-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

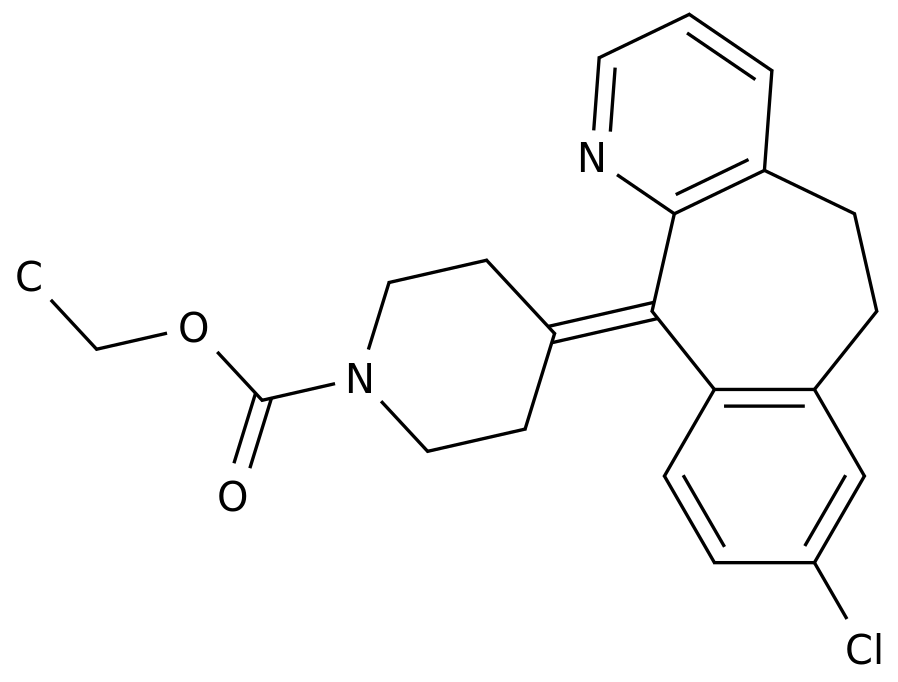

Azelastine hydrochloride is an antihistamine drug that is commonly used to treat allergy symptoms such as sneezing, itching, and watery eyes.

It is also sometimes used to treat nasal congestion and hives.

This article will provide information on the instruction of azelastine hydrochloride in the chemical industry.

Azelastine hydrochloride is a synthetic drug that is derived from the naturally occurring compound, castarolen.

It is produced through a series of chemical reactions that involve the conversion of castarolen into azelastine hydrochloride.

The manufacturing process for azelastine hydrochloride involves several steps, including the synthesis of the starting material, the reaction of the starting material with hydrochloric acid, and the purification of the resulting product.

The first step in the manufacturing process for azelastine hydrochloride is the synthesis of the starting material, which is castor oil.

Castor oil is extracted from the seeds of the castor oil plant, which is native to the tropical regions of the Americas.

The synthesis of castor oil involves the hydrogenation of ricinoleic acid, which is the major component of castor oil.

This process involves the addition of hydrogen atoms to the ricinoleic acid molecule, which results in the formation of castor oil.

The next step in the manufacturing process for azelastine hydrochloride is the reaction of the castor oil with hydrochloric acid.

This reaction involves the esterification of the castor oil with hydrochloric acid, which results in the formation of azelastine hydrochloride.

The reaction is carried out in the presence of a solvent, such as water or ethanol, and a catalyst, such as sulfuric acid or pyridine.

The reaction is typically carried out at a temperature of between 50-60 degrees Celsius.

After the reaction is complete, the resulting product is purified to remove any unwanted impurities.

This purification process typically involves the use of chromatography, which separates the pure azelastine hydrochloride from any impurities that may be present.

The resulting product is then dried and processed into a form that is suitable for use as a pharmaceutical ingredient.

The instruction of azelastine hydrochloride in the chemical industry is a complex process that requires a high level of expertise and knowledge.

The process involves several steps, including the synthesis of the starting material, the reaction of the starting material with hydrochloric acid, and the purification of the resulting product.

The manufacturing process for azelastine hydrochloride must be carefully controlled and monitored to ensure that the final product meets the required specifications for purity and efficacy.

In conclusion, azelastine hydrochloride is an important antihistamine drug that is commonly used to treat allergy symptoms.

The manufacturing process for azelastine hydrochloride involves several steps, including the synthesis of the starting material, the reaction of the starting material with hydrochloric acid, and the purification of the resulting product.

The instruction of azelastine hydrochloride in the chemical industry requires a high level of expertise and knowledge, and must be carefully controlled and monitored to ensure that the final product meets the required specifications for purity and efficacy.