-

The Production Process of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

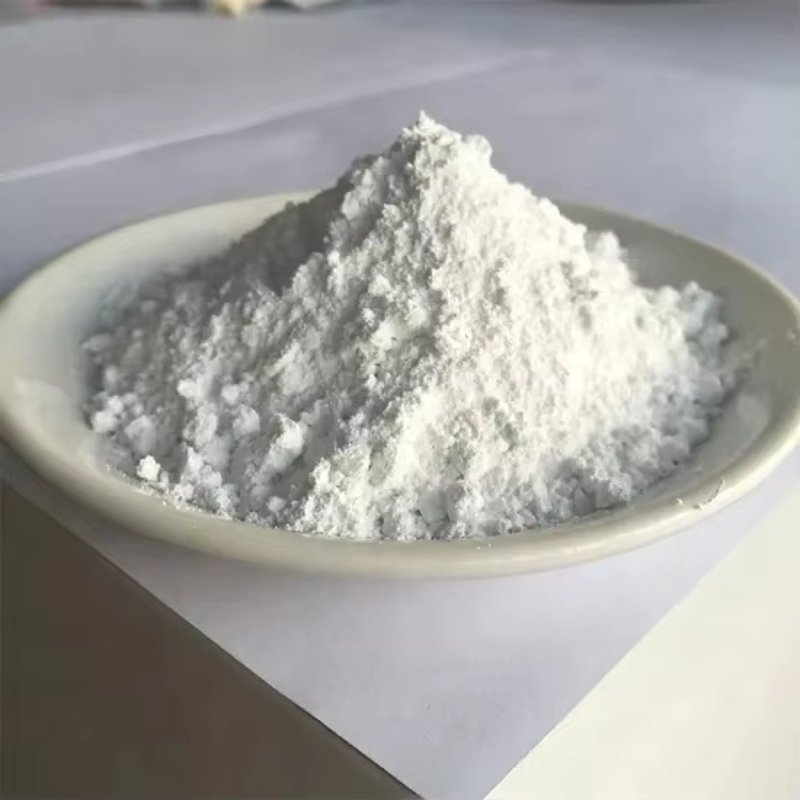

In conclusion, the production process of wollastonite involves several steps, including mining and crushing, grinding and classification, calcination, roasting, and packaging.

In conclusion, the production process of wollastonite involves several steps, including mining and crushing, grinding and classification, calcination, roasting, and packaging.

-

The Applications of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

Other applications of wollastonite include its use as a catalyst in chemical reactions, as a source of calcium in agriculture, and as a construction material in the production of cement and concrete.

-

The Upstream and Downstream products of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

Wollastonite is used in a variety of applications in the chemical industry, including as a filler in the production of paint and coatings, as a flame retardant in plastics and textiles, and as a catalyst in the production of chemicals.

-

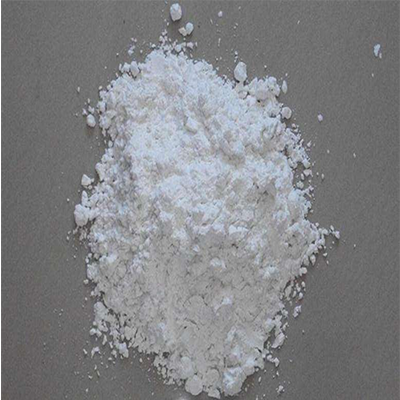

The Instruction of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

Wollastonite has a number of industrial uses, including as a filler in rubber and plastics, as a construction material, and as a source of calcium in fertilizers and soil conditioners.

-

The Synthetic Routes of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

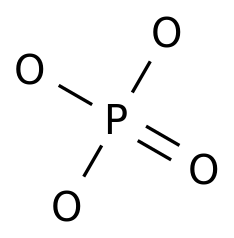

There are several synthetic routes for producing wollastonite, including the following: The fluidized bed process: This process involves the reaction of calcium oxide and silicon oxide in a fluidized bed reactor.

-

The Safety of Wollastonite (Ca(SiO3))

Time of Update: 2023-05-01

Whether you are looking for a safe and effective fire retardant, a high-purity ingredient for chemical production, or a reliable thermal stabilizer, wollastonite is an excellent choice.

-

The Production Process of Zirconium sulfate

Time of Update: 2023-04-30

The production process of zirconium sulfate involves several steps, including the preparation of the raw materials, the actual synthesis of the compound, and the purification and packaging of the final product.

-

The Safety of Disodium monofluorophosphate

Time of Update: 2023-04-30

Despite these concerns, DFP is still widely used in the chemical industry, and it is important for workers in this field to take proper precautions to protect themselves and the environment from the potential hazards associated with this chemical.

-

The Applications of Sodium metasilicate pentahydrate

Time of Update: 2023-04-30

It is a sodium salt of silicic acid and is often used as a catalyst, a flux, a neutralizing agent, and a viscosity-increasing agent in various chemical reactions and processes.

-

The Applications of Sodium monofluorophosphate

Time of Update: 2023-04-30

MFP is used as a catalyst in the production of refrigerants, helping to speed up the reaction and improve the efficiency of the process.

MFP is used as a catalyst in the production of refrigerants, helping to speed up the reaction and improve the efficiency of the process.

![Sodium Sulfate [Na2SO4] CAS Number 7757-82-6 99+% ACS Grade Powder](https://file.echemi.com/fileManage/upload/goodpicture/20250806/sodium-sulfate-na2so4-cas-number-7757-82-6-99-acs-grade-powder_b20250806175748042.png)