-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

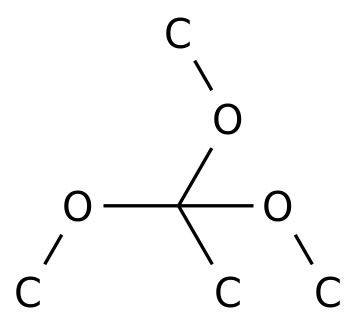

Diphenyl carbonate (DPC) is an important intermediate chemical in the production of plastics, synthetic rubber, and other chemical products.

The production process of DPC involves several steps, which are carefully coordinated to ensure high yields and quality of the final product.

- Phenol production: The first step in the production of DPC is the production of phenol, which is a primary raw material.

Phenol is produced through the hydroxylation of benzene in the presence of a catalyst, such as sodium hydroxide or hydrogen peroxide. - Carbon disulfide production: Carbon disulfide is another important raw material used in the production of DPC.

Carbon disulfide is produced by treating sulfur with carbon in the presence of a solvent, such as benzene or toluene. - Reaction of phenol and carbon disulfide: The next step in the production of DPC is the reaction of phenol and carbon disulfide in the presence of a condensation agent, such as sodium hydroxide or sodium sulfate.

The reaction is exothermic and generates a significant amount of heat, which must be carefully controlled to avoid any hazards. - Recovery of DPC: The resulting product of the reaction is a mixture of diphenyl carbonate and other byproducts, such as hydroxylated bisphenol.

To obtain pure DPC, the mixture is distilled, and the DPC is separated from the other components. - Purification of DPC: After distillation, the DPC is further purified through a series of chemical reactions and filtration steps to remove any remaining impurities.

- Packaging and shipping: The final step in the production process is the packaging and shipping of the pure DPC to the customer.

The DPC is typically packaged in drums or tankers and shipped by truck or rail.

Overall, the production process of DPC involves several steps that require careful coordination to ensure high yields and quality of the final product.

The process also requires the use of various chemicals and equipment, which must be carefully managed to minimize any potential hazards.

With proper management and control, the production of DPC can be a safe and efficient process that provides high-quality intermediate chemicals for a range of applications in the chemical industry.