-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

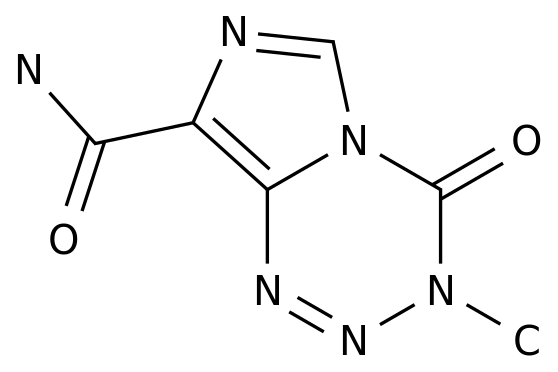

Etoposide is a chemotherapy drug that is commonly used to treat a variety of different types of cancer, including testicular cancer, small cell lung cancer, and sarcomas.

The production process for etoposide involves a number of different steps, each of which is carefully controlled and monitored to ensure that the final product is safe and effective.

The first step in the production process for etoposide is the synthesis of the active ingredient.

This is typically done through a series of chemical reactions that involve the use of various reagents and catalysts.

The reaction conditions, including temperature, pressure, and reaction time, must be carefully controlled to ensure that the reaction proceeds smoothly and efficiently.

Once the active ingredient has been synthesized, it is typically purified through a series of chromatography steps.

This involves passing the mixture of chemicals through a column that contains a stationary phase, such as silica gel or alumina.

The chemicals in the mixture interact with the stationary phase in different ways, causing them to separate out and allowing the pure active ingredient to be collected and isolated.

After the active ingredient has been purified, it is typically formulated into a final product.

This typically involves mixing the active ingredient with other chemicals, such as excipients and preservatives, to create a stable and effective form of the drug.

The formulation process must be carefully controlled to ensure that the final product is safe and effective, and that it meets all relevant regulatory standards.

Once the final product has been formulated, it is typically packaged into individual doses or units.

This typically involves filling the doses or units with the appropriate amount of the drug, and sealing them to protect the contents from moisture and other environmental factors.

The packaging process must be carefully controlled to ensure that the final product is safe and effective, and that it meets all relevant regulatory standards.

Overall, the production process for etoposide is a complex and multifaceted process that requires careful control and monitoring at every step.

By following established protocols and guidelines, it is possible to produce a safe and effective chemotherapy drug that can help to improve the lives of cancer patients.