-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

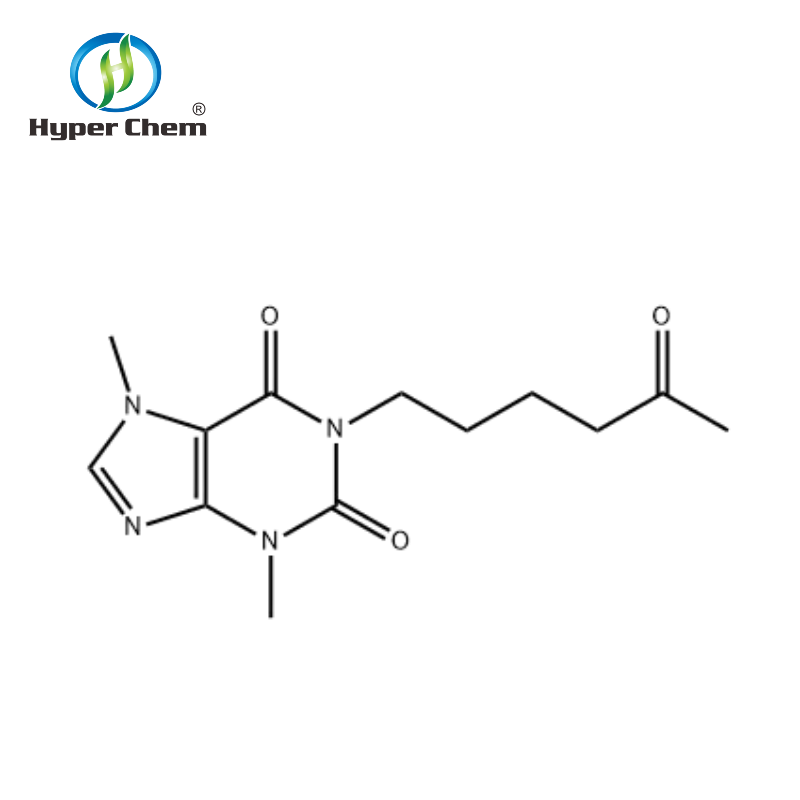

Nitrendipine is a calcium channel blocker drug that is used in the treatment of hypertension, angina pectoris, and other cardiovascular diseases.

The chemical industry plays a crucial role in the production of nitrendipine, and it involves a series of complex chemical reactions that require strict attention to detail and adherence to safety protocols.

In this article, we will discuss the instruction of nitrendipine in the chemical industry, including the chemical reactions involved in its production, the safety measures that must be taken, and the quality control procedures that are used to ensure the purity and efficacy of the final product.

Chemical Reactions Involved in the Production of Nitrendipine

Nitrendipine is synthesized through a series of chemical reactions that involve several intermediate compounds.

The initial step in the synthesis of nitrendipine involves the reaction of diethyl amidorexidation with 2-chloromethyl-4,5,6,7-tetrahydrobenzimidazole (CMT) to form the compound 1-(4,5,6,7-tetrahydro-2-oxo-1,2,3,4-tetrahydrobenzimidazol-2-yl)-N,N-diethylcarbamate.

This compound is then exposed to a series of chemical reactions such as hydrolysis and alkylation to form the final product, nitrendipine.

Safety Measures in the Production of Nitrendipine

The production of nitrendipine requires strict adherence to safety protocols to prevent accidents and minimize the risk of exposure to toxic chemicals.

The safety measures that are typically followed in the production of nitrendipine include:

- Personal protective equipment (PPE): All employees involved in the production of nitrendipine must wear appropriate PPE such as gloves, safety glasses, and lab coats to protect themselves from exposure to toxic chemicals.

- Hazardous chemical handling: All hazardous chemicals used in the production of nitrendipine must be handled with care and stored in appropriate containers to prevent leaks and spills.

- Emergency response plan: An emergency response plan must be in place to ensure that employees know what to do in case of an emergency such as a chemical spill or fire.

- Quality control procedures: Strict quality control procedures must be followed to ensure that the final product is pure and effective.

This involves testing the product at various stages of production to ensure that it meets the required standards.

Quality Control Procedures in the Production of Nitrendipine

Quality control is a critical aspect of the production of nitrendipine, and it involves several steps to ensure the purity and efficacy of the final product.

The quality control procedures that are typically followed in the production of nitrendipine include:

- Raw material testing: Raw materials used in the production of nitrendipine must be tested to ensure that they meet the required standards and are free from contaminants.

- In-process testing: Samples of the product are taken at various stages of production and tested to ensure that the product meets the required standards.

- Final product testing: The final product is tested to ensure that it meets the required standards for purity, potency, and stability.

Conclusion

The production of nitrendipine involves a series of complex chemical reactions that require strict attention to detail and adherence to safety protocols.

The chemical industry plays a crucial role in the production of nitrendipine, and it is essential to follow safety measures and quality control procedures to ensure the safety of employees and the quality of the final product.

Chemical engineers and technicians must have a thorough understanding of the chemical reactions involved in the production of nitrendipine and the safety measures that must be taken to prevent accidents and minimize the risk of exposure to toxic chemicals.

By following these protocols, the production of nitrendip