-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

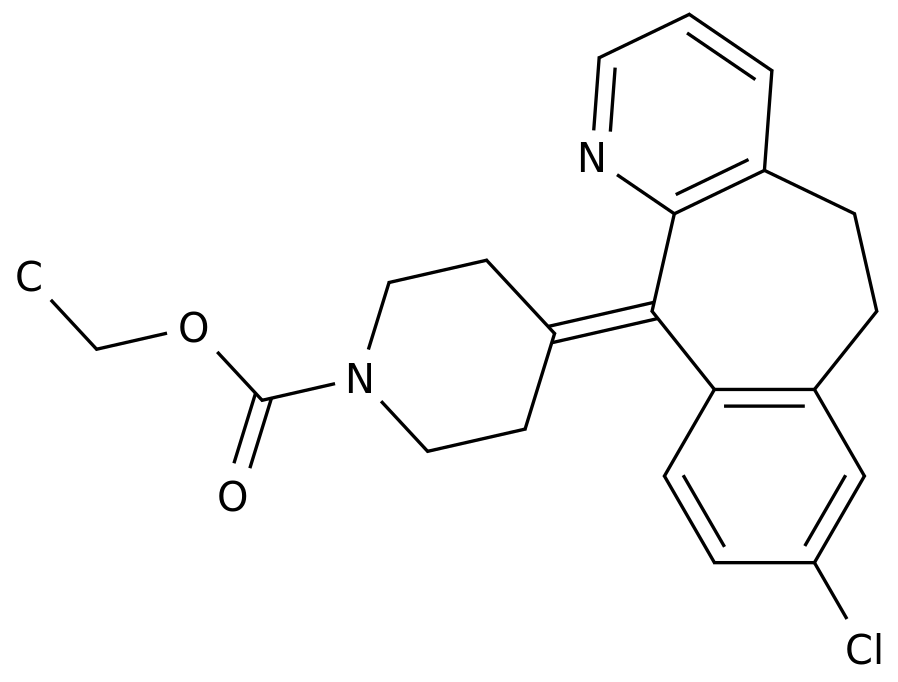

Azelastine hydrochloride is an antihistamine drug that is commonly used to treat allergy symptoms such as sneezing, itching, and watery eyes.

The production process of azelastine hydrochloride involves several steps, from the synthesis of the starting materials to the final formulation of the drug.

- Synthesis of starting materials

The synthesis of azelastine hydrochloride starts with the production of the starting materials required for the synthesis process.

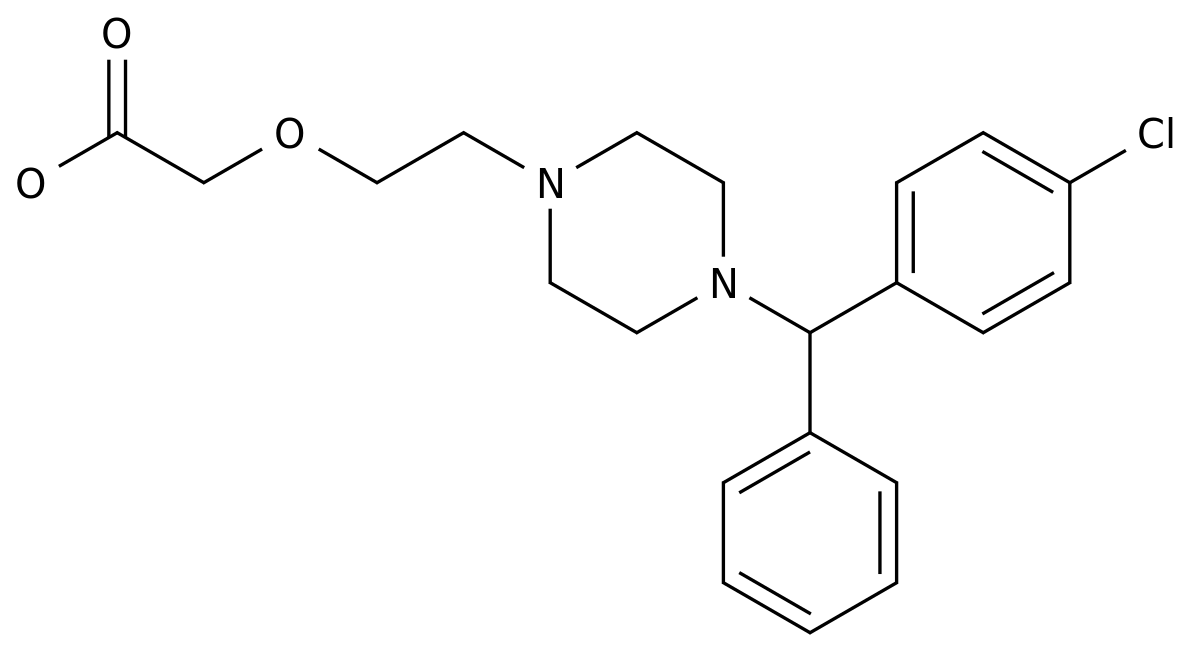

The key starting material for the synthesis of azelastine hydrochloride is benzaldehyde, which is derived from benzoic acid through a series of chemical reactions.

Other starting materials used in the synthesis process include hydrochloric acid, sodium hydroxide, and various organic compounds.

- Condensation reactions

The next step in the production process of azelastine hydrochloride is the condensation reaction.

In this step, the starting materials are reacted with each other in the presence of a condensing agent, such as sodium hydroxide, to form a new compound.

The reaction is carried out in several stages, with the intermediate products being treated with additional condensing agents to form the final product.

- Purification and isolation

After the condensation reaction, the resulting compound is purified and isolated.

This involves the use of various chemical techniques, such as crystallization and chromatography, to separate the desired compound from any impurities that may be present.

- Formulation

The final step in the production process of azelastine hydrochloride is the formulation of the drug.

This involves mixing the pure compound with other ingredients to create a stable and effective form of the drug.

The formulation process includes the addition of excipients, such as binders and fillers, to improve the consistency and stability of the drug.

- Quality control

Throughout the production process, quality control checks are carried out to ensure that the final product meets the required standards for purity, potency, and efficacy.

These checks include chemical and physical tests, such as spectroscopy and chromatography, to verify the identity and composition of the drug.

In conclusion, the production process of azelastine hydrochloride involves several steps, from the synthesis of starting materials to the final formulation of the drug.

The process requires the use of various chemical reactions, purification techniques, and quality control measures to ensure the production of a safe and effective drug.