-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Felodipine is a calcium channel blocker drug that is primarily used to treat hypertension, angina pectoris, and certain types of heart rhythm disorders.

The production process of felodipine involves several steps, which will be discussed in detail in this article.

Step 1: Extraction and Isolation of the Active Ingredient

The active ingredient in felodipine is extracted from the seed of the plant known as Nerium oleander.

The seeds are collected and cleaned, and then the extraction process begins.

There are several methods that can be used to extract the active ingredient, including solvent extraction and steam distillation.

Once the active ingredient has been extracted, it is further purified to remove any impurities.

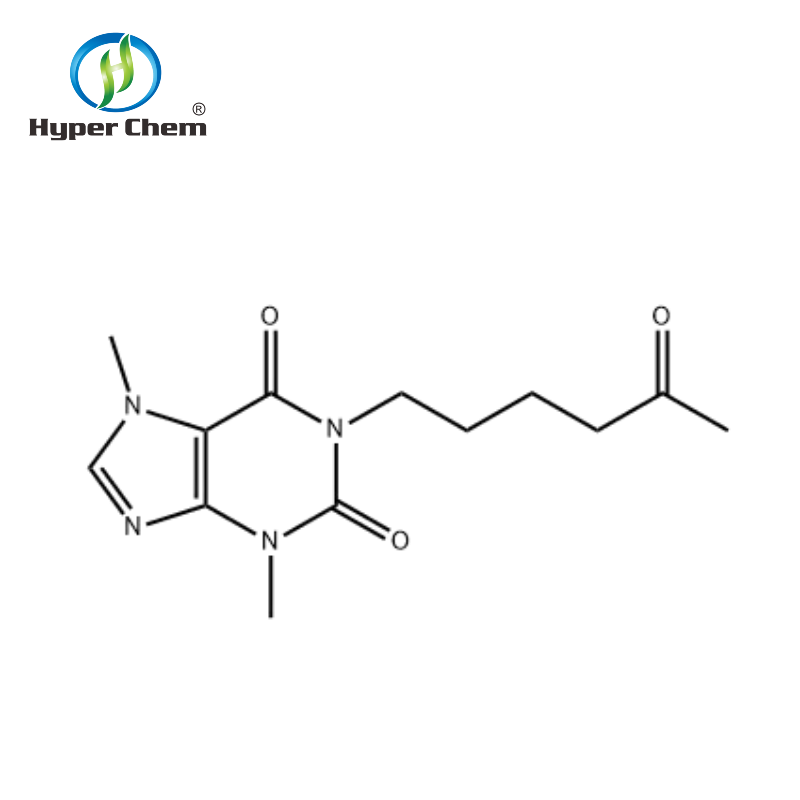

Step 2: Chemical Synthesis of the Active Ingredient

While the active ingredient in felodipine can be extracted from the Nerium oleander plant, it is also possible to synthesize it chemically.

This involves a series of chemical reactions in which the various components of the drug are combined to create the final product.

The manufacturing process for felodipine typically involves several steps, including the synthesis of the active ingredient, the formation of the final mixture, and the encapsulation of the drug in a shell.

Step 3: Formulation of the Drug

Once the active ingredient has been synthesized or extracted, it is mixed with other ingredients to create the final mixture.

This mixture is then encapsulated in a shell made of a material that will dissolve in the body and release the drug over time.

The composition of the final mixture and the type of shell used will depend on a variety of factors, including the intended use of the drug, the patient's medical history, and the patient's individual needs.

Step 4: Quality Control

Throughout the production process, quality control measures are in place to ensure that the final product meets all necessary standards.

This includes testing the drug for purity, potency, and stability.

The manufacturing process must also adhere to strict guidelines and regulations set forth by the regulatory agencies in the region where the drug will be sold.

Step 5: Packaging and Distribution

Once the drug has been produced and quality controlled, it is packaged in appropriate dosages and distributed to pharmacies and other healthcare providers.

The packaging must be designed to protect the drug from moisture, light, and other environmental factors that could compromise its effectiveness.

The Production Process of Felodipine

The production process of felodipine involves several steps, including the extraction and isolation of the active ingredient, the chemical synthesis of the active ingredient, the formulation of the drug, quality control measures, and packaging and distribution.

The final product is a highly effective hypertension and heart condition drug that is widely used in various countries around the world.