-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

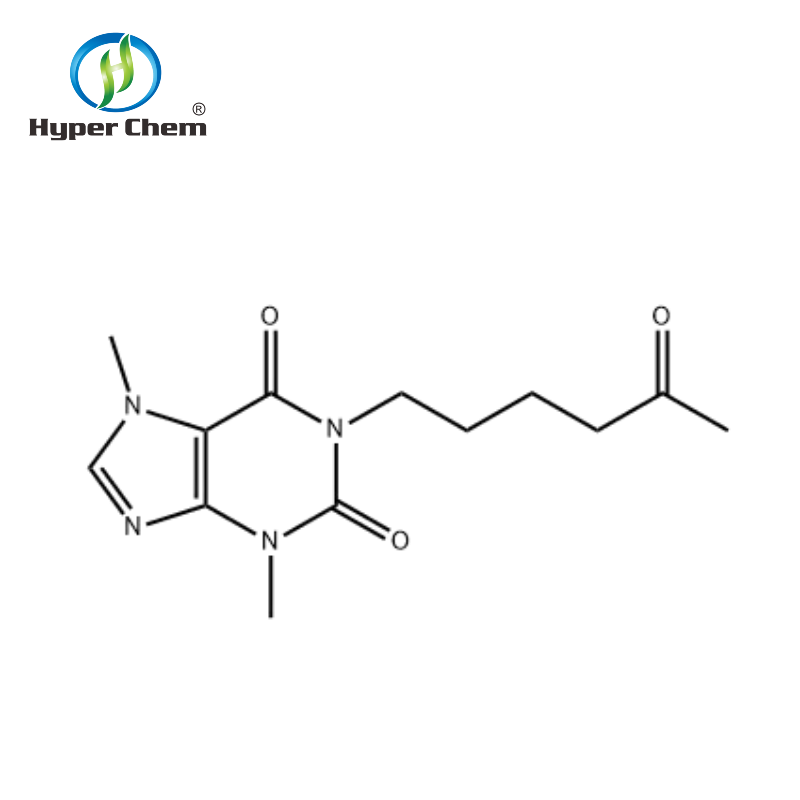

Cinepazide is a commonly used chemical in the chemical industry, primarily used in the production of various types of plastics and synthetic fibers.

The production process of Cinepazide involves several steps, each of which requires careful attention to detail and a thorough understanding of the underlying chemistry.

Step 1: Preparation of the Reactants

The first step in the production process of Cinepazide is the preparation of the reactants.

The reactants used in the production of Cinepazide are ethylene and benzaldehyde, which are first purified to remove any impurities and then mixed in the appropriate ratios.

Step 2: Addition of Catalyst

The next step is the addition of a catalyst to the reactants.

The catalyst used in the production of Cinepazide is typically a type of metal oxide, such as aluminum oxide or titanium dioxide.

The catalyst helps to speed up the reaction between the reactants, allowing the reaction to proceed more quickly and efficiently.

Step 3: Heating

The reactants and catalyst are then heated to a high temperature in the presence of a solvent, such as benzene or toluene.

The high temperature causes the reactants to react with one another, resulting in the formation of Cinepazide.

Step 4: Cooling and Purification

After the reaction is complete, the mixture is cooled to room temperature and then purified to remove any remaining impurities.

This step is critical, as the purity of the final product is important for its end use.

Step 5: Distillation

The purified mixture is then distilled to separate the Cinepazide from the solvent.

This step involves heating the mixture to a high temperature and then cooling it again, causing the Cinepazide to evaporate and separate from the solvent.

Step 6: Crystallization

The final step in the production process of Cinepazide is crystallization.

The Cinepazide is allowed to cool and then formed into crystals, which are collected and dried.

The crystals are then ground into a fine powder, which is the final product.

Challenges in Production

While the production process of Cinepazide appears relatively straightforward, there are several challenges that must be overcome in order to produce high-quality product.

One of the primary challenges is the purity of the reactants, as even small amounts of impurities can affect the quality of the final product.

Another challenge is the selection of the appropriate solvent for the purification step, as different solvents can lead to different purity levels in the final product.

Finally, the control of the reaction temperature and time is critical, as too much or too little time can result in lower quality product.

Conclusion

Cinepazide is an important chemical in the production of various types of plastics and synthetic fibers.

The production process involves several steps, including the preparation of the reactants, addition of a catalyst, heating, cooling and purification, distillation and crystallization.

Each step must be carefully controlled and monitored in order to produce a high-quality final product.

Despite the challenges, the production process of Cinepazide is a well-established and reliable process, and Cinepazide is widely used in the chemical industry.