-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Performance:

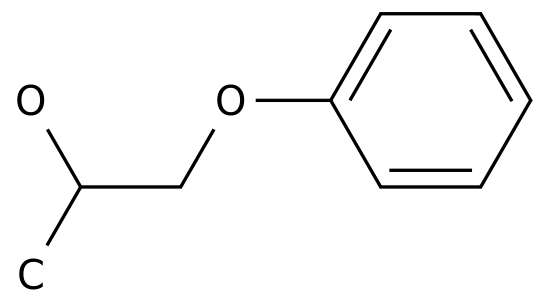

epoxy adhesive system is made of epoxy reinforcers, fillers, etc. High bonding strength, high hardness, good rigidity, acid resistance, alkali, oil and organic solution, small curing shrinkage, can be used as metal, cement, ceramics, glass, stone, wood, thermostate plastics and other materials structural adhesives and building potted materials.

principle analysis

: in

formulation, epoxy resin and PVC resin are the main adhesive components; Boric oil tren fluoride, boron phenyl teflonide, triethyl glycolamine as a curing agent, phosphoric acid as an acidification agent, and the curing promoter and increase the adhesion of metals

.

two-part room temperature cured epoxy adhesive. Apply a certain amount of pressure when the glued surface is coated with this product. it can be cured at room temperature. The curing conditions are: 14-16 seconds at 16.5 degrees Celsius, 7-9 seconds at 25 degrees Celsius, 4-6 seconds at 30 degrees Celsius. Mainly used in a variety of metals and metals, metals and non-metallic, as well as a variety of hard plastic products bonding, with a high bonding strength.

the slowing down of epoxy adhesives: . Although the bonding strength of epoxy adhesive is relatively high, but for some high-strength structural bonding is still insufficient, but also need to further improve the bonding strength, can be slowed down by some of the following ways.1, the use of high-performance epoxy resinsome high-performance epoxy resins, such as AG180, AFG 190, phenolic epoxy resin, like F epoxy resin, BPA S epoxy resin, liquid crystal epoxy resin, TDE 85 (IJ)), 731, alone or mixed with bisphenol A epoxy resin, have a high bonding strength. Liquid crystal epoxy resin is a highly molecularly ordered, deep molecular cross-linking polymer network, which can form a self-reinforcing structure with excellent performance. A small amount of liquid crystal ring maple resin mixed with B144 epoxy resin, the curing material stretch strength and impact strength is obviously thrown out of the island.2, the choice of enhanced curing agentcuring agent on the adhesive adhesive bonding strength has an important impact, the selection of epoxy adhesive curing after the bonding strength of high curing agents, such as diocyanide, interphenyls, diamina diphenyl methane, diamino diphenyl, low molecular polyamide Amines (315, 3051), G11328, end-amino polyether, 105 peptides, methyl hexahydrobenzene, biphenyl diazine/benzene (20/28), 21 ethyl-141 methyl methylene, linear phenol resin, etc.epoxy resin pre-branched with CTBN, with polyetheramine (polyetheramine) as an internal toughening curing agent, using a double toughening system, so that room temperature curing epoxy adhesive room temperature shear strength of 35MPa. 90 - Peeling strength exceeds 3.5kN/m.3, the addition of enhanced fillersfillers reduced the thermal expansion coefficient and curing shrinkage of curing, reducing the internal stress. When cracks occur under overload, the plastic layer with fillers also prevents cracks from expanding, increasing bonding strength. For example, epoxy adhesives for bonding metal structures, adding the right amount of iron powder can improve shear strength. Enhanced fillers are silicon micro-powder, white carbon black, silica ash powder, alumina, ultra-fine aluminum silicate, lightweight oxidation set, talcum powder, sea foam powder, bump bar soil powder, ultra-fine calcined kaolin, iron oxide powder, iron powder, aluminum powder, zinc powder, glass phosphorus tablets, stainless steel scales, dolomite powder and so on.4, inorclemental crystal needs enhancement the wafer is a very small diameter fiber grown in the form of a single crystal under special conditions, with a highly ordered atomic arrangement structure, so that it can be close to the theoretical strength of the price bond between atoms, used to enhance the epoxy adhesive has great potential. Available crystals must be zinc oxide, calcium sulfate, calcium carbonate, aluminum borate, titanium-based, hydroxyphosphate, magnesium hydroxide, alkaline magnesium sulfate, silicon carbide, etc.5, fiber-reinforced glass fiber, carbon fiber, aromatic polyamide fiber (Kevlar fiber), Veron fiber, polyethylene alcohol fiber, polyphenyl ether fiber, stainless steel fiber, basalt fiber, stone fiber, etc. can be enhanced with epoxy adhesive.6, silane coupled agent enhancementadd appropriate amounts of silane coupled agents, such as KH one 560, KH one 550, KH one 580, KH one 590, KH one 792, Nanda 42, Nanda one 73, A11186, A11160, etc., can effectively improve the bonding strength of epoxy adhesive. For example, epoxy adhesive bonded aluminum, added KH 550 (1%) shear strength of 11.6.MPa;7, the use of membrane epoxy adhesivemembrane epoxy adhesive referred to as epoxy film, manufacturing more choice of relatively high molecular quality of bisphenol A solid epoxy resin and multi-official epoxy resin. The film is easy to ensure that the thickness of the glue layer is uniform when bonding, so the bonding strength is very high.

.