoor applications, its weather resistance requirements for coatings are not high, this study investigates the resin A and similar products resin B in the partial performance differences in the de-lighting, test results can be seen in Table 9. in addition to its own polyester properties, the de-lighting properties of

polyester resins are also closely related to the formulation design of powder coatings, and the choice of pigments and the degree of matching with anti-lighteners can affect the final plate effect. This study selected a set of anti-light formula for comparative study, Table 9 shows that the two polyester resins under the formula have little difference in performance, model gloss as low as 5 degrees or so but the level is not delicate enough; Due to the low content of film-forming substances, the density of crosslinking decreased after curing, and the coating degree of pigment fillers decreased, showing that the properties of the model have decreased to varying degrees. The anti-light performance of polyester resin corresponds to different anti-light system will show different plate effect, and its investigation process is more complex, which needs to be further studied.

3 Conclusion

study examined the effects of PTA, TMP and curing promoter on polyester resin properties. A polyester resin for a mixture of powder coatings without TMA and Tg at around 60 degrees C was synthesized. The polyester resin prepared powder coating, its film-forming material in about 62.8%, powder coating has good leveling and mechanical properties. Compared with the performance of some home-produced resins, it is found that raw material TMA has a great influence on the curing activity and water-resistant cooking properties of powder coatings, while the resin has little difference with the performance of similar TMA-containing resins. In the field of powder coatings, the environmental protection and high Tg properties of the polyester resin, in line with the requirements of the times will certainly have a broad market application prospects.

.