-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Key points guide

Key points guide1.

Sidel launched the industry's first "opaque light-blocking PET recycling solution from bottle to bottle";

2.

Veolia's "Carbon Footprint of Inspection Materials" shows that: plastic carbon emissions are lower than paper, glass, stainless steel and aluminum;

3.

Sinopec launched biaxially oriented polyethylene (BOPE) special materials and film products;

4.

Dow launched a line of post-consumer recycled (PCR) resins to meet brand owners’ growing demand for more recycled plastics

.

01Sidel launched the industry's first "opaque light-blocking PET bottle-to-bottle recycling solution"

01Sidel launched the industry's first "opaque light-blocking PET bottle-to-bottle recycling solution"Sidel and industry partners have jointly developed non-transparent light-blocking PET bottle-to-bottle recycling technology, becoming the first expert in the industry to achieve 100% bottle-to-bottle recycling of white opaque light-blocking PET bottles, technically proving the use of recycled materials It is feasible to manufacture opaque light-blocking PET bottles without reducing the production speed, without affecting the color, characteristics, function,

etc.

After the white opaque light-blocking PET bottle is recycled, it can be reused to manufacture the white opaque light-blocking PET bottle, and can also be used for higher value-added purposes, which greatly promotes the development of circular economy

.

02.

Veolia's "Carbon Footprint of Inspection Materials" shows that plastic carbon emissions are lower than those of paper, glass, stainless steel and aluminum

Veolia, the world's largest environmental protection group, released its "Carbon Footprint of Testing Materials" report at Imperial College London a few days ago

.

Most case assessments show that packaging in materials such as paper, glass, stainless steel and aluminium has a higher carbon footprint than plastic throughout its life cycle, the report said

.

Taking plastic bottles as an example, Veolia claims that replacing plastic bottles with glass bottles on a global scale will generate additional carbon emissions equivalent to those emitted by 22 large coal-fired power plants

.

According to Veolia, the key to minimising environmental footprint and carbon emissions is the reduction, reuse and optimization of recyclable recycled materials, as well as effective waste management at the end of the packaging's life

.

Plastics can play a key role in creating a zero-carbon world, provided they are produced, used and recycled responsibly

.

03.

Sinopec launched biaxially oriented polyethylene (BOPE) special materials and film products

On July 7, the biaxially oriented polyethylene (BOPE) special material and film products independently developed by the Beijing Institute of Chemical Industry, a subsidiary of Sinopec, have been identified to reach the world's leading level in various performance indicators, filling the domestic gap

.

BOPE film is widely used in rice vacuum packaging, quick-frozen food packaging, beverage transparent flexible packaging and other fields.

Compared with traditional polyethylene film, it can reduce material usage by 30%, which is economical and environmentally friendly

.

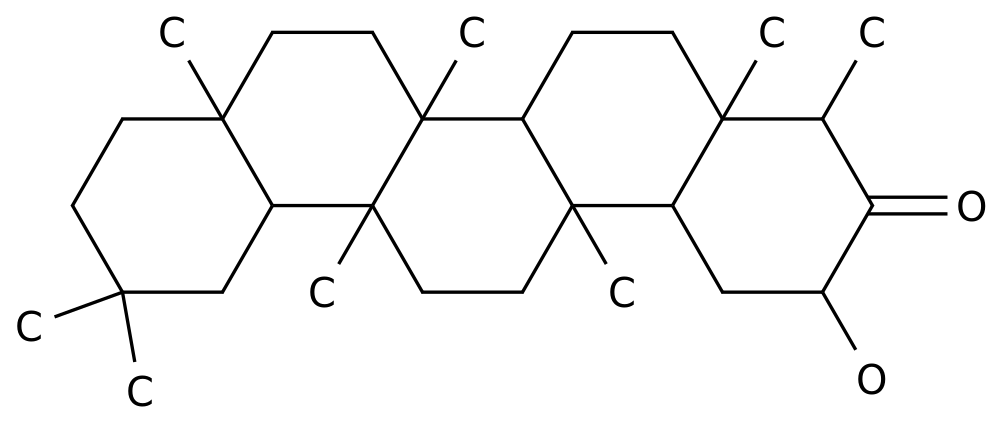

Figure: Biaxially oriented polyethylene BOPE raw material

BOPE film is a high-performance film product made of polyethylene resin with special molecular structure design through a special biaxial stretching process

.

Compared with traditional polyethylene film, BOPE film not only has better toughness, stiffness, puncture resistance and low temperature impact resistance, but also better transparency, printing performance and higher production efficiency

.

Packaging with BOPE film can effectively reduce the thickness of plastic packaging and reduce the use of packaging materials by about 30%

.

The "BOPE+CPE" all-polyethylene packaging products made of cast polyethylene (CPE) special materials and films that also own Sinopec's independent intellectual property rights also have significant recyclability and recycling advantages, in line with the national development strategy of circular economy And the "14th Five-Year Plan" requirements for the recyclability of plastic products to meet the market demand for green packaging

.

Figure: BOPE film with excellent optical properties

04.

Dow launches post-consumer recycled (PCR) resin line to meet growing demand from brand owners for more recycled plastics

On June 17, Dow announced that it has developed and commercialized a new material XUS 60921.

01 for post-consumer recycled (PCR) resins that can be used 100% in the middle layer of heat shrinkable films, which will be produced globally

.

Recycled plastic resins are designed to harness the resources of old soft and rigid plastic packaging to create new packaging materials, while keeping waste out of the environment

.

The offering underscores Dow's comprehensive strategy to develop a circular economy for plastics by focusing on integrating recycled content into products

.

Already available in Asia and Europe, Dow's new PCR resins offer brands and consumers comparable performance to virgin resin packaging, while reducing carbon footprints by 20-30%, depending on the product and application offered

.

It will also give a new lifespan to plastic that would otherwise be wasted

.

Image credit: Dow

Dow's new PCR resin will help ensure safe product delivery while reducing end-waste in our environment of plastic waste

.

It can also be used in rigid packaging to make bottles for the home care market

.

The new materials directly support Dow’s recently announced sustainability goals, which include reducing waste by enabling millions of tons of plastic to be collected, reused or recycled by 2030 through our direct actions and partnerships, and Commitment to reducing waste by reducing its net carbon emissions by 5 million tons per year

.

1 million tonnes by 2030 and carbon neutral by 2050

.