-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

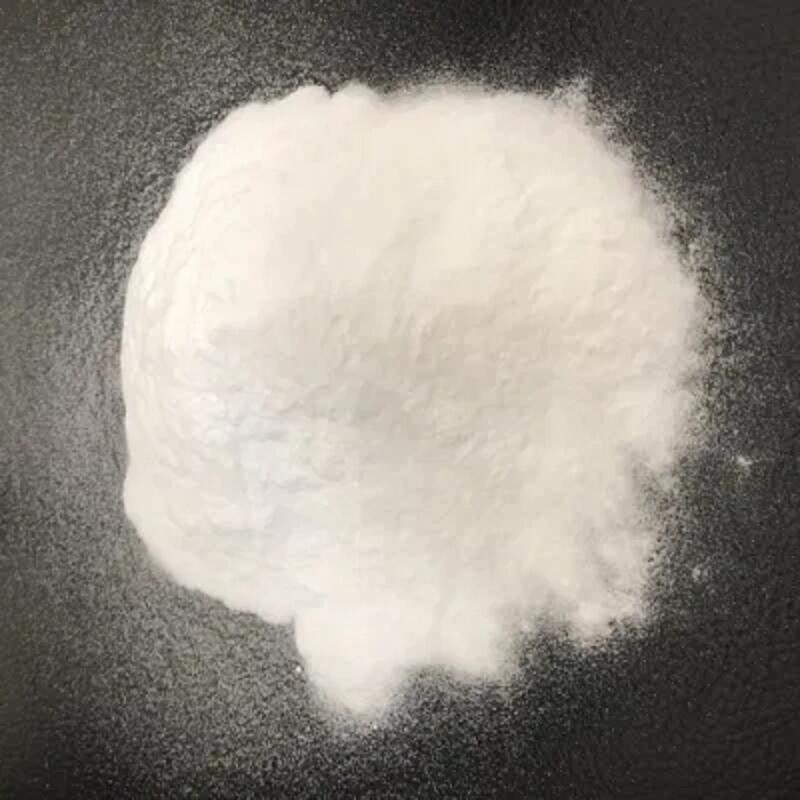

Antimony trioxide is a commonly used chemical in the production of batteries, rubber, and fire retardants.

The synthetic routes for the production of antimony trioxide are many, but the most commonly used methods are the oxidation of antimony sulfide and the hydrolysis of antimony trichloride.

The oxidation of antimony sulfide is a well-established method for the production of antimony trioxide.

This process involves heating antimony sulfide with a strong oxidizing agent such as sodium peroxide or hydrogen peroxide.

The reaction results in the formation of antimony trioxide and sulfur dioxide as byproducts.

The hydrolysis of antimony trichloride is another widely used method for the production of antimony trioxide.

This process involves the reaction of antimony trichloride with water, with the addition of a catalyst such as sulfuric acid or sodium hydroxide.

The resulting reaction produces antimony trioxide and hydrochloric acid as byproducts.

Both of these synthetic routes have advantages and disadvantages.

The oxidation of antimony sulfide is relatively simple and can be performed at relatively low temperatures.

However, the production of sulfur dioxide as a byproduct can be a concern in some applications.

The hydrolysis of antimony trichloride, on the other hand, produces hydrochloric acid as a byproduct, which can be corrosive and requires careful handling.

Other synthetic routes for antimony trioxide include the reduction of antimony(V) oxide with hydrogen gas, the chlorination of sodium antimonate, and the reaction of antimony metal with oxygen.

These methods may be used in specific applications or circumstances, but they are not as widely used as the oxidation of antimony sulfide or the hydrolysis of antimony trichloride.

The production of antimony trioxide is an important part of the chemical industry, as the compound has a wide range of applications in batteries, rubber, and fire retardants.

The synthetic routes for the production of antimony trioxide vary, but the most commonly used methods involve the oxidation of antimony sulfide or the hydrolysis of antimony trichloride.

While these methods have their advantages and disadvantages, they provide a reliable and cost-effective means of producing this important chemical.