-

The Instruction of Xylene

Time of Update: 2023-04-30

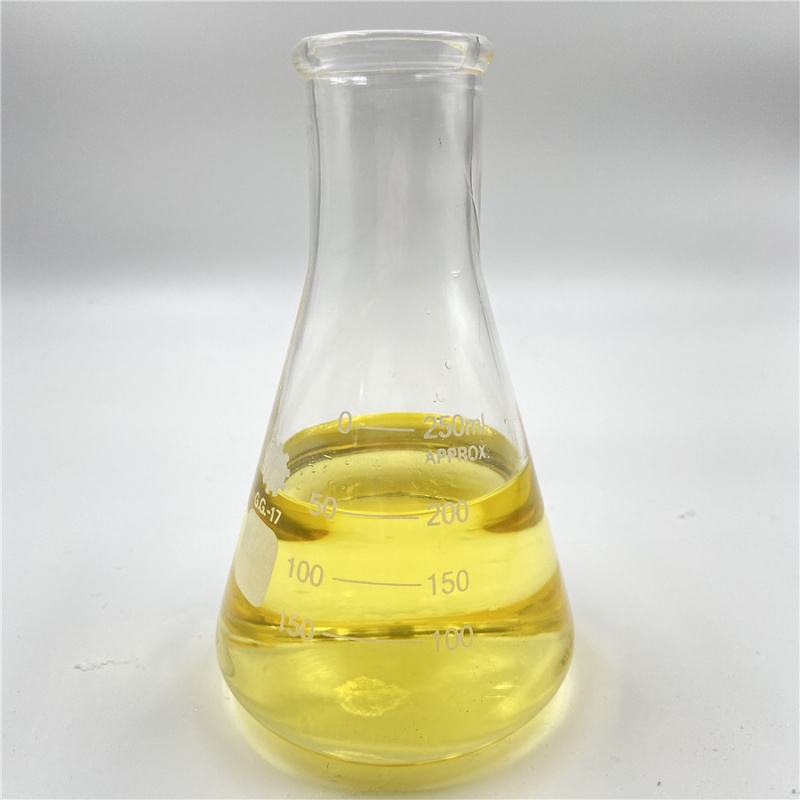

The use of xylene in the chemical industry requires careful handling and proper storage.

The use of xylene in the chemical industry requires careful handling and proper storage.

The use of xylene in the chemical industry requires careful handling and proper storage.

-

The Safety of Xylene

Time of Update: 2023-04-30

It is important to handle and store xylene properly, use appropriate personal protective equipment, and follow proper safety procedures when working with the substance.

It is important to handle and store xylene properly, use appropriate personal protective equipment, and follow proper safety procedures when working with the substance.

-

The Upstream and Downstream products of Xylene

Time of Update: 2023-04-30

Processes The production of xylene and its downstream products involves a variety of processes, including distillation, fractionation, catalytic cracking, and chemical reactions.

ProcessesThe production of xylene and its downstream products involves a variety of processes, including distillation, fractionation, catalytic cracking, and chemical reactions.

-

The Production Process of 1,3,5-Tris(bromomethyl)-2,4,6-trimethylbenzene

Time of Update: 2023-04-30

In conclusion, the production process of tris bromide involves several stages, including raw material preparation, hydrolysis, bromination, purification, characterization, and packaging.

In conclusion, the production process of tris bromide involves several stages, including raw material preparation, hydrolysis, bromination, purification, characterization, and packaging.

-

The Upstream and Downstream products of 1,3,5-Tris(bromomethyl)-2,4,6-trimethylbenzene

Time of Update: 2023-04-30

This process involves the addition of bromine atoms to the TBB molecule, resulting in the formation of PBDEs. Another upstream product derived from TBB is tetrachlorobenzene (TCB).

-

The Applications of 1-Nitronaphthalene

Time of Update: 2023-04-30

In addition to its use as a precursor to other aromatic compounds and as a catalyst, 1-nitronaphthalene has a number of other applications in the chemical industry.

-

The Applications of 1,3,5-Tris(bromomethyl)-2,4,6-trimethylbenzene

Time of Update: 2023-04-30

In conclusion, Tribromomethylbenzene is an important compound in the chemical industry, with a wide range of applications in the production of dyes, pigments, pharmaceuticals, plastics, and elastomers.

-

The Instruction of 1,3,5-Tris(bromomethyl)-2,4,6-trimethylbenzene

Time of Update: 2023-04-30

The manufacturing process of BrBTB involves several steps, including the reaction of 1,3,5-trimethylbenzene with hydrogen bromide and the subsequent treatment with a base.

The manufacturing process of BrBTB involves several steps, including the reaction of 1,3,5-trimethylbenzene with hydrogen bromide and the subsequent treatment with a base.

-

The Safety of 1-Nitronaphthalene

Time of Update: 2023-04-30

To minimize the risk of these hazards, it is important to follow proper safety procedures when handling 1-nitronaphthalene.

To minimize the risk of these hazards, it is important to follow proper safety procedures when handling 1-nitronaphthalene.

-

The Applications of Xylene

Time of Update: 2023-04-30

Xylene is also used in the production of adhesives, where it helps in dissolving the resins and other components to create a uniform solution.

Xylene is also used in the production of adhesives, where it helps in dissolving the resins and other components to create a uniform solution.

![Aluminum, [(2E)-2-butenedioato(2-)-κO1]hydroxy- Al-Fum](https://file.echemi.com/fileManage/upload/goodpicture/20230919/ibrutinib-high-quality_b20230919163357076.jpg)

![2,4,6-Tris[3-(diphenylphosphinyl)phenyl]-1,3,5-triazine CAS: 1646906-26-4](https://file.echemi.com/fileManage/upload/goodpicture/20230912/factory-price-sodium-benzotriazolyl-butylphenol-sulfonate_b20230912165059719.png)