-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Articular cartilage is a load-bearing tissue at the end of the long bones of the joint.

Its smooth surface can reduce the friction between the adjacent two bones and cushion the vibration generated during exercise

.

Although the low friction of cartilage is largely due to the fluid pressurization that can withstand a considerable portion of the load

.

But lubricating molecules also play an important role in regulating friction, especially in surface-to-surface contact in the lubrication boundary mode

.

The components in synovial fluid include hyaluronic acid, synovial fluid protein and surface active phospholipids, which play an extremely important role in the boundary lubrication of cartilage

.

For human articular cartilage, its long-term lubricating properties mainly come from the exposed non-fluid, high water content head group of lecithin lipids

.

? Hydrogel is a hydrophilic polymer chain network that can absorb large amounts of water or biological liquids

.

It, like cartilage, is mainly composed of water

.

Its low permeability and low friction properties have made hydrogel materials widely studied as a cartilage substitute

.

In biomedical and other application scenarios, the hydrogel will slide on the countersurface, so it must have excellent lubricating properties

.

Under normal circumstances, the lubricity of hydrogel mainly comes from the fluid or solvated surface phase, which is different from human cartilage

.

? Recently, inspired by the lipid boundary layer of joints, Ronit Goldberg and Jacob Klein of the Weizmann Institute of Science in Israel collaborated to design hydrogels with a low concentration of lipids (phosphatidylcholine).

These hydrogels The glue continuously leaks lipids to the surface to form a self-lubricating layer.

Compared with non-lipid hydrogels, friction and wear are reduced by 80% to 99.

3%, and the lubrication mechanism of human joint cartilage is mimicked and improved, even if it is gel After the glue dries, replenish moisture, this lubricating effect still exists

.

This method has universal applicability and has greatly promoted the application of hydrogel materials in the field of biomedicine, tissue engineering, biosensors and even contact lenses.

Related papers are titled "Cartilage-inspired, lipid-based boundary-lubricated hydrogels" , Published in the latest issue of "Science", the first author is Lin Weifeng

.

??? When the hydrogel slides on the dual surface, the lipid vesicles inside the hydrogel will release a lipid layer on the surface of the gel.

The head group of this lipid layer has a high water content, which is greatly reduced.

The friction coefficient of the hydrogel surface

.

When the hydrogel is worn out due to friction, this boundary lubricant layer can self-renew

.

In addition, the concentration of lipids doped into the hydrogel material is very low and can be adjusted as needed, which has little effect on the mechanical properties of the hydrogel itself

.

??? Ronit Goldberg and others have tested a variety of hydrogel materials including biological hydrogels and synthetic polymer hydrogels (some materials are very different from the commonly used pHEMA), and the results show that lipids are incorporated It can effectively reduce the friction of the hydrogel

.

In addition, the researchers also tested the mating surfaces other than steel materials, and again found an effective reduction in friction

.

Finally, they studied sliding speeds in the range of more than three orders of magnitude, and measured nearly constant friction coefficients, proving that this boundary mode lubrication is effective

.

More importantly, the author's surface sliding drives the release of lipids in lipid vesicles on the surface of the gel, which is crucial for the formation of the surface lipid layer

.

And when the hydrogel is slightly worn due to friction, the boundary lubricant layer will renew itself

.

However, the lubrication effect of soaking and washing the hydrogel or putting it in a solution to apply lipids on the outside is far less effective than doping lipids inside the hydrogel material

.

Compared with the lipids in the vesicles, the lipids in the surrounding solution cannot easily enter the gel-dual surface interface

.

In addition, lipid vesicles did not change the mechanical properties of the hydrogel

.

The author also stated that the doping concentration of lipids can be adjusted as needed, thus realizing the adjustment of the hydrogel's lubricating ability and durability

.

However, considering that the self-renewal of hydrogel is based on wear and tear, the overall life of the material may be affected, so it needs to be considered according to different applications

.

??? Finally, after putting this hydrogel material in a 60 ℃ oven to completely dry, and then replenishing water, the hydrogel can still maintain lubrication

.

This powerful property has a positive impact on the storage and use of hydrogels under harsh conditions

.

? Summary: Ronit Goldberg et al.

achieved the self-lubricating effect of different hydrogel materials by doping with lipids, while retaining the mechanical properties of the materials themselves

.

These materials have great potential in applications such as biomedicine, tissue engineering, biosensors and even contact lenses

.

More importantly, in addition to lubrication, these hydrogels can perform more complex biological functions, such as drug delivery devices, anti-inflammatory agents, or immune response modifiers

.

In fact, this discovery has potential applications in many fields related to biology and medicine

.

We will wait and see where future research and applications will go .

Its smooth surface can reduce the friction between the adjacent two bones and cushion the vibration generated during exercise

.

Although the low friction of cartilage is largely due to the fluid pressurization that can withstand a considerable portion of the load

.

But lubricating molecules also play an important role in regulating friction, especially in surface-to-surface contact in the lubrication boundary mode

.

The components in synovial fluid include hyaluronic acid, synovial fluid protein and surface active phospholipids, which play an extremely important role in the boundary lubrication of cartilage

.

For human articular cartilage, its long-term lubricating properties mainly come from the exposed non-fluid, high water content head group of lecithin lipids

.

? Hydrogel is a hydrophilic polymer chain network that can absorb large amounts of water or biological liquids

.

It, like cartilage, is mainly composed of water

.

Its low permeability and low friction properties have made hydrogel materials widely studied as a cartilage substitute

.

In biomedical and other application scenarios, the hydrogel will slide on the countersurface, so it must have excellent lubricating properties

.

Under normal circumstances, the lubricity of hydrogel mainly comes from the fluid or solvated surface phase, which is different from human cartilage

.

? Recently, inspired by the lipid boundary layer of joints, Ronit Goldberg and Jacob Klein of the Weizmann Institute of Science in Israel collaborated to design hydrogels with a low concentration of lipids (phosphatidylcholine).

These hydrogels The glue continuously leaks lipids to the surface to form a self-lubricating layer.

Compared with non-lipid hydrogels, friction and wear are reduced by 80% to 99.

3%, and the lubrication mechanism of human joint cartilage is mimicked and improved, even if it is gel After the glue dries, replenish moisture, this lubricating effect still exists

.

This method has universal applicability and has greatly promoted the application of hydrogel materials in the field of biomedicine, tissue engineering, biosensors and even contact lenses.

Related papers are titled "Cartilage-inspired, lipid-based boundary-lubricated hydrogels" , Published in the latest issue of "Science", the first author is Lin Weifeng

.

??? When the hydrogel slides on the dual surface, the lipid vesicles inside the hydrogel will release a lipid layer on the surface of the gel.

The head group of this lipid layer has a high water content, which is greatly reduced.

The friction coefficient of the hydrogel surface

.

When the hydrogel is worn out due to friction, this boundary lubricant layer can self-renew

.

In addition, the concentration of lipids doped into the hydrogel material is very low and can be adjusted as needed, which has little effect on the mechanical properties of the hydrogel itself

.

??? Ronit Goldberg and others have tested a variety of hydrogel materials including biological hydrogels and synthetic polymer hydrogels (some materials are very different from the commonly used pHEMA), and the results show that lipids are incorporated It can effectively reduce the friction of the hydrogel

.

In addition, the researchers also tested the mating surfaces other than steel materials, and again found an effective reduction in friction

.

Finally, they studied sliding speeds in the range of more than three orders of magnitude, and measured nearly constant friction coefficients, proving that this boundary mode lubrication is effective

.

More importantly, the author's surface sliding drives the release of lipids in lipid vesicles on the surface of the gel, which is crucial for the formation of the surface lipid layer

.

And when the hydrogel is slightly worn due to friction, the boundary lubricant layer will renew itself

.

However, the lubrication effect of soaking and washing the hydrogel or putting it in a solution to apply lipids on the outside is far less effective than doping lipids inside the hydrogel material

.

Compared with the lipids in the vesicles, the lipids in the surrounding solution cannot easily enter the gel-dual surface interface

.

In addition, lipid vesicles did not change the mechanical properties of the hydrogel

.

The author also stated that the doping concentration of lipids can be adjusted as needed, thus realizing the adjustment of the hydrogel's lubricating ability and durability

.

However, considering that the self-renewal of hydrogel is based on wear and tear, the overall life of the material may be affected, so it needs to be considered according to different applications

.

??? Finally, after putting this hydrogel material in a 60 ℃ oven to completely dry, and then replenishing water, the hydrogel can still maintain lubrication

.

This powerful property has a positive impact on the storage and use of hydrogels under harsh conditions

.

? Summary: Ronit Goldberg et al.

achieved the self-lubricating effect of different hydrogel materials by doping with lipids, while retaining the mechanical properties of the materials themselves

.

These materials have great potential in applications such as biomedicine, tissue engineering, biosensors and even contact lenses

.

More importantly, in addition to lubrication, these hydrogels can perform more complex biological functions, such as drug delivery devices, anti-inflammatory agents, or immune response modifiers

.

In fact, this discovery has potential applications in many fields related to biology and medicine

.

We will wait and see where future research and applications will go .

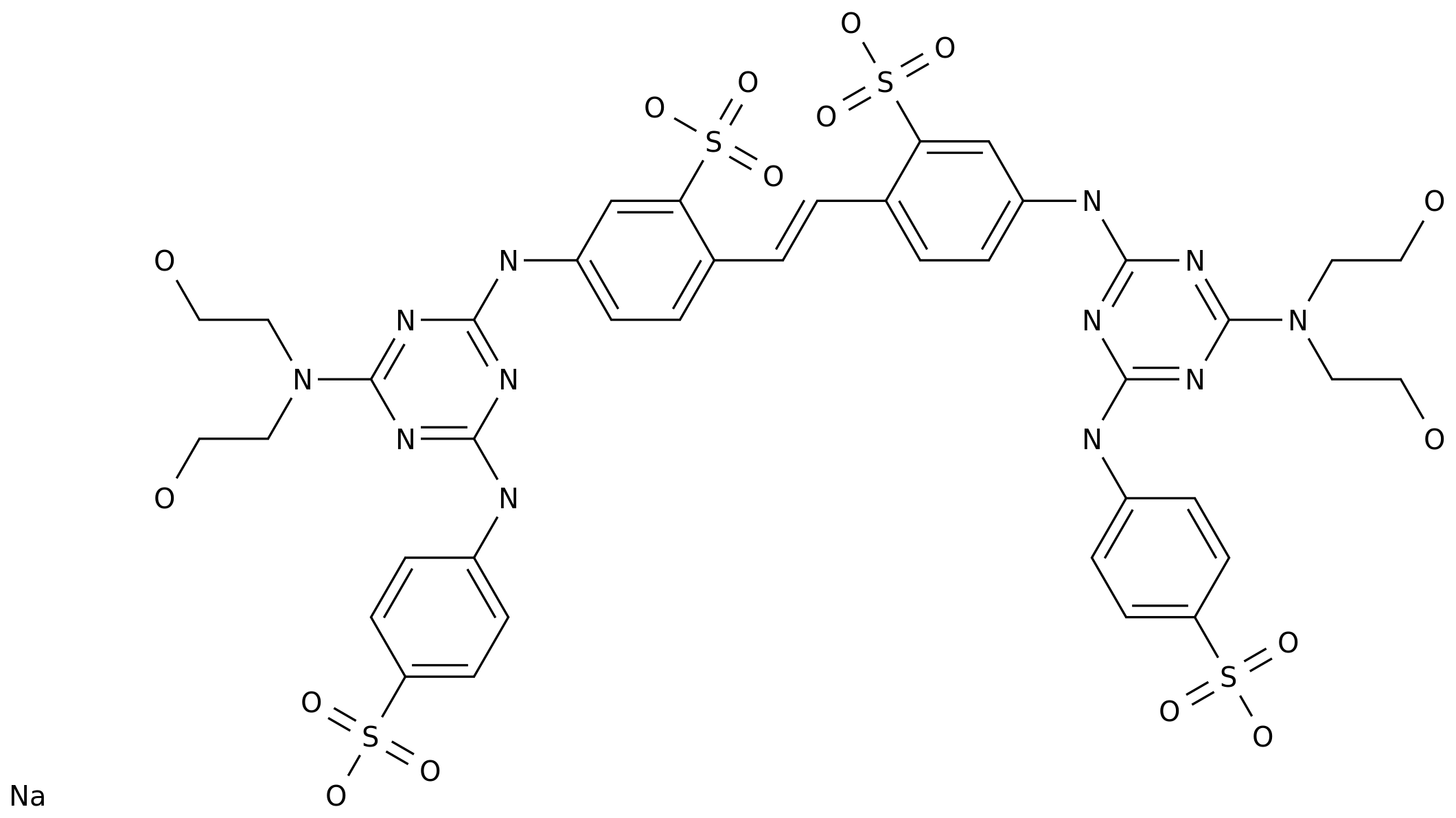

![disodium 4,4'-bis[[4-anilino-6-[(2-carbamoylethyl)(2-hydroxyethyl)amino]-1,3,5,-triazin-2-yl]amino]stilbene-2,2'-disulphonate CAS NO 27344-06-5](https://file.echemi.com/fileManage/upload/cas/77/e1abc71f-648d-403c-93fe-69b5c9401d56.gif)