-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

In recent years, with the continuous tightening of carbon emission regulations and concerns about the energy crisis, the electrification of the automotive industry has continued to accelerate and deepen, and has become a globally recognized development direction

.

1.

The general trend has come, and the "electrification" of automobiles is surging

The general trend has come, the "electrification" of automobiles is surging

In recent years, with the continuous tightening of carbon emission regulations and concerns about the energy crisis, the electrification of the automotive industry has continued to accelerate and deepen, and has become a globally recognized development direction

.

As the power system gradually changes from the internal combustion engine to the electric drive, the electrified vehicle presents different requirements and challenges to the engineering plastics for vehicles

.

Unlike traditional internal combustion engine systems, electric powertrains typically operate at high voltages of hundreds of volts, with currents as high as hundreds of amps, and some companies are striving to increase voltages to 1000V and even higher in pursuit of higher charging speeds and efficiencies.

high

.

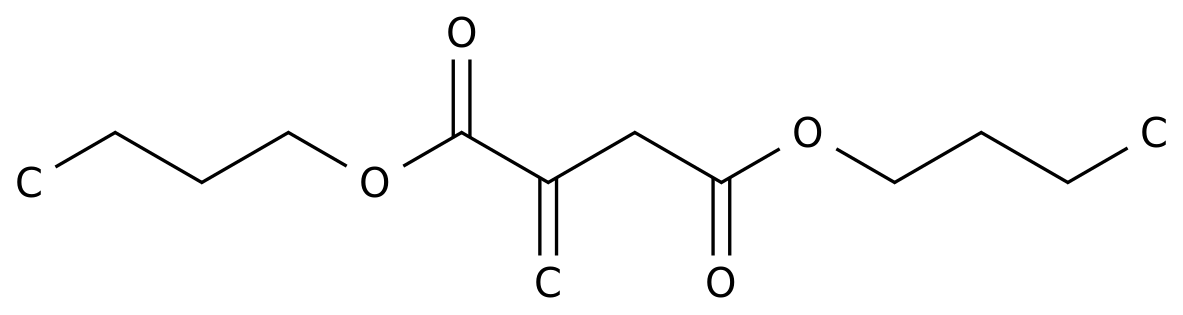

(Image source DSM)

2.

DSM follows the trend and releases a white paper on next-generation materials

DSM follows the trend and releases a white paper on next-generation materials

Faced with the stringent requirements of electric vehicle powertrains, DSM has introduced a range of polyamides PA6, 46, 66, 666, 410, 410, aromatic polyamides PA 4T (PPA) and PA 4T (FoTii Ace), and PPS , PBT, PET and polyester-based thermoplastic elastomers (TPC) and other engineering plastic products

.

■ PA 4T (FoTii Ace): The glass transition temperature is 160oC.

In applications up to 150°C continuous use temperature, no thermal stabilizer is used to ensure the mechanical properties of polyamide, thereby avoiding core automotive components such as sensors and connectors.

Galvanic corrosion due to additives

.

■ Akulon PA66 and ForTii PPA:CTI are rated over 700V and 850V respectively, which can help design engineers to achieve more functions or design more electronic components in a small space, and also avoid the use of good packaging caused by cost

.

■ Xytron PPS: has good temperature and aging resistance, suitable for peak operating temperature over 200 ℃, and can be used in harsh environments containing corrosive chemicals, oils or other chemical agents

.

(Image source DSM)

*DSM's cumulative sales in 2019 were EUR 9.

01 billion, an increase of 2% year-on-year, net profit was EUR 764 million, and adjusted net profit was EUR 830 million, an increase of 8% year-on-year

.

3.

Enterprises are competing for layout, and no one is willing to lag behind

Enterprises are competing for layout, and no one is willing to lag behind

DuPont: Based on the development trend of automobile electrification, it has launched diversified solutions, including BETAMATETM and BETAFORCETM structural adhesives, Zytel nylon resin, Nomex? fiber products,

etc.

At present, DuPont has carried out in-depth cooperation with industry chain partners NIO and Ningde Times New Energy Technology Co.

,

Ltd.

BASF: Launched Ultramid flame retardant products, including C3U, A2X2G5, A3X2G5, A3X2G7, A3X2G10, B3UG4 and KR4365G5, which can be applied to electrical components that require high fire safety and tracking resistance

.

LANXESS: Develops tailor-made PA and PBT components for lithium batteries, electric powertrains and charging infrastructure

.

It launched Durethan BKV45FN04, with 45% by weight glass fiber reinforcement

.

Halogen free flame retardant P6 passed UL 94 flame retardant test with best classification V-0 (0.

4mm) and tracking resistance at high voltage for components such as battery frames, end plates and high voltage connectors

.

Toray: Launched solutions for new energy battery modules, including PA battery end plates, PBT battery separators, battery housings, PPS power modules and other materials in the field of new energy vehicles

.

Polyplastics: Introduced DURANEX (R) PBT CG7030 to provide low water absorption and high tracking performance for high voltage components such as PCUs, ensuring high reliability for high voltage components with insufficient creepage distances

.

DURAFIDE (R) PPS 6150T73, provides high thermal shock resistance, strong dimensional stability and excellent thermal and chemical resistance for metal insert molding applications in electric vehicles

.

Kingfa Technology: For charging piles and battery modules, it has launched a series of material solutions such as flame-retardant PA or PBT, flame-retardant PPE and flame-retardant PP

.

CGN Juner: In terms of new energy vehicle charging pile materials and battery plastics, it has launched flame retardant PC/ABS alloys, flame retardant reinforced nylon, PBT, and flame retardant reinforced PPO

.