-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

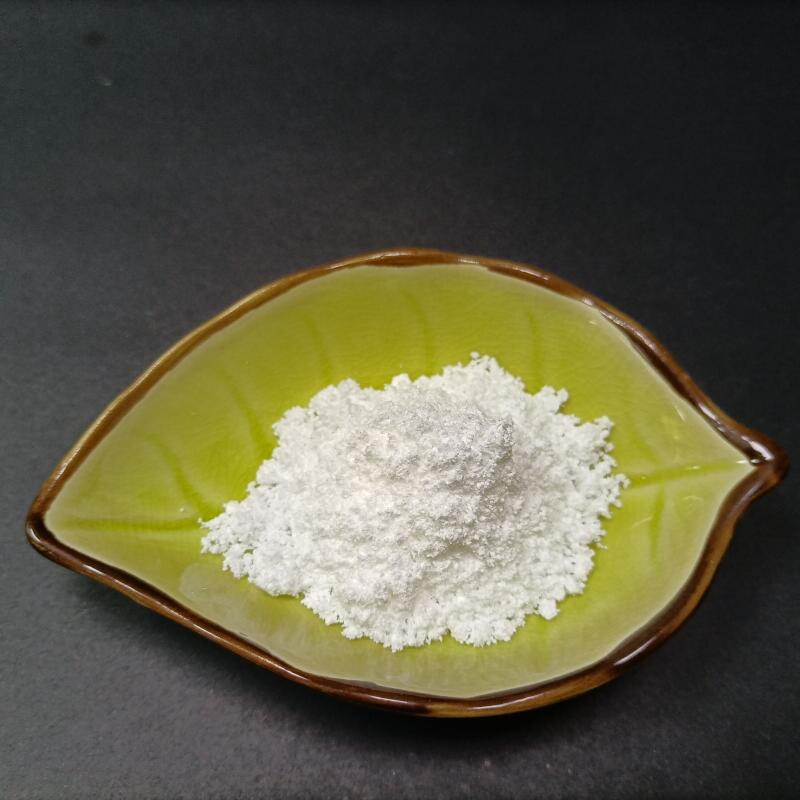

2,4-Hexadienoic acid is a versatile intermediate chemical that is widely used in the production of a variety of chemicals, plastics, and other products.

The production process for 2,4-hexadienoic acid involves several steps, each of which requires careful control to ensure the quality and purity of the final product.

The first step in the production of 2,4-hexadienoic acid is the synthesis of cyclohexene, which is a raw material for the production of the acid.

Cyclohexene is typically produced by the catalytic cracking of naphtha, which is a fraction of crude oil.

The cyclohexene is then converted into 2,4-hexadienal through a process known as hydroformylation.

This process involves the use of a metal catalyst, such as rhodium or iridium, and high pressure carbon monoxide gas to convert the cyclohexene into 2,4-hexadienal.

The next step in the production of 2,4-hexadienoic acid is the reduction of 2,4-hexadienal to 2,4-hexadienoic acid.

This is typically done using a reducing agent such as hydrogen gas in the presence of a metal catalyst, such as palladium or platinum.

The use of the reducing agent causes the removal of the double bond in the 2,4-hexadienal molecule, resulting in the formation of 2,4-hexadienoic acid.

Once the 2,4-hexadienoic acid has been produced, it is typically purified and isolated from any impurities that may have been present in the initial reaction mixture.

This purification process typically involves the use of various chemical and physical separation techniques, such as distillation or crystallization.

The final step in the production of 2,4-hexadienoic acid is the packaging and shipment of the product.

This typically involves the use of various packaging materials, such as drums or bottles, and the transportation of the product to the customer or final user.

In conclusion, the production process for 2,4-hexadienoic acid is a complex and multi-step process that requires careful control and attention to detail at each step.

The production of high-quality 2,4-hexadienoic acid requires the use of advanced catalysts, separation techniques, and other equipment and technology, making the production of this important chemical a challenging but rewarding process.