-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

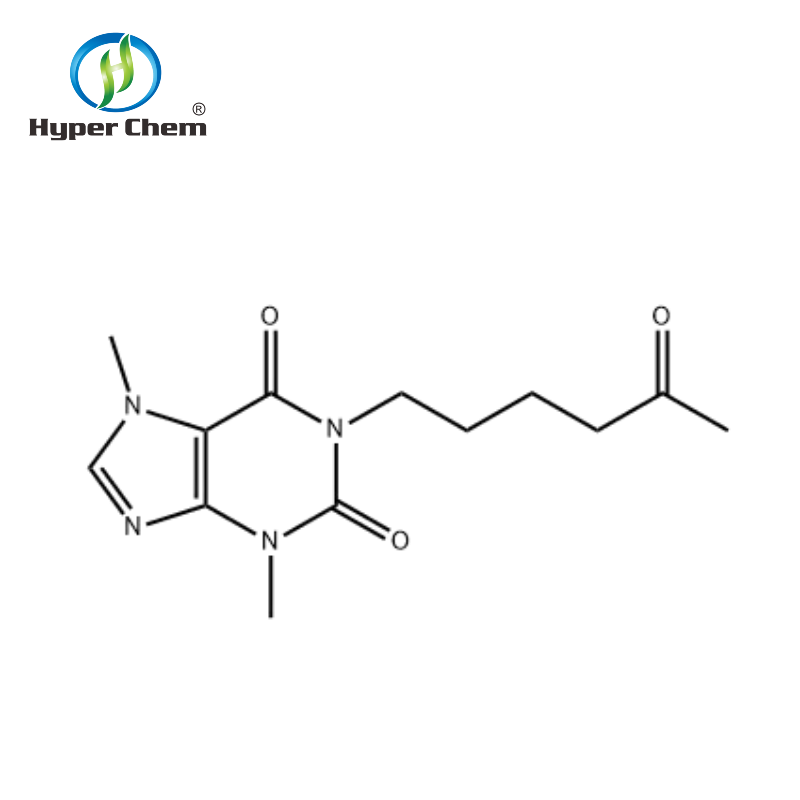

Cinepazide, also known as Methyl Salicylate, is a chemical compound that is commonly used in the production of a wide range of products in the chemical industry.

It is a white, crystalline solid that has a characteristic wintergreen-like odor and a sweet, fruity taste.

Cinepazide is primarily used as a flavoring agent in the production of food and beverages, as well as in various pharmaceutical products.

It is also a versatile chemical that can be used in a variety of other applications, including the production of perfumes and fragrances, cosmetics, and personal care products.

The production of Cinepazide involves several steps, including extraction, purification, and refining of the raw materials, as well as the synthesis of the compound itself.

The process typically begins with the extraction of wintergreen oil from the leaves of wintergreen plants, which are native to North America.

The oil is extracted through a process known as steam distillation, in which the leaves are steamed to release the oil.

Once the oil has been extracted, it is purified through a process known as molecular distillation, which involves the use of centrifugal forces to separate the oil into its various components.

The purified oil is then subjected to a process known as fractional distillation, in which the oil is heated and the various components are separated based on their boiling points.

The next step in the production of Cinepazide is the synthesis of the compound itself.

This is typically accomplished through a process known as alkylation, in which the raw material is treated with a specific type of alkylating agent.

The resulting product is then purified and refined through a series of chemical reactions, until it is ready for use in various industrial applications.

One of the most critical factors in the production of Cinepazide is the quality of the raw materials used in the process.

The wintergreen oil used in the extraction process must be of the highest quality in order to ensure that the final product will meet the required specifications.

This requires careful selection and testing of the raw materials, as well as strict quality control measures throughout the production process.

Another important aspect of the production of Cinepazide is the efficiency of the production process.

This is important for several reasons, including the cost of the raw materials and the energy used in the production process, as well as the environmental impact of the process.

As such, the production of Cinepazide must be optimized in order to minimize waste and maximize efficiency.

The production of Cinepazide is a complex process that requires a high degree of technical expertise and specialized equipment.

As such, it is typically carried out by large chemical manufacturing companies that have the resources and capabilities to produce the compound in large quantities.

In conclusion, the production of Cinepazide is a critical component of the chemical industry, as it is used in a wide range of products and applications.

The process involves several steps, including the extraction and purification of raw materials, as well as the synthesis and refining of the compound itself.

The production of Cinepazide must be carried out with the highest levels of quality control and efficiency in order to ensure that the final product meets the required specifications and is produced in a sustainable and environmentally responsible manner.