-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Zirconium is a chemical element with the symbol Zr and atomic number 40.

It is a lustrous, white, diamond-like metal that is highly resistant to corrosion and heat.

Zirconium is used in a wide range of applications due to its unique properties, including its use in the production of zirconium tetrahydroxide, which is a common source of zirconium in the chemical industry.

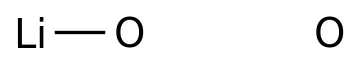

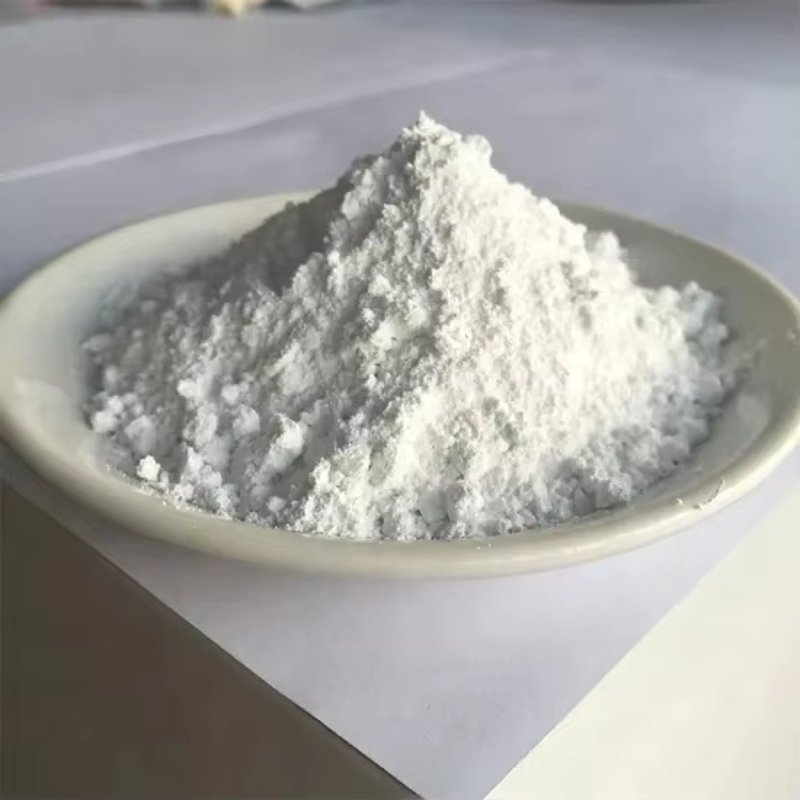

Zirconium tetrahydroxide, also known as zirconia, is a white, powdery substance that is highly prized for its use in a variety of industrial and commercial applications.

One of the main advantages of zirconium tetrahydroxide is its high melting point, which makes it suitable for use in high-temperature applications.

Additionally, zirconium tetrahydroxide is highly resistant to corrosion and is able to withstand exposure to a wide range of acids and other corrosive substances.

In the chemical industry, zirconium tetrahydroxide is used in a variety of applications, including as a catalyst in the production of various chemicals, as a purifying agent in the production of other chemicals, and as a neutralizing agent in the production of some types of adhesives and sealants.

Additionally, zirconium tetrahydroxide is used in the production of a variety of other products, including ceramics, glass, and enamel.

One of the key upstream products of zirconium tetrahydroxide is zirconium oxide, which is used in the production of the tetrahydroxide.

Zirconium oxide is typically produced by heating zirconium hydrate, which is a naturally occurring mineral, in the presence of a strong acid.

The resulting product is then purified and converted into zirconium tetrahydroxide.

Another key upstream product of zirconium tetrahydroxide is zirconium ore, which is mined from the earth and is used as the starting material in the production of zirconium oxide and other zirconium compounds.

Zirconium ore is typically found in mineral deposits, and it is extracted from the earth through a process known as mining.

The production of zirconium tetrahydroxide involves several steps, including the extraction and purification of zirconium oxide, the conversion of zirconium oxide into zirconium tetrahydroxide, and the processing and packaging of the final product.

These steps are typically carried out using a variety of specialized equipment and techniques, and they require a deep understanding of the chemical properties and behaviors of zirconium and its compounds.

In addition to its use in the production of zirconium tetrahydroxide, zirconium is also used in a variety of other applications, including in the production of nuclear reactors, in the manufacture of cutting tools, and in the production of medical implants.

Zirconium is also used in the production of a variety of other chemicals and compounds, including ceramics, glass, and enamel.

One of the key downstream products of zirconium tetrahydroxide is zirconia ceramics, which are highly valued for their ability to withstand high temperatures and their excellent mechanical properties.

Zirconia ceramics are used in a wide range of applications, including in the production of cookware, industrial machinery, and medical implants.

Another key downstream product of zirconium tetrahydroxide is glass frit, which is used in the production of a variety of types of glass, including window glass, container glass, and fiberglass.

Glass frit is a type of finely ground glass powder that is used as a precursor in the production of glass.

Zirconium tetrahydroxide is also used in the