-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Hard and brittle materials are usually expressed as "tension weakening pressure".

At room temperature, macro-scale hard and brittle materials often exhibit the characteristic that their tensile strength is much lower than their compressive strength, as shown in Figure (1).

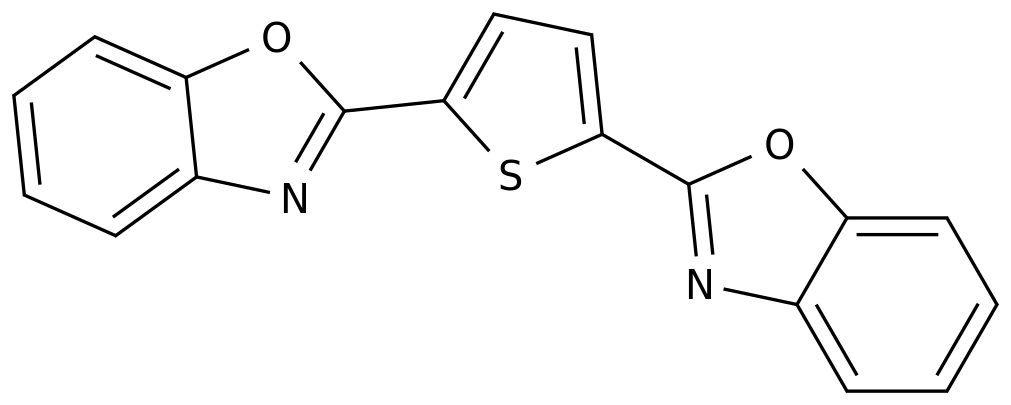

Figure (1) The tensile and compression curves of bulk silicon material; Figure (2) The tensile and compression tests were performed on the same amorphous silicon "tension-compression" micro-sample successively; Figure (3) The tensile stress and the compression of amorphous silicon The shear modulus under compressive stress varies with the amount of strain; Figure (4) The energy barrier that amorphous silicon needs to overcome for shear plastic transformation occurs very differently with tensile-compressive strain.

In order to answer this basic scientific question, researchers at Xi’an Jiaotong University selected amorphous silicon as the research carrier and reduced the size of the material to reduce the probability of defects in the material; in order to eliminate the possible influence of sample differences on the experimental results, use Due to the fracture characteristics of amorphous silicon, a kind of "tension-compression" sub-micron scale sample was designed and prepared: quantitative tensile and compression experiments can be performed on the same sample, as shown in Figure (2).

This paper is composed of Associate Professor Wang Yuecun (co-first author) and Professor Shan Zhiwei (co-corresponding author) of the Micro-Nano Center, and Professor Ding Jun (co-first author) and Professor Ma (co-corresponding author) of the Material Innovation and Design Center Collaboration.

Silicon is not only one of the most important basic materials in the semiconductor industry, but also has a wide range of applications in the fields of photovoltaic cells, liquid crystal displays, flexible electronic devices, and micro-electromechanical systems.

![2,2'-([1,1'-biphenyl]-4,4'-diyldivinylene)bis(benzenesulphon...](https://file.echemi.com/fileManage/upload/cas/7/598b2e35-be55-49b2-b221-2aa5c89c59ce.gif)