Test method of friction coefficient of soft plastic composite film materials for pharmaceutical packaging

-

Last Update: 2018-03-08

-

Source: Internet

-

Author: User

Search more information of high quality chemicals, good prices and reliable suppliers, visit

www.echemi.com

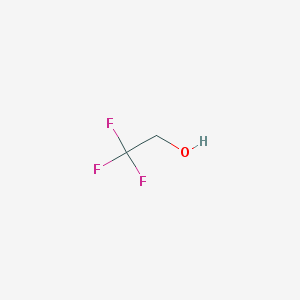

Abstract: friction coefficient is an important factor that affects the convenience and reliability of soft plastic composite membrane materials for packaging pharmaceutical products This paper uses Labthink Languang mxd-02 The friction coefficient instrument tests the friction coefficient of a certain kind of aluminum-plated composite film material for granular drug packaging Through the introduction of the test principle, equipment parameters, application scope, test process and other contents, it provides a reference for enterprises to monitor the smooth performance of soft plastic packaging materials Key words: friction coefficient, dynamic friction coefficient, static friction coefficient, smooth performance, friction coefficient meter, pharmaceutical packaging, soft plastic packaging materials 1 Significance Soft plastic composite membrane material is an important part of pharmaceutical packaging, which can be used to package powder, granular, liquid and other types of drugs Among the many performance indicators of soft plastic packaging, friction coefficient has an important impact on the performance of the material on the machine and whether the packaging can go smoothly If the dynamic friction force of packaging material is too large, the resistance produced in the process of packaging material traction is large, which is easy to cause material tensile deformation, or even be broken The static friction is too small, it is easy to slip in the traction process For the formed soft plastic packaging bags, the friction between the inner materials will also affect the opening of the packaging bags, and the larger friction will lead to the poor opening of the packaging bags Therefore, it is an important guarantee for the smooth packaging process to strengthen the test of the friction coefficient of the soft plastic composite membrane materials for pharmaceutical packaging The friction coefficient of inner and outer surface of the same packaging material is not the same, and the friction coefficient of the same material on different contact surfaces is also different Therefore, when testing the friction coefficient of soft plastic packaging material, the specific friction surface and friction material should be specified according to the actual use Figure 1 common packaging form of pharmaceutical soft plastic 2 The test is based on GB 10006-1988 test method for friction coefficient of plastic film and sheet This standard is applicable to test static and dynamic friction coefficient of non sticky plastic film and sheet with thickness less than 0.2 mm when they slide on their own or other materials 3 Test sample the test sample used in this test is a kind of aluminized composite film material for granular drug packaging It tests the dynamic and static friction coefficient between the outer surface of the sample and the steel plate 4 The test equipment used in this paper is mxd-02 friction coefficient instrument, which is independently developed and produced by Jinan Languang Electromechanical Technology Co., Ltd Fig 2 test principle of mxd-02 friction coefficient instrument 4.1 A certain vertical pressure is applied to the test surface and the friction surface by a certain specification of sliding block, and the force value of the test surface and the friction surface is detected by a precise force value sensor from relative static to relative motion The ratio of Zui large tensile force before relative motion of the two materials, and the ratio of the tensile force value and vertical pressure when relative motion of the two materials are respectively static friction coefficient and dynamic friction coefficient of the test surface Friction coefficient 4.2 scope of application (1) This equipment is mainly used to measure the static friction coefficient and dynamic friction coefficient of plastic film and sheet, textile, non-woven fabric, aluminum foil, aluminum plastic composite film, metal material composite belt for communication cable and optical cable, metal products, rubber, paper, cardboard, woven bag, conveyor belt, wood, coating, brake pad, wiper, shoe material, tire and other materials when sliding, and also can be used for cosmetics , eye drops and other daily chemical products (2) This equipment meets many national and international standards, such as ISO 8295, GB 10006, ASTM d1894, TAPPI T816, etc 4.3 equipment parameters equipment load range is 0 ~ 5N, test accuracy is 0.5 level; stroke can be divided into 70 mm and 150 mm for selection; standard slider mass is 200 g, and other quality sliders can be customized according to the needs of users or relevant standards; test speed is 100 mm / min or 150 mm / min Other test speeds can be adjusted according to the needs; the dynamic and static friction coefficients of the sample can be measured at the same time in one test; the test table and the test slider are demagnetized and remanence tested, effectively reducing the test error of the system; professional software can automatically carry out the statistical analysis of the results of single piece and group test, reanalysis of the original data, and group curve superposition comparison It supports Lystem TM laboratory data sharing system, and manages test reports and test results in a unified way 5 Test process (1) sample preparation: use a sample cutter to cut three samples of 63 mm × 100 mm from the surface of the sample of the aluminized composite film for medical packaging to be tested (2) Sample loading: take one of the samples and clamp it on the slide block with the surface facing outward to make the test area flat Do not touch the test area of the sample by hand during sample preparation and loading Connect the sliding block with the spring to the force sensor of the equipment, and place the sliding block on the steel plate test bench of the equipment without impact The sliding direction of the sample shall be parallel to the traction direction (3) Test: set test speed, test stroke and other test parameters, click the test option, and the test starts After the specimen is stationary on the surface of the test bench for 15s, the relative sliding begins automatically The equipment automatically records the force value in the test process, and calculates and displays the static friction coefficient and dynamic friction coefficient of the specimen after the test Repeat the loading and start-up test, and test the friction coefficient of the other two samples 6 Results the static and dynamic friction coefficients of the aluminum coated composite film samples for the packaging of a certain granule medicine were taken as the average values of the test results of three samples, of which the static friction coefficient was 0.264 and the dynamic friction coefficient was 0.208 7 Conclusion friction coefficient is an important factor that affects the smooth completion of packaging process of pharmaceutical soft plastic composite film In this paper, mxd-02 friction coefficient instrument is used to test the friction coefficient between the outer surface of aluminum coated composite film sample and the steel plate for a granule pharmaceutical packaging The test process is simple, the equipment is easy to operate, and the test results are accurate and reliable Jinan Languang mechanical and Electrical Technology Co., Ltd is a high-tech enterprise specializing in the production, research and development of packaging testing equipment and packaging testing services The existing equipment can test the water vapor transmission, oxygen transmission, nitrogen transmission, tensile performance, peel strength, puncture resistance, solvent residue, nonvolatile content, sealing performance and other indicators of pharmaceutical packaging The more you understand, the more you trust! Labthink is looking forward to enhancing technical communication and cooperation with enterprises and institutions in the industry!

This article is an English version of an article which is originally in the Chinese language on echemi.com and is provided for information purposes only.

This website makes no representation or warranty of any kind, either expressed or implied, as to the accuracy, completeness ownership or reliability of

the article or any translations thereof. If you have any concerns or complaints relating to the article, please send an email, providing a detailed

description of the concern or complaint, to

service@echemi.com. A staff member will contact you within 5 working days. Once verified, infringing content

will be removed immediately.