-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Huang Wei Guo Changpei

Semen resin - Guangzhou Association of Polymers Co., Ltd.

abstract:

using solution polylegis legal synthesis of high-gloss powder coatings with pyrethrenic acrylic resin, discussed the impact of various factors on resin performance, as well as coating curing and powder coating properties. Comparing the performance of synthetic acrylic powder coating with polyester powder coating, the results show that acrylic powder coating has high hardness, strong solvent resistance, water-based cooking resistance, acid-alkaline resistance, weather resistance and other advantages.

1 Foreword

In recent years, China's powder coating industry has developed rapidly, powder coating production ranks among the forefront of the world, the variety gradually complete

. Acrylic resin is a kind of high decorative, high weather-resistant resin, with good aging resistance, corrosion resistance and hardness, high mechanical strength, good color preservation, excellent wear resistance and so on, according to which people developed acrylic powder coating. GMA-type acrylic resin and its powder coating have been industrialized production, but at present, GMA acrylic resin in China is mainly used in powder coatings and carboxyl polyester resin after curing the effect of light reduction and applied to low-gloss work pieces. With the expansion of acrylic powder coating applications, some fields have also put forward new requirements for weather-resistant acrylic powder coatings - high gloss. So my company in the original GMA-type acrylic resin on the basis of the development of a carbie-based acrylic resin, and with epoxy resin with curing, has been high-gloss high weather resistance acrylic powder coating, greatly reduced the cost of powder coatings, fill the domestic high-gloss high-performance acrylic powder coating resin blank, for the development of domestic acrylic powder coating market to provide cost-effective resin raw materials.

2 acrylic resin synthesis

powder coating acrylic resin solid content must be greater than 99%, relative to the molecular mass of 2500 to 10000. Our company uses solution polymerization method to prepare acrylic resin, the process is simple and stable, reaction conversion rate, resin relative to molecular mass and its distribution are easy to control, the acrylic resin is suitable for powder coatings.

2.1 Test raw material

2.2 synthesis process

in the reaction container to add solvents, monosomes, triggers, under the protection of nitrogen at 100 to 130 degrees C and a certain mixing speed of 3 to 6h free-based polymerization reaction, after polymerization removed solvent, get solid acrylic resin, number AR-8823. The synthesis is as follows:

functional acrylic monomers plus (meth) acrylic monomers plus other unsaturated monomers →acrylic resins

The reaction activity of various acrylic monomers is different, so the reaction rate between co-polymer monomers is not consistent, resulting in uneven distribution of monomer units on the chain, which has a great impact on the performance of powder coatings made of synthetic resins, so synthetic process control is very important.

2.3 AR-8823

we tested the properties of AR-8823 acrylic resins, the results of which are below Table 2.

the introduction of

functional monosome (M)AA in the acrylic synthesis process provides the necessary functional groups for acrylic and curing agent reactions. If (M) AA is added, it can improve the hardness and mechanical strength of acrylic powder coating film, and significantly improve the solvent resistance and salt spray resistance of the coating film, but (M) AA dosage is too large, will lead to too large cross-link density of the coating film, coating film leveling difference, orange peel serious, coating film gloss with the increase in acid price and reduce.

At a certain acid value, the size and distribution of the resin molecular weight (official energy) has a great impact on the final performance of the powder coating, when the average molecular weight of acrylic resin is very small, the coating surface leveling is very good, the gloss is very high; Taking into account various factors, by changing the amount of trigger and polymerization temperature to adjust the resin molecular weight in 3000 to 10000, the resulting powder coating has better comprehensive performance of the coating film.

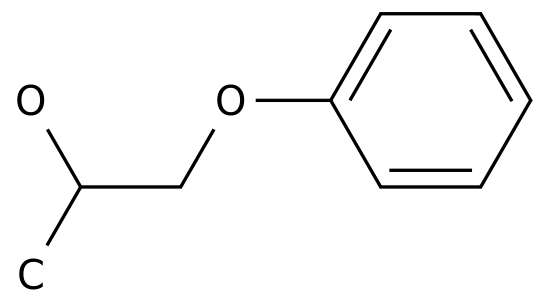

3 Powder coating and coating properties

Acrylic resins with pyrine-based side chains can be cured with Bisphenol A epoxy resins to form a film. As shown in Figure 1, the addition of the appropriate amount of catalyst 2-methylmythylazole, is conducive to the opening of epoxy-based, improve the epoxy-based and niobium-based reaction speed and curing conversion rate, in the powder coating formulation of this catalyst is indispensable. The amount of catalyst determines the gel time of powder coating, the gel time is too short will lead to poor coating flatness, if the gel time is too long coating film will appear flow hanging, poor corner coverage and other ills.

3.1 Powder Coating Reference Formula

In order to facilitate comparison, we use ordinary polyester resin as a control, with AR-8823 and polyester resin, respectively, the preparation of powder coatings, the basic formula is seen in Table 3.

3.2 powder and coating

according to table 3 formula ingredients, dry powder premixed, at 100 to 110 degrees C with a twin screw extruder melting extruded, cooling, preliminary crushing, shredder high-speed crushing, over 180 mesh sieve to get powder coating. Apply the powder coating static electric spray to the surface-treated horse mouth iron plate, bake and cure 15min in a 190C oven, remove the cooling for testing.

it is worth noting that acrylic resin and other powder coating resin substate compatible difference, in the powdering and coating process should be strict isolation measures. In the process of test extrusion, extruder must be cleaned, so as not to cause coating particles, shrink holes and other ills, it is best to use a special production line to prepare acrylic powder.

3.3 coating performance

. The results of the AR-8823 test results for powder coatings made with ordinary polyester are in Table 4.

The test results of table 4 show that the high gloss powder coating leveling of AR-8823 formula is very good, comparable to the leveling of ordinary polyester formulation, 94% of the high gloss can meet the technical requirements in many fields, coating hardness of up to 2H, and most polyester powder hardness can only reach H. The solvent-resistant, boiling water-resistant and alkaline resistance of the coating film is the most outstanding advantage of acrylic powder coating in this study

, the resistance to MEK wipes back and forth up to 30 times, while the normal polyester formula is resistant to MEK wipe results up to 5 times; 3 formula powder coating film can be boiled continuously 32h without losing light, ordinary polyester formula powder coating 32h after water loss is very serious, AR-8823 formula powder is very alkaline resistance, and polyester formula powder resistance is very poor alkaline.

with the increase of resin acid price, coating film crosslinking density increases, hardness increases, gloss decreases, solvent resistance is enhanced. For example, the acid price of AR-8845 is as high as 206, the coating gloss with its preparation is reduced to 4%, the hardness is as high as 3H, and the MEK wipe is greater than 100 times. Most of the powder coatings made of half-light AR-8830 resins range in performance from AR-8823 to AR-8845.

the length of adhesion has a greater impact on the performance of coatings and coatings. The study found that the gelization time of the coating was 32s when the amount of 2-methyl methamphetazole was 0.2% in the experimental formulation of Table 3, and the gelization time of the coating was extended to 60s when the dosing of 2-methyl methamphetumide was 0.1%. In this gel time range, the properties of powder coatings have not changed significantly. However, when the dosing of 2-methyl mide is reduced to 0.05%, the gel time of the coating is extended to 4min, and if no catalyst is used at all, the curing reaction of the coating is very slow, and no more than 10min can be glued. Therefore, 2-methyl methamphetazole catalyst is essential in the formulation.

from the impact resistance of the coating film, the impact performance of the AR-8823 formula has been improved, the coating film is intact and cracking, a good balance between the film flexibility and hardness of the contradiction. However, due to the inherent characteristics of acrylic resin - hard and brittle, resulting in acrylic powder coating impact resistance performance is not satisfactory. Therefore, we recommend that acrylic powder coatings are best used for powder coating of molded products that do not require tailoring after coating.

the use of acrylic AR-8823 with epoxy resin preparation powder coating, because the acrylic resin itself super weather resistance to a certain extent to make up for the poor weather resistance of epoxy resin defects, resulting in powder coating weather resistance is not as good as pure polyester powder, but better than polyester / epoxy powder coating weather resistance.

4 Conclusion

with BPO as the trigger, MMA, EA, BA, ST, i-BoMA, (M) AA as a monogae, at 100 to 130 degrees C in a semi-continuous drip-plus way by synthetic reaction 3 to 6h, adjust the amount of trigger, reaction solvent dosage, monobody ratio and reaction temperature, we synthesize excellent performance of acrylic resin. Powder coatings made from acrylic AR-8823 and epoxy resins have good comprehensive properties, high film gloss, solvent resistance, boiling water resistance, acidity and alkalinity and strong weather resistance.

powder coating made of acrylic resin has a series of advantages, such as high hardness, good chemical resistance, good adhesion, good weather resistance, good electrostitulation coating effect, thin coating and so on. In Europe and the United States, acrylic powder coatings accounted for a large proportion, widely used in household appliances, kitchen cookware, machinery, automobiles, bicycles, motorcycles, aerospace, ships, chemical anti-corrosion, road guardrails, metal furniture, office supplies, construction and decoration and other industries. With the further improvement of powder coating structure in China and the development of export trade, acrylic powder coating has become a hot research topic in recent years. Over time acrylic powder coatings are bound to be more developed.

.