-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The chemical industry is a vital sector that plays a crucial role in the global economy.

It is responsible for the production of a wide range of chemical products that are used in various industries, including pharmaceuticals, textiles, electronics, and construction.

One of the key components of this industry is the production of chemical intermediates, which are used as building blocks for the manufacture of final products.

One such intermediate is 1,3,5-tris(bromomethyl)-2,4,6-trimethylbenzene, also known as BrBTB.

BrBTB is a synthetic intermediate that is used as a building block for the production of a wide range of chemical products.

It is a yellowish solid that is soluble in organic solvents and is used as a catalyst in the production of polymers and other chemical products.

The manufacturing process of BrBTB involves several steps, including the reaction of 1,3,5-trimethylbenzene with hydrogen bromide and the subsequent treatment with a base.

The resulting product is then purified and reacted with a Grignard reagent to form the final product.

The production of BrBTB is an important process in the chemical industry, and it involves several steps that must be carefully controlled to ensure the quality of the final product.

The first step in the process is the reaction of 1,3,5-trimethylbenzene with hydrogen bromide.

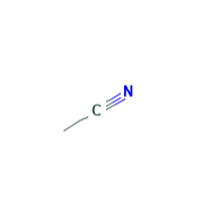

This reaction is carried out in the presence of a solvent, such as acetonitrile, and a catalyst, such as copper(II) bromide.

The reaction is exothermic, and it produces the intermediate 1,3,5-tris(bromomethyl)-2,4,6-trimethylbenzene.

The next step in the process is the treatment of the intermediate with a base, such as sodium hydroxide.

This step is necessary to neutralize the remaining bromide ions and to form the final product.

The resulting product is then purified by crystallization or by other methods, depending on the desired properties of the final product.

The final step in the process is the treatment of the purified product with a Grignard reagent, such as magnesium metal, to form the final product.

The use of BrBTB as a catalyst in the production of polymers and other chemical products has increased significantly in recent years due to its unique properties.

BrBTB is a strong Lewis acid catalyst that is able to promote the polymerization of a wide range of monomers.

This makes it a useful component in the production of polymers with specific properties, such as high molecular weight or unusual architectures.

In addition, BrBTB is able to catalyze a wide range of reactions, including the alkylation of aromatics and the polymerization of vinyl monomers.

The use of BrBTB as a catalyst in the production of polymers and other chemical products has several advantages over traditional catalysts.

For example, it is more active and more selective than other Lewis acid catalysts, such as zinc chloride.

In addition, it is more stable and less prone to deactivation than other Lewis acid catalysts.

These properties make it a valuable component in the production of chemical products and make it an important intermediate in the chemical industry.

Despite its many advantages, the production of BrBTB also presents several challenges.

One of the main challenges is the toxicity of hydrogen bromide, which is used in the production of BrBTB.

Hydrogen bromide is a highly toxic gas that can cause serious health problems, including respiratory and nervous system damage.

Therefore, the use of hydrogen bromide must be carefully controlled to ensure the safety of workers and the environment.

Another challenge in the production of BrBTB is the purity of the final product.

The purity of the final product is critical to its performance as a catalyst, and