-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Sinochem News learned from the press conference of Tianjin Economic and Technological Development Zone held on June 3 that during the "14th Five-Year Plan" period, Tianjin Nangang Industrial Zone will focus on the functional positioning of a world-class chemical and new material industrial base and accelerate the promotion of the region.

At the end of the "14th Five-Year Plan", the output value of the chemical production project in Nangang Industrial Park reached 130 billion yuan, and the tax revenue exceeded 8 billion yuan.

The industrial structure of the Nangang Industrial Zone is expected to be significantly optimized.

During the "14th Five-Year Plan" period, Nangang Industrial Zone will take Sinopec's 1.

(1) Industrial chain of comprehensive utilization of olefins

(1) Industrial chain of comprehensive utilization of olefinsC2 : Use the ethylene produced by the MTO device and the ethylene device to develop products such as ethylene oxide, ethylene glycol, polyvinyl chloride, vinyl acetate, lithium battery electrolyte solvent, polycarbonate, α-olefin, and high-performance polyethylene , And extend downstream to produce coatings, adhesives, surfactants, plasticizers, synthetic lubricants, polycarboxylic acid water reducers, polyether polyols, polyolefin lithium battery separators, high-performance polyolefins, etc.

Carbon two:

C3 : Use the propylene produced by the MTO device and the ethylene device to develop raw materials and products such as propylene oxide, epoxy resin, acrylic acid and esters, acrylonitrile, and high-performance polypropylene.

Carbon three:

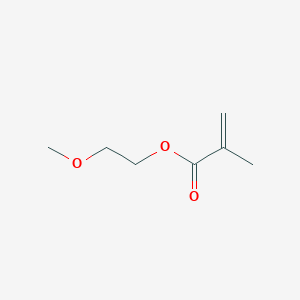

C4: separation of butene-1, isobutylene, butadiene and other raw materials, focusing on the development of methyl ethyl ketone, PMMA, TPU, ABS/ASA resin, SBS and other products.

Carbon Four:

(2) Industrial chain of new chemical materials

(2) Industrial chain of new chemical materialsHigh-performance synthetic resins and composite materials industry chain: will focus on the development of high-performance polyolefins, engineering plastics, modified plastics and alloys, special fibers, composite materials, etc.

High-performance synthetic resin and composite material industry chain:

Electronic information materials: develop high-temperature-resistant halogen-free epoxy resins, insulating films, photosensitive dry films, polyimide flexible copper clad laminates, etc.

Electronic information materials:

Biomedical materials: The development is mainly used in the repair or replacement of built-in artificial bones and joints, hearts, heart valves, esophagus and other tissues and organs, and external artificial heart-lung machines, artificial limbs, artificial teeth and other natural polymer materials; mainly used Synthetic polymer materials used in bone cement, prosthetic joints, sutures, catheters and other diversion tubes, drug slow and controlled release carriers, dental filling materials, etc.

Biomedical materials:

Biodegradable materials: develop PLA and PBAT biodegradable plastics in advance, while focusing on the development trends of other types of biodegradable plastics such as PBS and PCL, and make good project reserves.

Degradable materials:

(3) High-end fine and specialty chemicals

(3) High-end fine and specialty chemicalsElectronic chemicals: focus on the development of photoresist and packaging materials used in semiconductor materials, as well as adhesives and electrolytes used in liquid crystal materials.

Electronic chemicals:

High-end fine chemicals: Utilize raw materials such as ethylene oxide, propylene oxide, and Sinopec's bisphenol A to develop chemical raw materials such as ethylene glycol, propylene glycol, polyether, methyl ethyl ketone, and produce unsaturated resins and epoxy resins.

High-end fine chemicals:

The press conference also disclosed the progress of Sino-Sand Petrochemical’s polycarbonate project and Tianjin Bohua’s “Two Chemicals” relocation project.

The 260,000 tons/year polycarbonate project of Sinosha Petrochemical uses SABIC’s non-phosgene melting process to build two new PC production lines with a production capacity of 130,000 tons/year.

With a total investment of 29.