-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

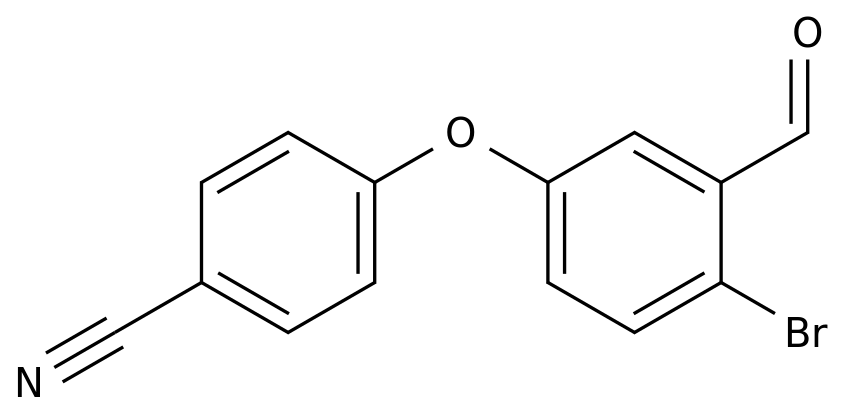

The Production Process of 2-Bromo-5-hydroxybenzaldehyde in the Chemical Industry: An In-Depth Analysis

2-Bromo-5-hydroxybenzaldehyde, commonly referred to as Bromo-5-hydroxybenzaldehyde or 2,5-Dibromo-3-hydroxybenzaldehyde, is a highly valuable organic compound with diverse applications in the chemical industry.

It is widely used as a building block for the synthesis of various dyes, medicines, fragrances, and other chemical products.

The production process of 2-Bromo-5-hydroxybenzaldehyde involves several steps, including the synthesis of its precursors, the reaction conditions, and the product isolation and purification.

Synthesis of Precursors

The synthesis of 2-Bromo-5-hydroxybenzaldehyde typically begins with the production of its precursors, which are 2-bromo-5-nitrobenzene and 3,5-diiodo-2-methoxybenzene.

These precursors are synthesized through a series of chemical reactions that involve the use of various reagents, catalysts, and solvents.

Reaction Conditions

Once the precursors have been synthesized, they are mixed together in appropriate ratios to facilitate the reaction.

The reaction conditions, such as the temperature, pressure, and reaction time, play a crucial role in the efficiency and yield of the synthesis process.

The selection of the reaction conditions depends on the specific reaction conditions and the properties of the reactants.

Isolation and Purification of Product

After the reaction is complete, the resulting mixture is typically filtered and washed with a solvent to remove any impurities.

The resulting product is then purified through a series of procedures such as recrystallization, chromatography, and distillation to remove any remaining impurities and to obtain a pure sample of 2-Bromo-5-hydroxybenzaldehyde.

Challenges in Production

Despite its wide applications and the significant economic benefits it offers, the production of 2-Bromo-5-hydroxybenzaldehyde can be challenging due to several factors.

One of the primary challenges is the high cost of raw materials, which can make the production process uneconomical.

Additionally, the reaction conditions can be sensitive and difficult to control, leading to variable yields and product quality.

The purification process can also be time-consuming and costly, requiring the use of specialized equipment and solvents.

Conclusion

The production process of 2-Bromo-5-hydroxybenzaldehyde involves several steps, including the synthesis of its precursors, the reaction conditions, and the product isolation and purification.

Despite the challenges associated with its production, 2-Bromo-5-hydroxybenzaldehyde is a highly valuable compound with diverse applications in the chemical industry.

Its widespread use as a building block for the synthesis of various chemicals demonstrates the significance of this compound in the chemical industry.

As the industry continues to evolve, the production process of 2-Bromo-5-hydroxybenzaldehyde is likely to become more efficient, cost-effective, and environmentally sustainable.