-

Dry! Application and construction of high temperature resistant silicone coatings

Time of Update: 2022-12-04

(9) Curing according to the drying conditions required by silicone coating products to ensure the quality of the paint film.

(9) Curing according to the drying conditions required by silicone coating products to ensure the quality of the paint film.

-

Water-based ink formulation and process (characteristics of water-based inks)

Time of Update: 2022-11-01

The composition of water-based inksWater-based ink is mainly composed of main agent and auxiliary, of which the main agent mainly has pigments to give the ink color; The connecting material, also known as resin, gives the ink a certain fluidity, so that the ink has suitable transfer properties when printing on the machine.

-

How can antioxidants and light stabilizers improve the weather resistance of powder coatings?

Time of Update: 2022-10-14

The test results sorted by the order of color of the coating film from second increment to optimization can be seen:1, the basic formula 1 has serious loss of light, although the pigment heat resistance is better, but after the film formation of the discoloration, the analysis believes that the pigment is oxidized at high temperature, under the action of oxygen some groups in the pigment react.

-

What you don't know about the formulation design of car brake pads with low temperature curing powder coatings

Time of Update: 2022-09-20

epilogueBecause the brake pad will rub and heat when working, the temperature of the brake pad will rise sharply in a short period of time, so the coating must have good heat dissipation performance, heat resistance, moisture and heat resistance, and the use environment of the brake pad requires that the neutral salt spray performance of the coating is also relatively high.

-

What are the six commonly used additives for UV coatings?

Time of Update: 2022-08-20

Commonly used additives for UV coatings include defoamer, leveling agent, wetting and dispersing agent, adhesion promoter, matting agent, polymerization inhibitor, etc.

Commonly used additives for UV coatings include defoamer, leveling agent, wetting and dispersing agent, adhesion promoter, matting agent, polymerization inhibitor, etc.

-

Win-win cooperation--Zhongkeyu weather gel special additives sincerely recruit provincial and municipal agents

Time of Update: 2022-08-11

With extremely low bulk density and nano-grid structure, the thermal conductivity of aerogel is lower than that of static air at room temperature, making it the most perfect thermal insulation material so far to the industrial and civil fields .

-

Special solutions for high-performance adhesives

Time of Update: 2022-08-11

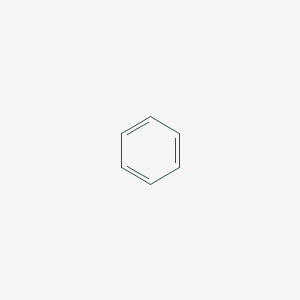

Figure 2 Chemical versatility of SH chain-terminated polysulfide polymers Polysulfides in epoxy resin systems Although thiols can react with isocyanates, dienes, or oxidizing agents, in this paper we mainly focus on epoxides as reactive materials .

-

High hardness, good gloss, excellent leveling!

Time of Update: 2022-08-11

With the promotion and the influence of the downstream market on water-based coatings, the demand for water-based acrylic emulsions maintains a rapid upward trend, and the industry has more and more room for growth Dr. Zhang, head of the R&D Department of Dana Chemical, said that with the improvement of consumers' health and environmental protection awareness in China, consumers are paying more attention to the possible harmful substances in products.

-

Understand the application advantages and characteristics of pigments, binders and additives in inks

Time of Update: 2022-08-10

Colorants are divided into two types, one is pigment, which is suspended and dispersed in the ink in the form of particles, and the other is dye, which is dispersed in the ink in a molecular state.

-

The annual revenue is 1.64 billion yuan, and the coating project with an annual output of 100,000 tons has settled in Chuzhou!

Time of Update: 2022-05-11

3 million yuan to build a new annual output of 100,000 tons of water-based industrial coatings, water-based nano-ink colorants, resins, high-solid coatings, thinners, curing agents, and additives.

Its main business scope is water-based industrial coatings, high-solid coatings, water-based nano-ink colorants, coating supporting products (thinners, curing agents), resins and auxiliary products.