-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Source: Frontiers of Polymer Science??? Polymer materials have many excellent properties, such as light weight, flexibility, corrosion resistance, easy processing, and low cost.

They are ubiquitous in our lives and play an important role in the development of society.

The role of

.

In recent years, with the development of 5G communications and electric vehicles, the application demand for polymer materials in electronic equipment and electronic systems has continued to surge

.

The voltage withstand performance (dielectric breakdown strength) of polymer materials at room temperature and high temperature is very important for these applications

.

For example, the breakdown strength determines the reliability and durability of polymer insulating materials used for high-voltage power transmission in the power grid

.

The breakdown strength determines the energy density (Ue) of the polymer capacitor

.

Electronic systems in service in harsh environments such as transportation, microelectronics, and aerospace have increasingly demanded polymer breakdown strength over a wide temperature range (>150°C)

.

? In theory, the classical model shows that the inherent breakdown strength of polymer dielectric materials is higher than 1000 MV/m, because polymer dielectric materials have a large energy band gap, and the mean free path of moving charges is small

.

However, the actual value of the breakdown field strength of widely used high-temperature polymer materials, such as polyimide (PI) and poly(etherimide) (PEI), are far lower than the theoretical value

.

Generally, during the molding process of polymer materials, the accumulation of polymer molecular chains is always imperfect, and long molecular chains will be curled, entangled, etc.

, so many defects, such as free volume, are introduced into the amorphous region of the polymer material.

And the structure is disordered

.

The mean free path of these defect regions is greater than the mean free path in the dense polymer structure.

Under the acceleration of an external electric field, the free charge in the defect region will gain higher energy, which will eventually lead to breakdown under a lower electric field

.

? Electrostatic interactions between molecular chains are widespread in all polymers

.

The benzene ring is a key component in the molecular structure of most high-temperature polymers.

The strong interaction between the phenyl groups in different polymer molecular structures can be used to control the polymer chain stacking behavior. .

In the molecular structure of different polymers, the delocalized electrons in the phenyl group may be partially positively charged or partially negatively charged

.

Therefore, by blending two suitable high-temperature polymers, the strong electrostatic interaction between the molecular chains of the two polymers can be used to control the conformation of the molecular chains, induce dense packing of the molecular chains, and reduce the defect sites during the molding process.

, And finally increase the breakdown field strength

.

? Recently, the laboratory of Professor Qiming Zhang from Pennsylvania State University demonstrated this blending strategy through strong electrostatic interaction between chains, which can be effectively applied to several widely used high-temperature polymer dielectric films, including polyimide (PI) and polyetherimide (PEI) (and polyethersulfone, PSU), increase the packing density of the film molecular chain, reduce the defect sites introduced during the molding process, thereby significantly improving their room temperature and high temperature ( 200℃) breakdown strength

.

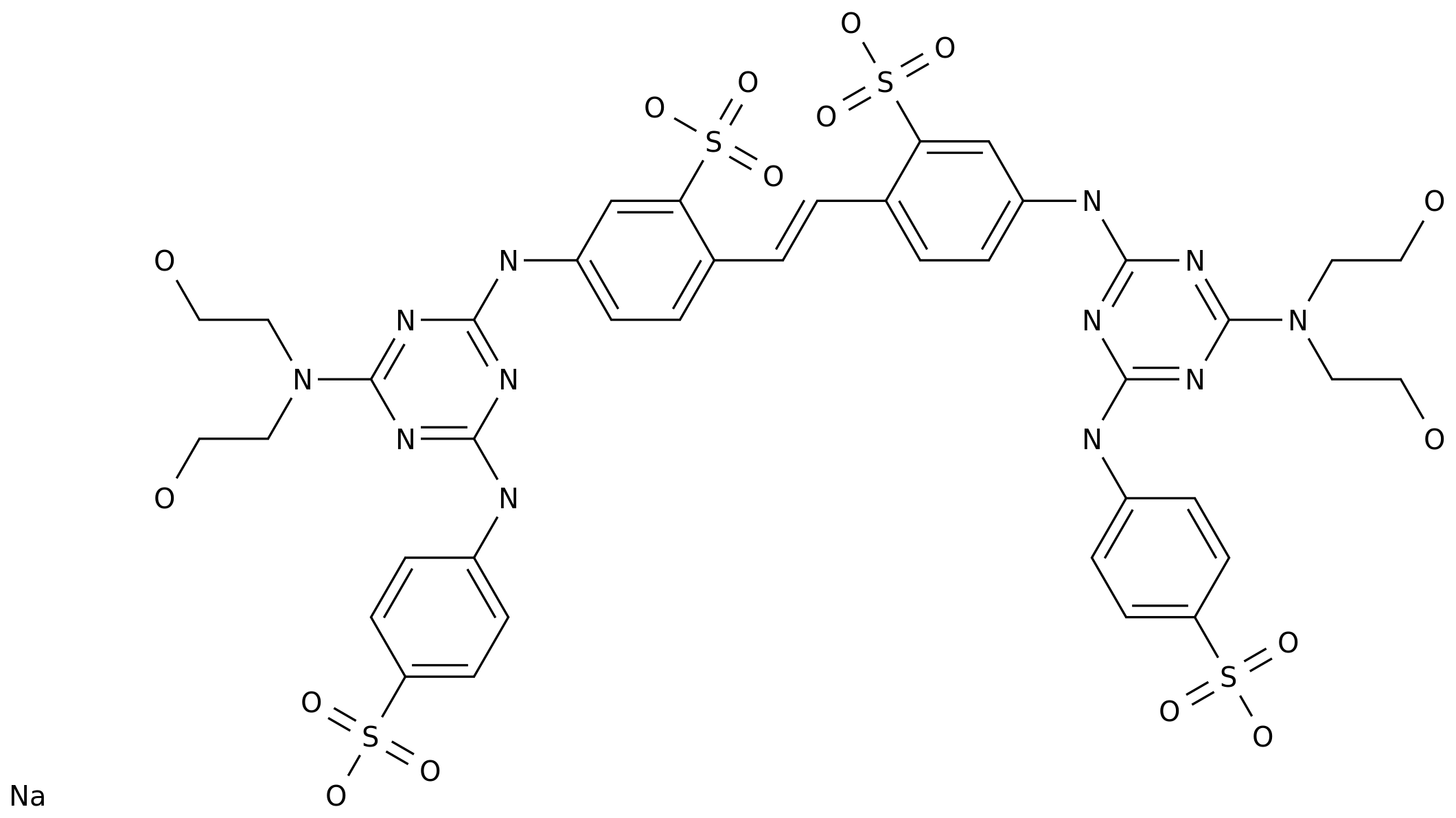

? Molecular chain stacking behavior? As shown in the figure, PI has two strongly positively charged phenyl groups, while PEI has three relatively negatively charged phenyl groups

.

When these two polymers are blended, the strong electrostatic interaction between the molecular chains results in the conformation of the molecular chains in the state of extended chain to the greatest extent, and the chain stacking morphology is densely packed, and the density increases by nearly 10%, thereby reducing the freedom of molecular chains.

Volume and voids

.

Therefore, PI/PEI blends exhibit significantly enhanced breakdown strength in a wide temperature range.

The breakdown strength at room temperature is as high as 1,000 MV/m, and at 200 ℃, it can maintain a breakdown strength of 550 MV/m.

A record high

.

? The dielectric properties of PI/PEI blend films? The strategy proposed in this paper that uses strong electrostatic interactions between molecules for blending can be produced in batches at low cost, which not only provides new molecules for improving the breakdown strength of polymer dielectrics The engineering route can also be applied to many other fields of polymer materials, such as improving the barrier properties of barrier polymers used in packaging, and improving the intrinsic thermal conductivity of polymers used in thermally conductive materials or thermal interface materials

.

They are ubiquitous in our lives and play an important role in the development of society.

The role of

.

In recent years, with the development of 5G communications and electric vehicles, the application demand for polymer materials in electronic equipment and electronic systems has continued to surge

.

The voltage withstand performance (dielectric breakdown strength) of polymer materials at room temperature and high temperature is very important for these applications

.

For example, the breakdown strength determines the reliability and durability of polymer insulating materials used for high-voltage power transmission in the power grid

.

The breakdown strength determines the energy density (Ue) of the polymer capacitor

.

Electronic systems in service in harsh environments such as transportation, microelectronics, and aerospace have increasingly demanded polymer breakdown strength over a wide temperature range (>150°C)

.

? In theory, the classical model shows that the inherent breakdown strength of polymer dielectric materials is higher than 1000 MV/m, because polymer dielectric materials have a large energy band gap, and the mean free path of moving charges is small

.

However, the actual value of the breakdown field strength of widely used high-temperature polymer materials, such as polyimide (PI) and poly(etherimide) (PEI), are far lower than the theoretical value

.

Generally, during the molding process of polymer materials, the accumulation of polymer molecular chains is always imperfect, and long molecular chains will be curled, entangled, etc.

, so many defects, such as free volume, are introduced into the amorphous region of the polymer material.

And the structure is disordered

.

The mean free path of these defect regions is greater than the mean free path in the dense polymer structure.

Under the acceleration of an external electric field, the free charge in the defect region will gain higher energy, which will eventually lead to breakdown under a lower electric field

.

? Electrostatic interactions between molecular chains are widespread in all polymers

.

The benzene ring is a key component in the molecular structure of most high-temperature polymers.

The strong interaction between the phenyl groups in different polymer molecular structures can be used to control the polymer chain stacking behavior. .

In the molecular structure of different polymers, the delocalized electrons in the phenyl group may be partially positively charged or partially negatively charged

.

Therefore, by blending two suitable high-temperature polymers, the strong electrostatic interaction between the molecular chains of the two polymers can be used to control the conformation of the molecular chains, induce dense packing of the molecular chains, and reduce the defect sites during the molding process.

, And finally increase the breakdown field strength

.

? Recently, the laboratory of Professor Qiming Zhang from Pennsylvania State University demonstrated this blending strategy through strong electrostatic interaction between chains, which can be effectively applied to several widely used high-temperature polymer dielectric films, including polyimide (PI) and polyetherimide (PEI) (and polyethersulfone, PSU), increase the packing density of the film molecular chain, reduce the defect sites introduced during the molding process, thereby significantly improving their room temperature and high temperature ( 200℃) breakdown strength

.

? Molecular chain stacking behavior? As shown in the figure, PI has two strongly positively charged phenyl groups, while PEI has three relatively negatively charged phenyl groups

.

When these two polymers are blended, the strong electrostatic interaction between the molecular chains results in the conformation of the molecular chains in the state of extended chain to the greatest extent, and the chain stacking morphology is densely packed, and the density increases by nearly 10%, thereby reducing the freedom of molecular chains.

Volume and voids

.

Therefore, PI/PEI blends exhibit significantly enhanced breakdown strength in a wide temperature range.

The breakdown strength at room temperature is as high as 1,000 MV/m, and at 200 ℃, it can maintain a breakdown strength of 550 MV/m.

A record high

.

? The dielectric properties of PI/PEI blend films? The strategy proposed in this paper that uses strong electrostatic interactions between molecules for blending can be produced in batches at low cost, which not only provides new molecules for improving the breakdown strength of polymer dielectrics The engineering route can also be applied to many other fields of polymer materials, such as improving the barrier properties of barrier polymers used in packaging, and improving the intrinsic thermal conductivity of polymers used in thermally conductive materials or thermal interface materials

.

![disodium 4,4'-bis[[4-anilino-6-[(2-carbamoylethyl)(2-hydroxyethyl)amino]-1,3,5,-triazin-2-yl]amino]stilbene-2,2'-disulphonate CAS NO 27344-06-5](https://file.echemi.com/fileManage/upload/cas/77/e1abc71f-648d-403c-93fe-69b5c9401d56.gif)