-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

1, the status quo at present, China's trace element supply model is still inorganic trace elements mainly, mainly because of its cheap and long-term use and thus formed an inherent habit. However, China's feed-grade inorganic trace elements come from the by-products of industry, because of low prices, upstream enterprises do not do adequate treatment, easy to residual a large number of toxic and harmful substances, which brings a lot of problems to feed security and stability. These problems with the use of organic trace elements only slightly alleviated, mainly due to increased competition in domestic feed enterprises, the demand for feed quality further improved, coupled with the demand for animal apparent characteristics of breeding terminals. In the past two years, in the group feed enterprises, led by organic trace elements have gradually been recognized and widely used. In this environment, new problems arise, and how to evaluate organic trace elements scientifically and apply rationally has brought new problems to many feed formulators.h85

under the pressure of the above-mentioned dual problems, more and more feed enterprises have chosen to put trace element premix directly out, similar to the composite multi-dimensional model, to professional trace element production and processing enterprises, focus their energy to their best part. Feed has seven or eight kinds of trace elements, dozens of inorganic and organic monomer raw materials, feed enterprises if one by one assessment, will inevitably increase a large number of human and financial input, not to assess, will increase the risk of the security and stability of feed.h85custom composite mines are not the most effective and secure solution. For different needs of different customers, the use of customized way, all trace elements premix to professional suppliers to do. The benefits of custom composite mines can be summed up simply as follows: (1) reducing the risk of corporate procurement, which used to be more than a dozen, and now only needs to purchase one or more compound mines. (2) reduce the pressure of storage and warehouse, before dozens of micro-monomers, the need for classification of storage, not only occupy raw materials warehouse, but also inorganic mine long-term storage is prone to oxidative discoloration, block moisture absorption phenomenon. To use a composite mine instead, you can remove such problems. (3) reduce the quality control personnel and equipment a lot of investment.h85

, how to produce high-quality trace element premix, I personally think it is necessary to do a good job in the following aspects of raw material control, formula control, production process and equipment and quality control.h85

2, the control of raw materials for trace element premix raw materials is mainly to grasp the three principles, namely: the control of oxidation factors, the control of block factors and the control of health indicators.h85

2.1

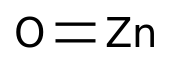

oxidizing factor control is well known, trace element premix is most likely to produce color change is iron elements, the raw material light green divalent iron ions are oxidized into yellow trivalent iron ions, resulting in premix discoloration. So, what causes the oxidation of iron ions, and how do we control this color change factor? A brief summary of three aspects. First, the control of oxidants in feed. As mentioned above, most of the trace elements of feed grade in China come from industrial by-products. The production of feed-grade zinc sulfate is mostly made by wet method, the raw material used is from the industry's secondary zinc oxide, because zinc oxide contains other elements such as cadmium, lead, arsenic, iron and so on. Therefore, in order to obtain a high content of zinc sulfate products, it is necessary to remove the miscellaneous, in addition to the process of oxidants in the important position. And these anti-hybrid oxidants are mostly hydrogen peroxide, there will be a part of the zinc sulfate raw materials into the trace element premix, so the trace element premix of the diceroine iron oxidation into trivalent iron. Second, the choice of carrier, many enterprises use stone powder as a trace element premix carrier, due to stone powder led to premix pH

increase, divalent iron in pH 5

will be oxidized into trivalent iron ions. Third, the selected organic iron is not sufficiently chelated, in the premix of free water, a large number of oxidation into trivalent iron. The solution to the above problems is very simple, first, to detect the amount of oxidant residues in each batch of raw materials. Second, choose the appropriate trace element carrier. Third, scientific and effective assessment of organic trace elements.h85

2.2

the control of premix ingenuation factor is mainly caused by the moisture-absorbing moisture and recrystallization of the raw material, the main reason for this phenomenon is due to the residual of a large number of free water, free acids and chlorides in the raw material. The main methods of controlling the clumps are, first, strictly formulate enterprise standards, because the relevant national standard control indicators of trace element monomer are less, can not rely on national standards alone to select a high-quality raw materials, enterprises in accordance with their own needs and testing strength to develop detailed enterprise internal control standards. Second, strictly control all raw materials in the above three than the enterprise internal control standards. Third, to minimize the use of five water copper sulfate.h85

control of 2.3

of health indicators on top of national standards, which require additional control of nickel and mercury levels, as nickel directly affects skin coloring in young animals and poultry, with the highest nickel content in copper sulfate. Mercury is highly susceptible to damage to the gastric mucous membranes and intestinal fluff, resulting in a decrease in digestion and absorption rate, so weaning pig food needs to focus on controlling whether the mercury is above standard. Another important problem is the control of dioxins, China's feed-grade copper sulfate production of raw materials more use of the production of circuit board waste erosion liquid. The waste corrosion liquid of the production circuit board has just three conditions for producing dioxins, namely, benzene, chloride ions and high temperature. Therefore, we tested the content of dioxins in finished feed grade copper sulfate, which exceeded the EU standard

3 to 5 times. As we all know, dioxins are high carcinogens, milk pig feed in the long-term use of high copper is bound to bring harm to the environment and the human body.h85

3, formula control due to the low absorption rate of inorganic trace elements, coupled with low prices, accounting for very little cost of feed, so the production enterprises have been more than NRC and national standard 3

times or even higher proportion in the use of inorganic trace elements. As we all know, the use of trace elements is a certain safety threshold, and there is a certain proportion of elements in absorption. Due to our large proportion of the use, animals can not fully absorb, resulting in a great waste of trace elements, while a large number of cations on the animal intestinal electrolyte balance also caused a certain degree of stimulation. Therefore, the use of trace elements, we should focus on grasping the effective content and the proportion between elements of the two basic principles, to the ideal trace element model to design different varieties, different stages of animal trace elementpreding. h85

in the design of trace element premixes in any animal, the formulation design principles must also be taken into account in the following factors: First, the loss caused by the redox reaction between different forms of trace elements. Second, the best ratio of addition between the four elements of iron, copper, zinc and manganese. Third, the proportion of organic trace elements and inorganic trace elements. Fourth, whether different regions are in the area of trace element deficiency. Fifth, in different seasons, trace elements need to increase the amount of safety. Among them, the proportion of inorganic trace elements and organic trace elements is the most confusing problem encountered by many feed enterprises in the design process. Here our production company has the basic database of trace element application and the market application experience value is even more important. h85

4, production process, equipment and quality control 4.1

production process first, we must be clear the characteristics of high-quality trace element premix, summarized in five points. That is: first, so that the microcomposition can be evenly distributed. Second, improve the instability of trace components. Third, so that the level of added can be standardized. Fourth, reduce the production process of feed enterprises. Fifth, maximize the synergy of micro-components. h85 more than

visible, evenly distributed in the first place, then how to make the weight of different, different moisture, particle size of different chemicals can be mixed evenly, no doubt, two aspects, namely: ultra-micro-smashing of extremely small component sage raw materials, automatic pre-mixing equipment scientific applications. h85 according to the Poisson distribution principle, requires mixed uniformity (CV) of less than 3% of premix products, each sample at least 900

of the group to prevent the group in nutrient supply and analysis of errors. Such as trace element premix Central Asian sodium selenium, calcium iodide, organic chromium these products add very low levels, and the effective dose and poisoning dose close. Therefore, ultra-micro-smashing is necessary to make the mix even. At present, enterprises are using dry ball grinding way to crush. The average particle size after crushing is between 500 and 600

. h85

4.2

the scientific use of automatic pre-mixing equipment production equipment, greatly improve production efficiency and reduce the cost of raw materials procurement for feed enterprises. The safety and stability of trace element premixes is also strictly controlled. The control system controls the feeding order of raw materials in the formula to reduce the problem of multi-throwing and leakage due to artificial feeding. Accurate microweighing can effectively control the material input error. The double blade mixer ensures that the uniformity of material mixing is controlled at less than 3% in

. h85

4.3

precision quality control and visual traceability, while having a scientific process and sophisticated fully automatic premixing equipment, must also have a sophisticated quality control process and traceability system. First of all, the determination of mixing uniformity, the traditional determination of the uniformity of the mixing of trace elementpredes is to detect the iron elements, however, the detection of iron elements there are two problems, first, iron elements accounted for a large proportion of micro-mines, can not fully reflect the mixing uniformity of the multi-mine. Second, there are currently some enterprises formulated in the micro-mine does not contain iron elements, so it is not possible to detect iron elements to reflect the mixing of the product uniformity. Micro-components such as iodine selenium cobalt can be selected to judge the mixing uniformity index, so more accurate. h85

the current use of trace element premixes, the more important aspect is to place the feed enterprise's trust in the selected multi-mine supplier brand. And as a multi-mine producer itself, we must develop a detailed traceability system, so that multi-mine is not a cold productplaced in the customer's warehouse, must let the head of the feed enterprise can really perceive the product from raw material procurement, formula design, pre-mixing processing, finished product testing, logistics and other aspects of the real situation. To this end, some enterprises in the market have also launched a product online traceability query system, so that customers can clearly understand the products they use. h85 .