-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

It is reported that H2 Industries Inc.

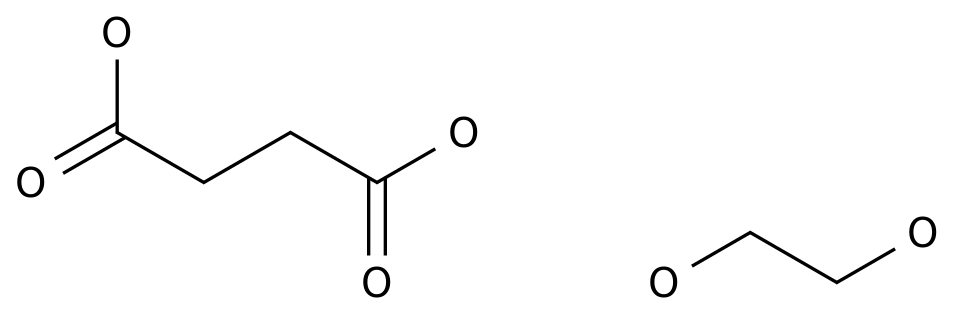

, an American hydrogen production and storage solutions company, announced that it has received preliminary approval from the General Directorate of the Suez Canal Economic Zone (SC Zone) for the development of a 1GW liquid organic hydrogen carrier (LOHC) hydrogen hub

.

After the project is completed, 4 million tons of organic waste and non-recyclable plastics will be processed every year, and the waste, sewage and sludge may be "hydrogenated", and the annual output is expected to reach 300,000 tons

.

Chemical machinery and equipment network hotspots focus on chemical machinery and equipment, an American hydrogen production and storage solutions company, announced that it has received preliminary approval from the General Directorate of the Suez Canal Economic Zone (SC Zone) for the development of a 1GW liquid organic hydrogen carrier (LOHC) hydrogen hub

.

After the project is completed, 4 million tons of organic waste and non-recyclable plastics will be processed every year, and the waste, sewage and sludge may be "hydrogenated", and the annual output is expected to reach 300,000 tons

.

Not only that, the hydrogen plant will also use CCUS technology for carbon capture and seek commercial transactions to better achieve carbon neutrality

.

.

According to industry assessment, this will be "the world's first and largest waste-to-hydrogen plant", located in Egypt

.

.

Waste hydrogen production, this refreshing technology directly binds solid waste treatment and clean energy, will there be a buff bonus?

Many people may have heard this argument.

As a highly efficient way of harmless disposal and resource utilization of solid waste, waste incineration power generation will have some inadequacy of resource utilization under the background that garbage classification has not yet been popularized

.

However, the resource utilization of solid waste is a long chain, interlinked, and it is not so easy to achieve ideal results.

For example, the moisture content of waste directly affects the efficiency of waste incineration

.

As a highly efficient way of harmless disposal and resource utilization of solid waste, waste incineration power generation will have some inadequacy of resource utilization under the background that garbage classification has not yet been popularized

.

However, the resource utilization of solid waste is a long chain, interlinked, and it is not so easy to achieve ideal results.

For example, the moisture content of waste directly affects the efficiency of waste incineration

.

However, waste hydrogen production is not affected by the moisture content of primary waste.

In the process of exploring higher-value and feasible solid waste recycling methods, waste hydrogen production can be regarded as a major breakthrough

.

In the process of exploring higher-value and feasible solid waste recycling methods, waste hydrogen production can be regarded as a major breakthrough

.

"To fully transition from a linear economy to a circular economy requires comprehensive changes", there are many people who hold this view

.

The introduction of any new technology stems from demand, and development relies on the principle of "economic applicability", which is also the core reason why the current waste-to-hydrogen model is not common, or has not been widely popularized

.

.

The introduction of any new technology stems from demand, and development relies on the principle of "economic applicability", which is also the core reason why the current waste-to-hydrogen model is not common, or has not been widely popularized

.

Shengyuan Environmental Protection once mentioned when answering investors' questions that the domestic waste treatment technology pyrolysis gasification hydrogen production has good environmental protection characteristics, which can effectively reduce the generation of compounds and reduce fly ash emissions, but the current industrial application of technology It is still in its infancy, and the cost of hydrogen production is still high

.

Obviously, this is the indisputable status quo

.

.

Obviously, this is the indisputable status quo

.

However, the increasing popularity of waste hydrogen production is also an inevitable trend

.

In 2019, China's first waste-to-hydrogen project was launched in Wuhan, where hydrogen generated during waste incineration was collected and made into hydrogen oil

.

In September 2021, Dongfang Electric Group Dongfang Boiler Co.

, Ltd.

announced that it signed a letter of intent for cooperation in waste-to-energy coupled hydrogen production and hydrogen energy demonstration projects with the Tongnan District People's Government of Chongqing City.

Hydrogen Demonstration Project

.

.

In 2019, China's first waste-to-hydrogen project was launched in Wuhan, where hydrogen generated during waste incineration was collected and made into hydrogen oil

.

In September 2021, Dongfang Electric Group Dongfang Boiler Co.

, Ltd.

announced that it signed a letter of intent for cooperation in waste-to-energy coupled hydrogen production and hydrogen energy demonstration projects with the Tongnan District People's Government of Chongqing City.

Hydrogen Demonstration Project

.

Some people will also ask how to solve the problem of high cost of hydrogen production from waste

.

The industry generally believes that the cost of waste pyrolysis gasification hydrogen production is expected to drop below 20 yuan/kg, which is equivalent to the cost of natural gas hydrogen production technology, and has more added value - each ton of hydrogen will reduce 20 to 30 tons of CO2 emissions, Visible potential

.

Of course, if this is not the case, it will not attract the attention of countries such as the United States and Japan where the industrial chain of waste incineration power generation is quite mature

.

.

The industry generally believes that the cost of waste pyrolysis gasification hydrogen production is expected to drop below 20 yuan/kg, which is equivalent to the cost of natural gas hydrogen production technology, and has more added value - each ton of hydrogen will reduce 20 to 30 tons of CO2 emissions, Visible potential

.

Of course, if this is not the case, it will not attract the attention of countries such as the United States and Japan where the industrial chain of waste incineration power generation is quite mature

.

According to foreign media reports, the United States, Australia, Germany, Russia, and Japan all have plans to build waste-to-hydrogen plants.

The British government recently announced a £5 million funding plan for recyclable biomass hydrogen production and waste hydrogen production.

.

China's attempts in this field are not inferior at all.

In terms of commercial waste-to-hydrogen production, it is not known that it is possible to change lanes and overtake

.

The British government recently announced a £5 million funding plan for recyclable biomass hydrogen production and waste hydrogen production.

.

China's attempts in this field are not inferior at all.

In terms of commercial waste-to-hydrogen production, it is not known that it is possible to change lanes and overtake

.

Original title: Waste hydrogen production + carbon capture, the United States, Germany, Japan, Britain, etc.

are all in action, can China change lanes to overtake?

are all in action, can China change lanes to overtake?