-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Project 1 On November 9, 2017, Nanshan Group and American Ethane Corporation (AEC) participated in the historic summit of Chinese and American leaders and signed a large-scale ethane import cooperation agreement

.

This is China's first contract to import US ethane

.

The prelude to the entry of light hydrocarbons into the Chinese market has substantially kicked off! According to John Houghtaling, CEO of American Ethane Company, the signing of a 20-year long-term CIF (CIF) contract between American Ethane Company and Nanshan Group

.

According to the contract, the American Ethane Company will supply 2.

6 million tons of ethane to Nanshan Group every year and participate in the investment in the 2 million tons of ethane to ethylene project planned by Nanshan Group

.

Project 2 In late November 2017, Jiangsu Xinpu Chemical and Ineos Group signed a long-term agreement under which Ineos will supply ethane produced in the United States to Xinpu Chemical Cracker

.

On January 12, 2018, the propylene distillation tower, a key equipment of the 1.

1 million tons/young hydrocarbon comprehensive utilization project (LHUP) of Xinpu Olefin Company, was successfully installed

.

The project is located in China Fine Chemicals (Taixing) Development Park.

The main products include 650,000 tons/year polymer grade ethylene, 122,000 tons/year polymer grade propylene and hydrogen, methane, mixed carbon four, pyrolysis gasoline and fuel oil, etc.

The total investment of the project 5.

5 billion yuan

.

Project 3 On the morning of December 20, 2017, Juneng Heavy Industry Group and the US ethane company Jinzhou 2 million tons of ethane to ethylene project signed a contract in Jinzhou

.

On September 30, 2017, Juneng Heavy Industry Group's 2 million tons of ethane cracking to ethylene project successfully settled in Jinzhou

.

As a major investment attraction project in Jinzhou City, this project is expected to have a total investment of RMB 26.

1 billion and a construction period of 36 months

.

It is estimated that the annual value will exceed 19 billion yuan after the completion of the project, and 3,500 people can be employed

.

According to the contract signed between Joneng Heavy Industries and the American Ethane Company, the American Ethane Company will supply 2.

6 million tons of ethane to the project each year and participate in the investment in the planned 2 million tons of ethane to ethylene project in Jinzhou City.

.

Project 4 On February 1, 2018, Yangmei Group Qingdao Hengyuan Chemical Co.

, Ltd.

signed an ethane supply agreement with American Ethane Company.

Yangmei Group plans to build a 2 million tons/year ethane comprehensive utilization project in Dongjiakou, Qingdao

.

Dongjiakou Lingang New Chemical Material Park currently has 400,000 tons/year PVC, 500,000 tons/year styrene production equipment, 400,000 tons/year VCM projects under construction, etc.

, which can consume more than 500,000 tons of ethylene per year

.

The project has an annual output of 1.

5 million tons of ethylene.

In addition to downstream users such as PVC and styrene in the park, new polyolefin materials such as FDPE, CPE special material polyethylene, and ultra-high molecular weight polyethylene will be built

.

From November 2017 to February 2018, the U.

S.

ethane company has signed three large export orders for ethane, with a total supply of 7.

2 million tons of ethane per year

.

The shale gas revolution has brought abundant and cheap ethane resources to the United States, and China is the world's largest consumer market

.

China imported 11.

794 million tons of polyethylene in 2017, an increase of 18.

6% year-on-year.

In 2017, China's ethylene glycol imports exceeded 8 million, and ethylene monomer is still scarce in China

.

The ethane carrier EthaneCrystal, Samsung Heavy Industries, belongs to Reliance Industries Ltd.

The ethane carrier EthaneCrystal, Samsung Heavy Industries, belongs to Reliance Industries Ltd.

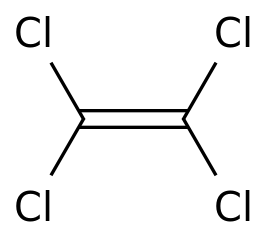

Compared with the traditional process route of naphtha cracking to ethylene, the ethane cracking ethylene process project has low investment, The raw material cost is low, the ethylene yield is high, and the ethylene purity is high, and the product route is single

.

International crude oil prices are showing a gradual upward trend, and the cost advantage of the alkane route will become more prominent

.

Among the downstream derivatives of ethylene, polyethylene and ethylene glycol are highly dependent on imports, and the market demand remains strong

.

At present, the domestic ethylene equivalent self-sufficiency rate is only 52.

5%, and the equivalent gap is as high as 19.

65 million tons.

It is expected that the domestic equivalent gap will still be more than 16 million tons by 2025, and the ethylene market still has huge room for development

.

The ethylene industry chain has high profitability

.

1 One of the key points for domestic enterprises in the operation of ethane cracking projects is stable material supply.

In addition, storage and logistics requirements are high and infrastructure investment is large

.

Ethane is mainly transported by pipeline and ship.

From the coast of the Gulf of Mexico in the United States to the Yangtze River port in China, large cryogenic vessels are required, and the storage of the terminal needs to be equipped with a refrigerated tank area

.

Both the U.

S.

Ethane Company and the domestic Xinpu Chemical are building large-scale transportation ships for ethane transportation

.

From the current point of view, ethane cracking ethylene is full of prospects.

With the commissioning of some devices in 2019, it will ease the pressure on domestic ethylene imports

.

The import contract with the US ethane company is a long-term contract, which can relatively guarantee the supply of raw materials

.

Coastal chemical companies have the advantage of ports and reduce the cost of land transportation

.

There is a large supply gap in ethylene in China

.

The ethane-to-ethylene process has a single product.

Enterprises need to scientifically and rationally plan downstream supporting industries, and fully consider the synergies of surrounding industries to enhance project operation capabilities

.

.

This is China's first contract to import US ethane

.

The prelude to the entry of light hydrocarbons into the Chinese market has substantially kicked off! According to John Houghtaling, CEO of American Ethane Company, the signing of a 20-year long-term CIF (CIF) contract between American Ethane Company and Nanshan Group

.

According to the contract, the American Ethane Company will supply 2.

6 million tons of ethane to Nanshan Group every year and participate in the investment in the 2 million tons of ethane to ethylene project planned by Nanshan Group

.

Project 2 In late November 2017, Jiangsu Xinpu Chemical and Ineos Group signed a long-term agreement under which Ineos will supply ethane produced in the United States to Xinpu Chemical Cracker

.

On January 12, 2018, the propylene distillation tower, a key equipment of the 1.

1 million tons/young hydrocarbon comprehensive utilization project (LHUP) of Xinpu Olefin Company, was successfully installed

.

The project is located in China Fine Chemicals (Taixing) Development Park.

The main products include 650,000 tons/year polymer grade ethylene, 122,000 tons/year polymer grade propylene and hydrogen, methane, mixed carbon four, pyrolysis gasoline and fuel oil, etc.

The total investment of the project 5.

5 billion yuan

.

Project 3 On the morning of December 20, 2017, Juneng Heavy Industry Group and the US ethane company Jinzhou 2 million tons of ethane to ethylene project signed a contract in Jinzhou

.

On September 30, 2017, Juneng Heavy Industry Group's 2 million tons of ethane cracking to ethylene project successfully settled in Jinzhou

.

As a major investment attraction project in Jinzhou City, this project is expected to have a total investment of RMB 26.

1 billion and a construction period of 36 months

.

It is estimated that the annual value will exceed 19 billion yuan after the completion of the project, and 3,500 people can be employed

.

According to the contract signed between Joneng Heavy Industries and the American Ethane Company, the American Ethane Company will supply 2.

6 million tons of ethane to the project each year and participate in the investment in the planned 2 million tons of ethane to ethylene project in Jinzhou City.

.

Project 4 On February 1, 2018, Yangmei Group Qingdao Hengyuan Chemical Co.

, Ltd.

signed an ethane supply agreement with American Ethane Company.

Yangmei Group plans to build a 2 million tons/year ethane comprehensive utilization project in Dongjiakou, Qingdao

.

Dongjiakou Lingang New Chemical Material Park currently has 400,000 tons/year PVC, 500,000 tons/year styrene production equipment, 400,000 tons/year VCM projects under construction, etc.

, which can consume more than 500,000 tons of ethylene per year

.

The project has an annual output of 1.

5 million tons of ethylene.

In addition to downstream users such as PVC and styrene in the park, new polyolefin materials such as FDPE, CPE special material polyethylene, and ultra-high molecular weight polyethylene will be built

.

From November 2017 to February 2018, the U.

S.

ethane company has signed three large export orders for ethane, with a total supply of 7.

2 million tons of ethane per year

.

The shale gas revolution has brought abundant and cheap ethane resources to the United States, and China is the world's largest consumer market

.

China imported 11.

794 million tons of polyethylene in 2017, an increase of 18.

6% year-on-year.

In 2017, China's ethylene glycol imports exceeded 8 million, and ethylene monomer is still scarce in China

.

The ethane carrier EthaneCrystal, Samsung Heavy Industries, belongs to Reliance Industries Ltd.

The ethane carrier EthaneCrystal, Samsung Heavy Industries, belongs to Reliance Industries Ltd.

Compared with the traditional process route of naphtha cracking to ethylene, the ethane cracking ethylene process project has low investment, The raw material cost is low, the ethylene yield is high, and the ethylene purity is high, and the product route is single

.

International crude oil prices are showing a gradual upward trend, and the cost advantage of the alkane route will become more prominent

.

Among the downstream derivatives of ethylene, polyethylene and ethylene glycol are highly dependent on imports, and the market demand remains strong

.

At present, the domestic ethylene equivalent self-sufficiency rate is only 52.

5%, and the equivalent gap is as high as 19.

65 million tons.

It is expected that the domestic equivalent gap will still be more than 16 million tons by 2025, and the ethylene market still has huge room for development

.

The ethylene industry chain has high profitability

.

1 One of the key points for domestic enterprises in the operation of ethane cracking projects is stable material supply.

In addition, storage and logistics requirements are high and infrastructure investment is large

.

Ethane is mainly transported by pipeline and ship.

From the coast of the Gulf of Mexico in the United States to the Yangtze River port in China, large cryogenic vessels are required, and the storage of the terminal needs to be equipped with a refrigerated tank area

.

Both the U.

S.

Ethane Company and the domestic Xinpu Chemical are building large-scale transportation ships for ethane transportation

.

From the current point of view, ethane cracking ethylene is full of prospects.

With the commissioning of some devices in 2019, it will ease the pressure on domestic ethylene imports

.

The import contract with the US ethane company is a long-term contract, which can relatively guarantee the supply of raw materials

.

Coastal chemical companies have the advantage of ports and reduce the cost of land transportation

.

There is a large supply gap in ethylene in China

.

The ethane-to-ethylene process has a single product.

Enterprises need to scientifically and rationally plan downstream supporting industries, and fully consider the synergies of surrounding industries to enhance project operation capabilities

.