-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

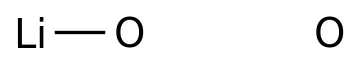

Zirconium tetrahydroxide, also known as zirconia hydroxide, is a widely used chemical in the chemical industry.

It is a white, odorless, and insoluble solid that is used in various applications, including the production of detergents, ceramics, and capacity boosters in water treatment.

The synthetic routes of zirconium tetrahydroxide include several methods, which are briefly discussed below.

- Hydrothermal Synthesis

Hydrothermal synthesis is a common method for producing zirconium tetrahydroxide.

This method involves the reaction of zirconium oxide with a concentrated hydroxide solution.

The reaction takes place in a closed autoclave at high temperatures and pressures, typically between 150-200°C and 200-300 bar.

The resulting product is a white powder that is insoluble in water.

- Pechini Process

The Pechini process is a widely used method for the synthesis of zirconium tetrahydroxide.

This process involves the reaction of zirconium oxide with an aqueous solution of sodium hydroxide.

The reaction takes place at high temperatures, typically between 120-180°C, and a pressure of approximately 20 bar.

The product is then calcined at a high temperature to remove any remaining sodium hydroxide.

- Solvothermal Synthesis

Solvothermal synthesis is another method used to produce zirconium tetrahydroxide.

This method involves the reaction of zirconium oxide with a solvent, such as ethylene glycol or diethylene glycol, and a concentrated hydroxide solution.

The reaction takes place in a high-pressure autoclave, typically at temperatures between 150-200°C and a pressure of approximately 200 bar.

The resulting product is a white powder that is insoluble in water.

- Co-Precipitation Synthesis

Co-precipitation synthesis is a method used to produce zirconium tetrahydroxide from a zirconium salt and a hydroxide source.

The reaction takes place in water, and the resulting product is a white powder that is insoluble in water.

The product is then dried, calcined, and ground to the desired particle size.

- Hydrogenation Synthesis

Hydrogenation synthesis involves the reduction of zirconium oxide with hydrogen gas to produce zirconium tetrahydroxide.

The reaction takes place in the presence of a catalyst, such as palladium on barium oxide, at a temperature of approximately 500°C.

The resulting product is a white powder that is insoluble in water.

Applications of Zirconium Tetrahydroxide

Zirconium tetrahydroxide has a wide range of applications in the chemical industry, including the following:

- Detergent Industry

Zirconium tetrahydroxide is used in the production of linear alkylbenzene sulfonates (LAS), which are used as builder materials in detergents.

The high surface area and neutralizing properties of zirconium tetrahydroxide make it an ideal catalyst for the production of LAS.

- Ceramics Industry

Zirconium tetrahydroxide is used in the production of ceramic glazes, which are applied to ceramic products to provide a glossy and hard surface.

The high surface area and low reactivity of zirconium tetrahydroxide make it an ideal catalyst for the production of ceramic glazes.

- Water Treatment

Zirconium tetrahydroxide is used as a capacity booster in