-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Editor’s note Not long ago, the China Petroleum and Chemical Industry Federation officially released the "Petrochemical Green Process Directory (2019 Edition)", which was strictly revised after the first release of the 2018 version of the "List" to follow the advanced nature, industrialization, and promotion Re-selected processes that have significant advantages in terms of product energy consumption and material consumption, "three wastes" emissions, and process safety

.

The "Directory" has played an active role in guiding the selection of processes for enterprise investment projects, promoting the research and development and application of green processes in the industry, supporting the policy guidance of the government and financial institutions, etc.

, and has played a role in promoting the continuous improvement of the essential green level of the petrochemical industry

.

Starting today, this edition will showcase some of the newly selected green crafts for readers

.

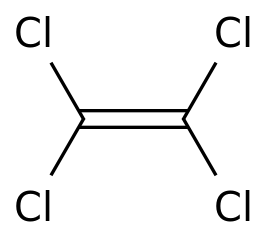

At present, the production of vinyl acetate by the calcium carbide acetylene process has been eliminated in foreign countries due to serious pollution, high energy consumption, and low purity of the products obtained

.

But in China, this polluting process still exists in some vinyl acetate production enterprises

.

The ethylene-based vinyl acetate process selected in the "Petrochemical Green Process Directory (2019 Edition)" this time is expected to change this situation

.

Recently, Celanese Asia Pacific Senior Business Director Zhao Hui said in an interview with a reporter from China Chemical Industry News that the company’s self-developed ethylene process to produce vinyl acetate overcomes the shortcomings of the technical route of calcium carbide acetylene to produce vinyl acetate, and has many environmental aspects.

Advantage

.

Ethylene replaces acetylene.

It is reported that the investment in the calcium carbide acetylene process is relatively small, but the pollution of calcium carbide slag to the environment is very serious

.

Among them, dust is an important part.

In the production of calcium carbide, the flue gas emitted by the calcium carbide furnace is the largest source of pollution

.

At the same time, calcium carbide furnace can be divided into three types: open type, internal combustion type (semi-closed type) and closed type

.

Among them, the open-type calcium carbide furnace directly emits flue gas during production, causing serious pollution, high energy consumption, and harsh operating conditions; internal combustion-type calcium carbide furnaces have high comprehensive energy consumption, and environmental pollution problems still exist, which is a process that the country restricts development

.

The ethylene process to produce vinyl acetate effectively improves the pollution problem.

.

Zhao Hui mentioned that the process route of making vinyl acetate by the ethylene method is to use glacial acetic acid, ethylene and oxygen to react at a high temperature under the action of a catalyst, and to produce vinyl acetate through multiple post-refining and purification

.

Due to the use of high-performance catalysts and the integrated utilization of energy, the ethylene-based vinyl acetate process has very low carbon dioxide emissions and few heavy component impurities

.

"The ethylene process has become the most common vinyl acetate production process in the world due to its advanced nature, high quality and environmental protection.

This process can also use other green process products as raw materials, such as biomass ethylene

.

However, China is rich in coal resources.

It has become the only country in the world that still uses the calcium carbide acetylene production process

.

The production capacity of other ethylene processes is relatively small

.

” Zhao Hui said

.

Significant environmental advantages Zhao Hui mentioned that the ethylene process to produce vinyl acetate overcomes the shortcomings of the acetylene process to produce vinyl acetate.

It has decisive advantages in environmental protection, which are mainly reflected in low energy consumption, low carbon emissions, and high product quality

.

Among them, from the perspective of process energy consumption, according to literature reports, the energy consumption of the ethylene method is lower than that of the calcium carbide acetylene method

.

The production of 1 ton of calcium carbide consumes about 3,000 kilowatt-hours of electricity, a large amount of water, and a large amount of sewage

.

However, there is no water involved in the reaction in the process of producing vinyl acetate by the ethylene method, and water is only used as a coolant, so the water consumption is very small

.

From the perspective of carbon emissions, the literature says that the calcium carbide acetylene process requires 3.

821 tons of carbon dioxide to produce 1 ton of vinyl acetate, while the ethylene process only needs to emit 2.

415 tons of carbon dioxide, which is about 58% lower than the calcium carbide acetylene process

.

From the perspective of product quality, compared to vinyl acetate produced by the calcium carbide acetylene method, the types and quantity of impurities in the products produced by the ethylene method have to be greatly reduced, which can fully meet the requirements of industry standards

.

"For downstream industries such as coatings, smoke glue, food packaging, etc.

, because their products are often in contact with the human body, they have strict requirements on the content of benzene in vinyl acetate.

.

However, based on the properties of the raw materials, benzene is more likely to be produced in vinyl acetate produced by the acetylene method, and vinyl acetate produced by the ethylene method can better meet the safety and health requirements of products in these industries

.

Zhao Hui said

.

As a chemical company with a century-old tradition of excellence, Celanese has always regarded safety and environmental protection as the cornerstones of its consistent adherence to the safety and environmental protection of a chemical company with a century-old tradition

.

Zhao Hui mentioned that since Celanese On the first day of investment and construction in China, we not only adopted the most advanced technology, but also insisted on using the highest safety and environmental protection standards to build and operate

.

The company invests a lot of manpower, financial resources and energy in technological transformation every year to ensure the process More green and environmentally friendly

.

According to him, Celanese has been improving the process of making vinyl acetate by ethylene method and is further exploring the following three aspects

.

One is to further improve the performance of the catalyst and increase the unit output rate; the other is right The comprehensive utilization of energy, consume as little energy as possible, and further reduce carbon emissions; the third is to reduce the generation of waste, make in-depth utilization of waste, and further separate its components, so as to "eat dry and squeeze" the waste

.

Ranis will also work with the Chinese government and the China Petroleum and Chemical Industry Federation to contribute to the promotion of the green development of the industry

.

"Green development and business operations are not contradictory

.

As a responsible company, we believe that only by adhering to safety and environmental protection can it be sustainable.

We will continue to integrate green sustainability into our business operations and development

.

"Zhao Hui said

.

.

The "Directory" has played an active role in guiding the selection of processes for enterprise investment projects, promoting the research and development and application of green processes in the industry, supporting the policy guidance of the government and financial institutions, etc.

, and has played a role in promoting the continuous improvement of the essential green level of the petrochemical industry

.

Starting today, this edition will showcase some of the newly selected green crafts for readers

.

At present, the production of vinyl acetate by the calcium carbide acetylene process has been eliminated in foreign countries due to serious pollution, high energy consumption, and low purity of the products obtained

.

But in China, this polluting process still exists in some vinyl acetate production enterprises

.

The ethylene-based vinyl acetate process selected in the "Petrochemical Green Process Directory (2019 Edition)" this time is expected to change this situation

.

Recently, Celanese Asia Pacific Senior Business Director Zhao Hui said in an interview with a reporter from China Chemical Industry News that the company’s self-developed ethylene process to produce vinyl acetate overcomes the shortcomings of the technical route of calcium carbide acetylene to produce vinyl acetate, and has many environmental aspects.

Advantage

.

Ethylene replaces acetylene.

It is reported that the investment in the calcium carbide acetylene process is relatively small, but the pollution of calcium carbide slag to the environment is very serious

.

Among them, dust is an important part.

In the production of calcium carbide, the flue gas emitted by the calcium carbide furnace is the largest source of pollution

.

At the same time, calcium carbide furnace can be divided into three types: open type, internal combustion type (semi-closed type) and closed type

.

Among them, the open-type calcium carbide furnace directly emits flue gas during production, causing serious pollution, high energy consumption, and harsh operating conditions; internal combustion-type calcium carbide furnaces have high comprehensive energy consumption, and environmental pollution problems still exist, which is a process that the country restricts development

.

The ethylene process to produce vinyl acetate effectively improves the pollution problem.

.

Zhao Hui mentioned that the process route of making vinyl acetate by the ethylene method is to use glacial acetic acid, ethylene and oxygen to react at a high temperature under the action of a catalyst, and to produce vinyl acetate through multiple post-refining and purification

.

Due to the use of high-performance catalysts and the integrated utilization of energy, the ethylene-based vinyl acetate process has very low carbon dioxide emissions and few heavy component impurities

.

"The ethylene process has become the most common vinyl acetate production process in the world due to its advanced nature, high quality and environmental protection.

This process can also use other green process products as raw materials, such as biomass ethylene

.

However, China is rich in coal resources.

It has become the only country in the world that still uses the calcium carbide acetylene production process

.

The production capacity of other ethylene processes is relatively small

.

” Zhao Hui said

.

Significant environmental advantages Zhao Hui mentioned that the ethylene process to produce vinyl acetate overcomes the shortcomings of the acetylene process to produce vinyl acetate.

It has decisive advantages in environmental protection, which are mainly reflected in low energy consumption, low carbon emissions, and high product quality

.

Among them, from the perspective of process energy consumption, according to literature reports, the energy consumption of the ethylene method is lower than that of the calcium carbide acetylene method

.

The production of 1 ton of calcium carbide consumes about 3,000 kilowatt-hours of electricity, a large amount of water, and a large amount of sewage

.

However, there is no water involved in the reaction in the process of producing vinyl acetate by the ethylene method, and water is only used as a coolant, so the water consumption is very small

.

From the perspective of carbon emissions, the literature says that the calcium carbide acetylene process requires 3.

821 tons of carbon dioxide to produce 1 ton of vinyl acetate, while the ethylene process only needs to emit 2.

415 tons of carbon dioxide, which is about 58% lower than the calcium carbide acetylene process

.

From the perspective of product quality, compared to vinyl acetate produced by the calcium carbide acetylene method, the types and quantity of impurities in the products produced by the ethylene method have to be greatly reduced, which can fully meet the requirements of industry standards

.

"For downstream industries such as coatings, smoke glue, food packaging, etc.

, because their products are often in contact with the human body, they have strict requirements on the content of benzene in vinyl acetate.

.

However, based on the properties of the raw materials, benzene is more likely to be produced in vinyl acetate produced by the acetylene method, and vinyl acetate produced by the ethylene method can better meet the safety and health requirements of products in these industries

.

Zhao Hui said

.

As a chemical company with a century-old tradition of excellence, Celanese has always regarded safety and environmental protection as the cornerstones of its consistent adherence to the safety and environmental protection of a chemical company with a century-old tradition

.

Zhao Hui mentioned that since Celanese On the first day of investment and construction in China, we not only adopted the most advanced technology, but also insisted on using the highest safety and environmental protection standards to build and operate

.

The company invests a lot of manpower, financial resources and energy in technological transformation every year to ensure the process More green and environmentally friendly

.

According to him, Celanese has been improving the process of making vinyl acetate by ethylene method and is further exploring the following three aspects

.

One is to further improve the performance of the catalyst and increase the unit output rate; the other is right The comprehensive utilization of energy, consume as little energy as possible, and further reduce carbon emissions; the third is to reduce the generation of waste, make in-depth utilization of waste, and further separate its components, so as to "eat dry and squeeze" the waste

.

Ranis will also work with the Chinese government and the China Petroleum and Chemical Industry Federation to contribute to the promotion of the green development of the industry

.

"Green development and business operations are not contradictory

.

As a responsible company, we believe that only by adhering to safety and environmental protection can it be sustainable.

We will continue to integrate green sustainability into our business operations and development

.

"Zhao Hui said

.