Sticky wall problem is the main problem hindering the operation of spray dryer

-

Last Update: 2020-05-28

-

Source: Internet

-

Author: User

Search more information of high quality chemicals, good prices and reliable suppliers, visit

www.echemi.com

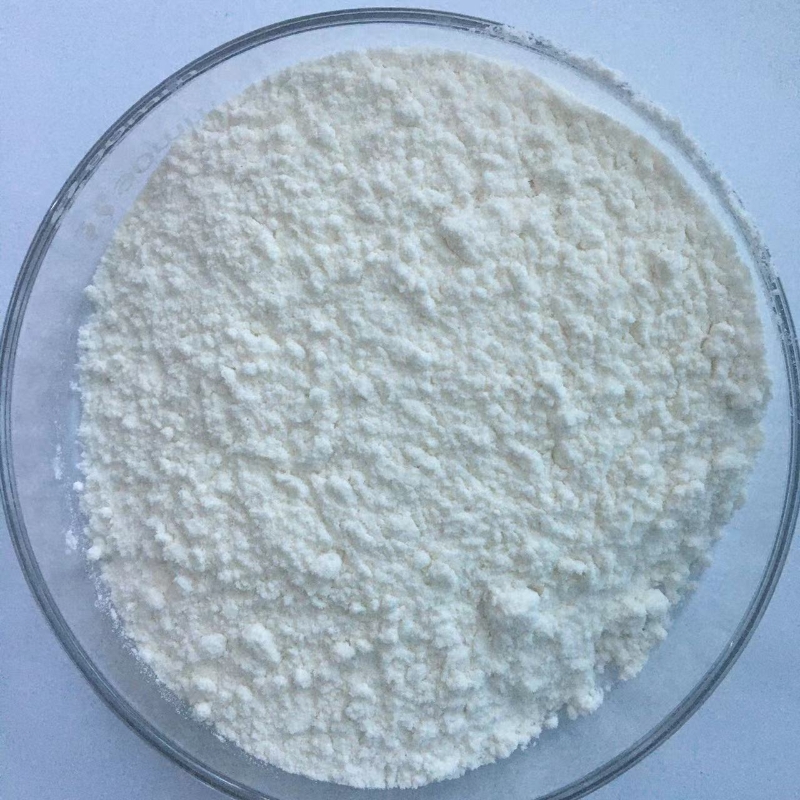

spray drying is a widely used process of zui in the liquid process forming and drying industry, which is suitable for the generation of powdery, granular or blocky solid products from solutions, lotions, suspended lotions and pumpable paste liquid raw materialsTherefore, spray drying is an ideal process when the particle size distribution, residual moisture content, accumulation density and new particle installation of the finished product must meet the criteria of jinguse this drying method, spray dryer gas solid two-phase contact surface area is large, drying time is short, generally 5 to 30s, suitable for drying thermally sensitive materialsDrying products have good performance, can get 30 to 50 mm particles, product mobility and quick-activityThe disadvantage is that the dryer is large in volume and low in heat transfer coefficient, resulting in low thermal efficiency and large power consumptionspray dryer classification methods are many, according to the flow of gas can be divided into and flow, reverse flow and mixed flow, according to the installation of the atomizer can be divided into the upper spray type, down-spray type, according to the structure of the atomizer can be divided into centrifugal, pressure and airflow, according to whether the heating gas cycle can be divided into open, partial circulation and closedsticky wall phenomenon is a prominent problem hindering the normal operation of spray dryer, especially the spray drying process of solid preparations (especially Chinese medicine)Material sticky wall is not only not conducive to operation collection, but also over time, sensitive sticky wall material will deteriorate into non-conforming materialFrom a process point of view, the solution includes the selection of suitable solvents, the addition of auxiliary materials, change the process parameters, but these methods can not be adjustable, so it is necessary to seek a fundamental solution from the point of view of the equipmentThe researchers studied the problem of sticky walls and clumps in the drying process, and concluded that the main cause of sticky walls was wall temperatureSpray dryer stickwall generally has the following three conditions:1, semi-wet material stickwall: the reason is that the spray of fog droplets before the surface drying has been in contact with the wall, so sticking to the wall, the position of the stickwall is generally on the surface of the fog drop trajectory of the nebulizer, and the structure of the nebulizer, hot air in the tower movement state; Wall: the reason is that the material at a certain temperature to reach the melting point began to dissolve and stick, adhere to the wall of the device,3, dry powder surface adhesion: dry powder in the limited space of movement there will always be some encountering wall, which can not be avoided, but such a stickwall is generally not thick, as long as through air blowing or gently knock can shock down, zui simple solution is the inner wall polishing, can solve the problem to a certain extentcommon methods to prevent sticky walls are as follows:1, using the clampwall drying tower, during which air cooling, so that the wall temperature remains below 50 degrees C; The wall is equipped with a row of nozzles composed of air brooms, and make it slowly rotate along the wall of the tower, 4, tower wall increase air hammer, through the hammer knock, forced to break out of the sticky wall material, 5, increase the processing accuracy of the equipment, the wall polishing of the tower can also reduce the sticking wall

This article is an English version of an article which is originally in the Chinese language on echemi.com and is provided for information purposes only.

This website makes no representation or warranty of any kind, either expressed or implied, as to the accuracy, completeness ownership or reliability of

the article or any translations thereof. If you have any concerns or complaints relating to the article, please send an email, providing a detailed

description of the concern or complaint, to

service@echemi.com. A staff member will contact you within 5 working days. Once verified, infringing content

will be removed immediately.