-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

On October 17, Shandong Dongyue Group announced that the group's 10,000-ton polyvinylidene fluoride (PVDF) whole industry chain project Shenzhou Company's 10,000-ton PVDF, 20,000-ton VDF project and supporting chemical company's 25,000 tons of R142b, 5,000 tons of R143a and hydrogen fluoride automation improvement project, as well as long-chain supplementary chain strong chain 20,000 tons of TFE, R32 technical transformation 60,000 tons of R22 and other projects, have been completed and completed acceptance and fully entered the trial production stage

.

The group's newly put into production of 10,000 tons of PVDF project for power lithium-ion batteries, together with the group's existing PVDF production equipment, forms a PVDF resin production scale of 25,000 tons / year, covering all mainstream product grades, realizing comprehensive coverage of lithium batteries, photovoltaics, coatings, water treatment and other products, and becoming the main supplier of new energy enterprises such as CATL and BYD, effectively supporting the strong demand for new energy vehicles.

It will drive the green, healthy and sustainable development of the upstream and downstream industrial chain, and continue to consolidate Dongyue's position as a leading enterprise in the domestic market, which also strongly demonstrates the Group's determination and will

to break foreign monopoly and unswervingly move towards the field of new materials and new energy.

The successful commissioning of the new 10,000-ton PVDF project will bring great driving significance and demonstration significance

to the entire new energy industry chain of the group, especially for fluorine-containing polymer materials.

The 10,000-ton PVDF project has refreshed the "most"

of many Dongyue.

As the largest one-time investment project since the establishment of Huaxia Shenzhou New Materials Co.

, Ltd.

of Dongyue Group, the project construction adopts the most advanced process design, the optimal capacity of supporting equipment, from project design layout to one-key aggregation, to achieve comprehensive integration process, open up the whole process automation operation, the project automation rate has reached more than 90%, the aggregation capacity has increased by more than 35%, and the per capita production capacity has reached a new high

.

Through precise planning, the comprehensive energy saving reaches more than

20%.

Through process optimization, zero emission of polymer tail gas is realized, and at the same time, the "zero discharge" policy is actively implemented in the process water, supporting integrated water treatment facilities, and the automatic treatment and recycling of wastewater are realized, which has truly become a green and environmentally friendly scientific and technological innovation strategic project

.

Huaxia Shenzhou New Materials Co.

, Ltd.

has been deeply engaged in the field of PVDF materials for 14 years, and has now formed a series of innovative upgrades of production processes from raw material synthesis to production, with many national patents, and the products have reached the world's advanced level

in performance and life.

Its PVDF products have become the national manufacturing single champion products, ranking first in the country in production and sales for many consecutive years, with a domestic market share of more than

40%.

With the smooth operation of the PVDF whole industry chain project, the group's "fluorosilicon membrane hydrogen" high-tech industrial group has added another golden chain, which also provides strong support

for the key materials required for China's new energy vehicles to break the foreign monopoly.

It not only constitutes the main project of the group's new round of projects, but also plays an important role in strengthening the chain and supplementing the chain for the sustainable development of the whole fluorine silicon membrane hydrogen industry chain, and also makes the entire fluorosilicon membrane hydrogen industry chain and industrial group of the group enter a new stage of development and form new development advantages

.

China has become the world's largest consumer of fluorocarbon chemicals

It is understood that China's fluorocarbon chemicals have formed a relatively complete product system, and the total production capacity and output of major products will reach 2.

824 million tons and 1.

612 million tons in 2020, respectively, becoming the world's largest producer and consumer of

fluorocarbon chemicals.

In 2021, the total production capacity of China's main fluoropolymers, such as polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), perfluoroethylene propylene copolymer (FEP), fluororubber (FKM) and other products, will be 312,000 tons, an increase of 98.

2% over 2012, accounting for about 64.

9% of the global total production capacity, and the total output will be 258,000 tons, an increase of 249.

5%

over 2012.

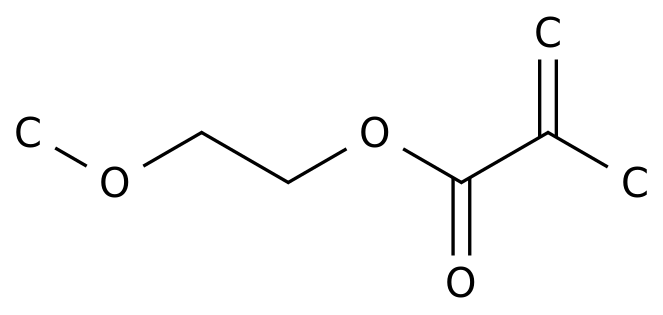

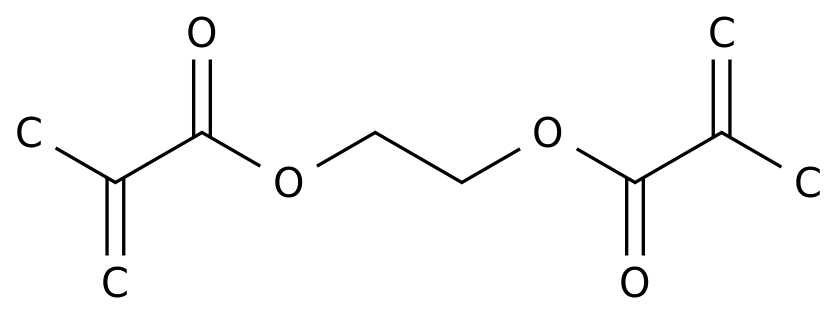

PVDF has excellent chemical stability, weather resistance and adhesion, and is widely used in fluorocarbon coatings, injection molding, lithium batteries, photovoltaic backsheets and water treatment and other fields

.

Among them, lithium battery is the fastest growing downstream field, PVDF is mainly used as a cathode binder, with the rapid development of new energy vehicles, energy storage and consumer electronics, demand continues to increase; At the same time, PVDF, as the main backplane film of photovoltaics, benefits from the rapid growth of the overall installed capacity of photovoltaics, and the demand has also increased

steadily.

It is estimated that the total demand for PVDF in 2021 will reach 60,000 tons, with reference to the average price of each category in 2021 of 195,000 yuan / ton, corresponding to a market size of 11.

7 billion yuan; By 2025, the total demand for PVDF will reach 134,000 tons, corresponding to a market size of 26.

1 billion yuan, with an average annual growth rate of 22%.

On the supply side, the current domestic PVDF effective production capacity is about 69,000 tons/year, the competition pattern is relatively scattered, in addition to Arkema and Dongyue have 1.

45 and 10,000 tons/year production capacity respectively, Solvay, Sanaifu, Ruyuan East Sunshine, Sinochem Blue Sky, Juhua, Funuolin, Lianchuang and other enterprises have a production capacity of 1,000 tons

.

In terms of new production capacity, although there are currently many capacity construction plans disclosed, some of them are still in the approval stage, and face barriers such as long construction certification cycles, technical difficulties, and upstream raw material restrictions, so it is difficult to significantly increase PVDF production capacity in the short and medium term, and it is expected that PVDF production capacity will reach 8.

3, 11.

9, 16.

2 and 179,000 tons from 2022 to 2025 (excluding production capacity that has not yet received EIA).

Juhua, Dongyue, Funuolin and other enterprises have expanded their production on a large scale, and all have R142b support

.