-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The production process of 3-bromo-4-methylbenzenesulphonamide involves several steps, from the preparation of the starting materials to the final product.

This article will provide an overview of the production process, including the necessary equipment and the key steps involved.

Preparation of the Starting Materials

The production of 3-bromo-4-methylbenzenesulphonamide begins with the preparation of the starting materials.

The key starting material is 4-methylbenzenesulphonyl chloride, which is synthesized by the reaction of 4-methylbenzaldehyde with sulphuryl chloride in the presence of a Lewis acid catalyst, such as aluminum chloride.

The reaction is exothermic, and the resulting product is recrystallized from a polar solvent, such as water or methanol, to obtain pure 4-methylbenzenesulphonyl chloride.

Synthesis of 3-Bromo-4-methylbenzenesulphonamide

The next step in the production of 3-bromo-4-methylbenzenesulphonamide is the synthesis of the title compound.

This is achieved by treating 4-methylbenzenesulphonyl chloride with sodium hydroxide in water, followed by the addition of a solution of bromine in a polar solvent, such as methanol or ethanol.

The reaction is exothermic, and the resulting product is extracted with a water-immiscible solvent, such as ether or benzene, to remove the excess bromine and sodium hydroxide.

The organic layer is then dried over anhydrous sodium sulfate and filtered, and the solvent is removed under reduced pressure to obtain the crude product.

Purification of the Product

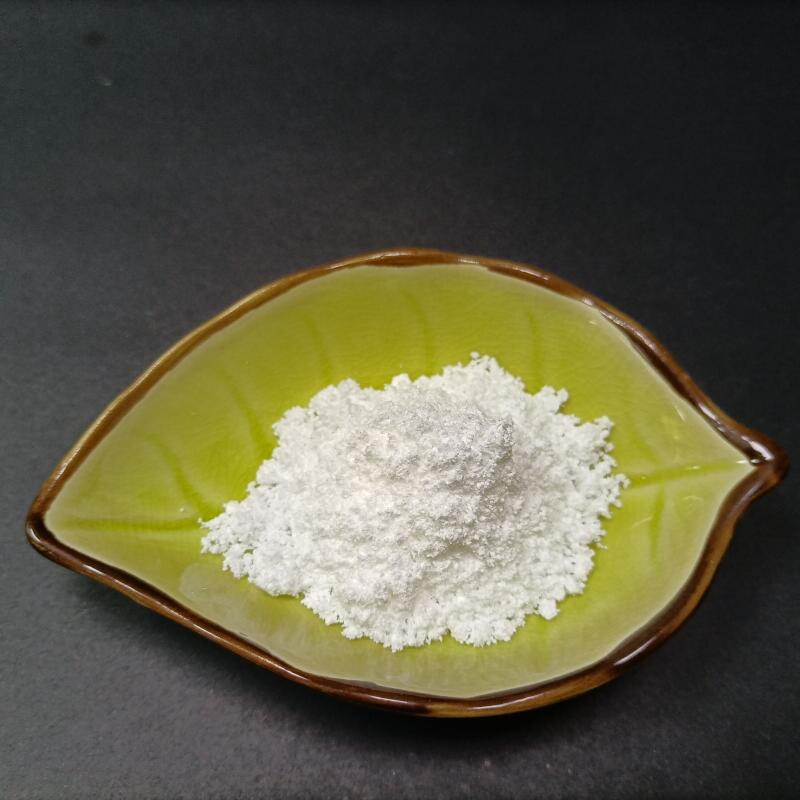

The crude product obtained from the previous step is impure and requires further purification to obtain pure 3-bromo-4-methylbenzenesulphonamide.

This is achieved by flash chromatography using a polar stationary phase, such as silica gel or alumina.

The eluent used is a mixture of a polar solvent, such as methanol or ethanol, and a non-polar solvent, such as ethyl acetate or hexane.

The optimal conditions, such as the solvent composition and the flow rate, must be optimized to ensure complete separation of the desired product from any impurities.

The final step in the production process is the characterization of the obtained 3-bromo-4-methylbenzenesulphonamide.

This is achieved by using standard spectroscopic techniques, such as infrared spectroscopy (IR), nuclear magnetic resonance spectroscopy (NMR), and mass spectrometry (MS), to determine the molecular structure of the product.

Additionally, the melting point and the solubility of the product in different solvents can also be determined to confirm the purity and identity of the product.

Equipment and Resources Required

The production of 3-bromo-4-methylbenzenesulphonamide requires a range of equipment and resources.

The following are some of the essential pieces of equipment and resources required:

- Chemical reagents and solvents: Sulphuryl chloride, 4-methylbenzaldehyde, aluminum chloride, sodium hydroxide, bromine, water, methanol, ethanol, ether, benzene, silica gel, alumina, methanol, ethanol, ethyl acetate, hexane, infrared spectrophotometer, nuclear magnetic resonance spectrometer, mass spectrometer, melting point apparatus, and solubility tester.

- Laboratory equipment: A