-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The open circuit voltage of conventional water-based flow batteries is limited by water electrolysis

.

In contrast, organic solvents have a wider electrochemical window, and redox flow batteries constructed using them also exhibit a higher open circuit voltage, so in theory, higher energy density can be achieved

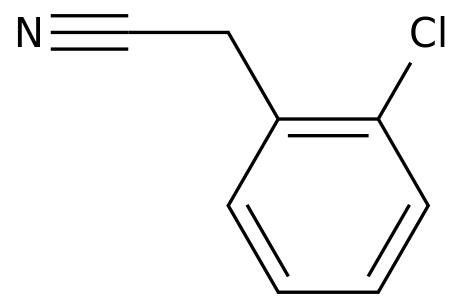

In order to solve the above problems, the team of Li Yongdan and Zhang Cuijuan of Tianjin University recently studied nitrobenzene-based anode materials-nitrobenzene (NB), 2-nitrotoluene (2-NT), and 3-nitrotoluene (3-nitrotoluene).

NT) and 4-nitrotoluene (4-NT)

Figure 1a shows the ratio of 0.

01 M active substance in 0.

1 M tetraethylammonium bis(trifluoromethylsulfonyl)imide (TEATFSI)/acetonitrile (MeCN) at a scan rate of 100 mV s -1 Cyclic Voltammetry (CV) curve .

The half-wave potential of DBMMB is 0.

69 V vs.

The diffusion coefficient (D) and electrochemical kinetic rate constant (k 0 )

of the active material are evaluated by CV and linear voltammetry (LSV) tests .

As shown in Figure 1b, compared with other common active materials, the four active materials have higher D and k 0 , which is conducive to their performance at higher operating currents

Figure 1: a) Cyclic voltammogram of 0.

01 M DBMMB/0.

01 M negative electrode active material in 0.

1 M TEATFSI/MeCN solution .

The scan rate is 0.

1 V s -1 .

b ) Comparison of the kinetic rate constant (k 0 ) and diffusion coefficient (D) of the active material in this work and the literature .

In order to evaluate the effect of the substituents in the actual battery, the mixed anode and cathode materials were cyclically tested in a flow cell

.

As shown in Figure 2a, when 2-NT is used as the anode material, the capacity decays very quickly

Figure 2: a) 0.

1 M DBMMB/0.

1 M anode material (NB, 2-NT, 3-NT or 4-NT) discharge capacity retention rate of flow battery

The rate performance test of the battery is performed under the condition of a current density of 50 mA to 80 mA cm -2 .

For each current density, 5 charge/discharge cycles were tested, and the almost constant capacity indicates that the flow battery has high stability .

For current densities of 50, 60, 70 and 80 mA cm -2 , the average discharge capacity was maintained at 2.

6, 2.

1, 1.

Figure 3 : a) The relationship between the capacity and the number of cycles of the battery from 50 to 80 mA cm -2 .

b) Efficiency at different current densities .

c) IV polarization curve .

d) The cycle efficiency and capacity of a 0.

1 M DBMMB/0.

1 M 3-NT/1.

0 M TEATFSI/MeCN flow battery at 60 mA cm -2 .

In order to take full advantage of the high solubility of DBMMB and 3-NT, a flow battery of 1.

0 M DBMMB/1.

0 M 3-NT/1.

2 M TEATFSI/MeCN was assembled and tested at 80 mA cm -2 .

In 50 cycles, the average CE, VE and EE were 92.

8%, 52.

0% and 48.

2%, respectively (Figure 4a) .

The initial charge and discharge capacity reached 13.

7 and 11.

2 Ah L -1, respectively .

Therefore, the actual energy density of the flow battery reaches 37.

8 Wh L -1 during charging and 18.

7 Wh L -1 during discharging .

The high working current density and actual volume energy density of the flow cell are significantly higher than other reported all-organic non-aqueous redox flow batteries (Figure 4b) .

Figure 4: a) Cycle efficiency of 1.

0 M DBMMB/1.

0 M 3-NT/1.

2 M TEATFSI/MeCN flow battery at 80 mA cm -2 .

b) Comparison of flow battery performance between DBMMB/3-NT and other documents .

In short, they used the high solubility of liquid active materials to develop a flow battery with high energy density

.

The positive active material is 2,5-di-tert-butyl-1-methoxy-4-[2'-methoxyethoxy]benzene (DBMMB), and the negative active material is 3-nitrotoluene (3-NT )

.

In acetonitrile (MeCN) as the solvent, tetraethylammonium bis (trifluoromethanesulfonyl) imide salt when (TSATFSI) as the supporting electrolyte, open-circuit voltage of the battery is composed of V 2.

25

.

Using Daramic-250 as the battery separator, the average discharge capacity of the battery with 0.

1 M active material at a current density of 60 mA cm -2 for 50 cycles is 2.

25 Ah L -1 , CE=93.

7%, VE=76.

6%, EE=71.

8 %

.

When the active material concentration is increased to 1.

0 M and the current density is 80 mA cm -2 , the first charge capacity of the battery reaches 37.

8 Wh L -1 , the average CE=92.

8%, VE=52.

0%, and EE=48.

2% for 50 cycles

.

Related Links

https://pubs.

acs.

org/doi/full/10.

1021/acsami.

1c05564