-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Wollastonite, also known as calcium silicate, is a widely used material in the chemical industry.

It is a synthetic mineral that is commonly used as a filler in a variety of industrial applications, including the production of paints, coatings, and adhesives.

There are several synthetic routes for producing wollastonite, including the following:

- The fluidized bed process: This process involves the reaction of calcium oxide and silicon oxide in a fluidized bed reactor.

The reaction produces wollastonite, which is then collected and ground to the desired particle size. - The hydrothermal process: This process involves the reaction of calcium oxide and silicon oxide in aqueous solution.

The reaction produces wollastonite, which is then collected and ground to the desired particle size. - The solid-state reaction process: This process involves the reaction of calcium oxide and silicon oxide in a solid-state reaction.

The reaction produces wollastonite, which is then collected and ground to the desired particle size.

All of these synthetic routes have their own advantages and disadvantages, and the choice of route will depend on the specific requirements of the application.

For example, the fluidized bed process may be preferred for its ability to produce wollastonite with a very specific particle size distribution, while the hydrothermal process may be preferred for its ability to produce high-purity wollastonite.

Once produced, the wollastonite is typically ground to the desired particle size and may be further processed to remove any impurities.

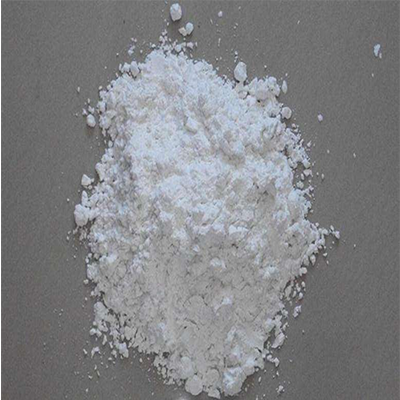

The resulting product is a white, odorless, and tasteless powder that is widely used in the chemical industry.

In conclusion, the synthetic routes of wollastonite are numerous, and choosing the right one will depend on the specific requirements of the application.

However, once produced, the wollastonite is a versatile and valuable material that is widely used in a variety of industrial applications.