-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

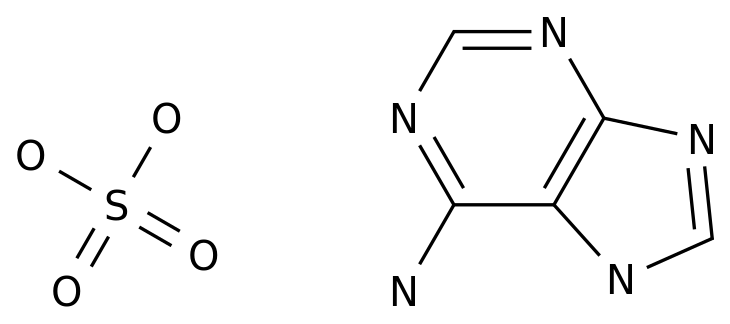

The 1H-1,2,3-Triazole is a versatile and important molecule with diverse applications in various fields, including pharmaceuticals, agrochemicals, and materials science.

The production process of 1H-1,2,3-Triazole involves several steps, which are primarily chemical reactions that transform simple starting materials into the desired product.

In this article, we will discuss the various steps involved in the production process of 1H-1,2,3-Triazole in the chemical industry.

Step 1: Preparation of Benzotriazole

The production process of 1H-1,2,3-Triazole starts with the preparation of benzotriazole, which is a key intermediate.

Benzotriazole is synthesized by reacting benzene with hydrazine in the presence of a solvent such as water or ethanol.

The reaction involves the following steps:

Benzene + Hydrazine -> Benzotriazole

Step 2: Paper Chromatography

The reaction mixture obtained from the previous step contains a mixture of products, including benzotriazole.

To purify the benzotriazole, the mixture is subjected to paper chromatography, a separation technique that uses a paper sheet coated with a stationary phase.

The mixture is applied on the paper sheet, and the different components migrate at different rates due to their differences in polarity and adsorption properties.

The benzotriazole band is then scraped off the paper sheet and recrystallized to obtain pure benzotriazole.

Step 3: Hydrogenation

The next step in the production process of 1H-1,2,3-Triazole is the hydrogenation of benzotriazole.

Hydrogenation is a chemical reaction where hydrogen gas is added to a molecule to reduce the functionality of the molecule.

In this case, the benzotriazole is hydrogenated to convert it into 1H-1,2,3-Triazole.

The hydrogenation reaction is typically carried out in the presence of a metal catalyst such as palladium or platinum.

Step 4: Recrystallization

After the hydrogenation step, the product is recrystallized to obtain pure 1H-1,2,3-Triazole.

Recrystallization is a technique used to purify solids by dissolving them in a suitable solvent and then allowing the solvent to slowly evaporate, leaving behind pure crystals.

Step 5: characterization

The final step in the production process of 1H-1,2,3-Triazole is the characterization of the product.

This involves various techniques such as spectroscopy, melting point determination, and thermogravimetric analysis to determine the chemical structure, physical properties, and stability of the produced 1H-1,2,3-Triazole.

In conclusion, the production process of 1H-1,2,3-Triazole involves several steps, including the preparation of benzotriazole, paper chromatography, hydrogenation, recrystallization, and characterization.

These steps require the use of various chemicals, solvents, and equipment, and the entire process must be carried out under carefully controlled conditions to ensure the purity and stability of the final product.

The 1H-1,2,3-Triazole is an important molecule with diverse applications in various fields, and its production requires a high degree of chemistry expertise and technology.