-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The Production Process of Wollastonite (Ca(SiO3))

Wollastonite, also known as calcium silicate, is a type of mineral that is widely used in the chemical industry.

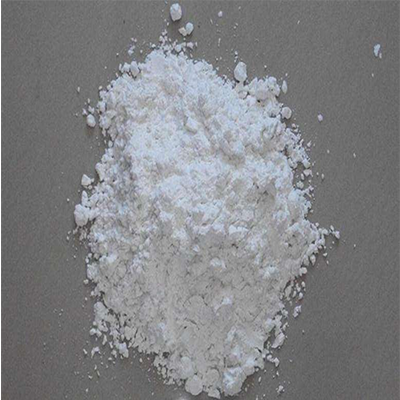

It is a white or light-colored mineral that is known for its high melting point, low water absorption, and excellent thermal insulation properties.

These properties make it an ideal material for a variety of applications, including the production of cement, ceramics, and refractories.

In this article, we will explore the production process of wollastonite, including the steps involved and the equipment used.

- Mining and crushing

The first step in the production of wollastonite is to mine the mineral from the ground.

This is typically done using heavy machinery, such as excavators and bulldozers.

Once the mineral has been extracted, it is then crushed into smaller pieces using a crusher.

The crushed mineral is then transported to the processing plant for further processing.

- Grinding and classification

Once the mineral has been crushed, it is then ground into a fine powder using a grinder.

This powder is then classified using a classification system, which separates the powder into different sizes based on their size and shape.

This is done to ensure that the powder is of a consistent size and shape, which is necessary for the next step in the process.

- Calcination

In the calcination step, the powdered mineral is heated to a high temperature in a furnace.

This process removes any impurities that may be present in the mineral, and also converts the mineral into a more stable form.

The mineral is then allowed to cool, and the resulting product is a white or light-colored powder.

- Roasting

In the roasting step, the powdered mineral is heated in a furnace to a high temperature in the presence of a gas, such as air or oxygen.

This process causes the mineral to undergo a chemical reaction, which results in the formation of wollastonite.

The mineral is then allowed to cool, and the resulting product is a white or light-colored powder.

- Grinding and packaging

Once the mineral has been processed, it is then ground into a fine powder using a grinder.

This powder is then packaged into bags or other containers for shipment.

The resulting product is a high-quality wollastonite that is suitable for a variety of applications in the chemical industry.

In conclusion, the production process of wollastonite involves several steps, including mining and crushing, grinding and classification, calcination, roasting, and packaging.

Each of these steps is carefully designed to ensure that the final product is of a high quality and meets the necessary standards for use in the chemical industry.

Whether you are interested in using wollastonite for the production of cement, ceramics, or refractories, this article has provided you with a comprehensive overview of the production process.