-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Flunixin meglumine, also known as flunixin meglumine salt, is a nonsteroidal anti-inflammatory drug (NSAID) that is commonly used in veterinary medicine to treat a variety of conditions, including pain, fever, and inflammation.

The production process for flunixin meglumine involves several steps, including the synthesis of the active ingredient, formulation, and packaging.

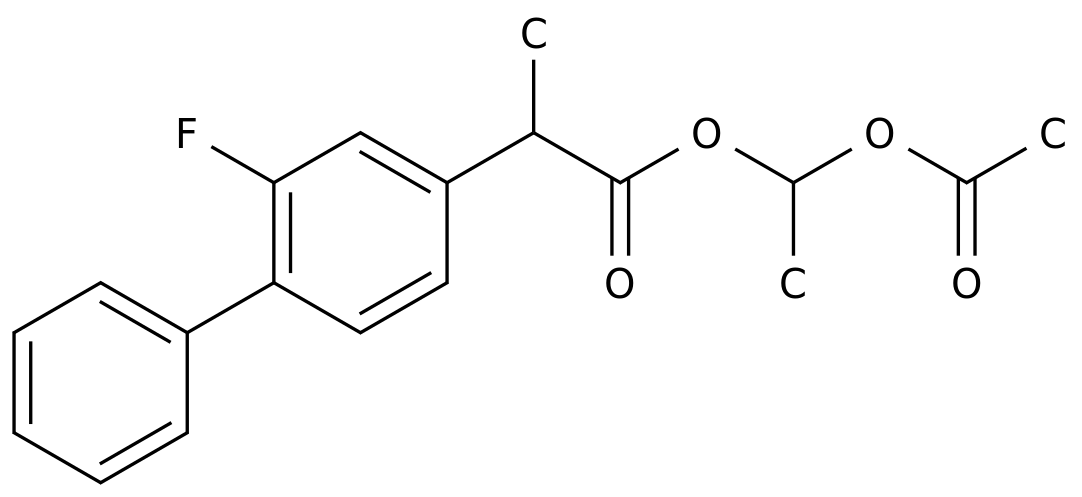

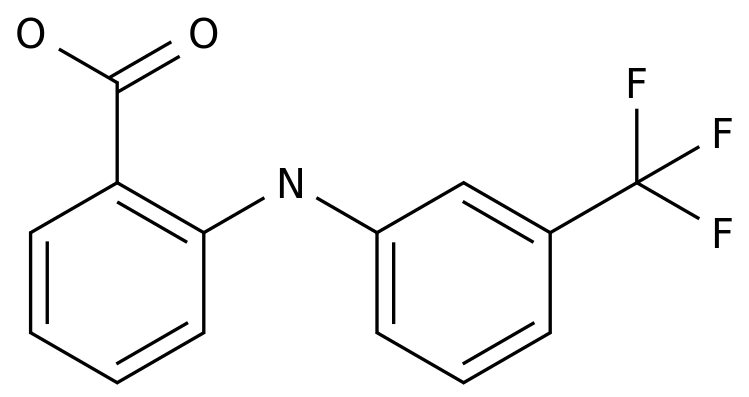

The synthesis of flunixin meglumine begins with the production of the active ingredient, which is known as flunixin.

Flunixin is synthesized through a series of chemical reactions that involve the reaction of several different chemical compounds.

The synthesis process involves several steps, including the preparation of the starting materials, the reaction of the materials in the presence of a catalyst, and the purification of the resulting product.

Once the flunixin has been synthesized, it is then combined with meglumine, a compound that is used as a excipient.

This process is known as salt formation and it is a way to produce a stable and water soluble compound.

The resulting product is a white to off-white crystalline powder that is known as flunixin meglumine.

After the synthesis and formulation of the active ingredient, the next step in the production process is the formulation of the final product.

This involves mixing the active ingredient with other ingredients such as fillers, binders, and preservatives to create a stable and effective formulation.

The formulation process also includes the addition of a solvent to create a solution or suspension that can be easily administered to the patient.

Once the formulation has been created, the final step in the production process is the packaging of the final product.

The packaging process involves the use of containers that are specifically designed to protect the product from light, air, and moisture.

The containers are also labeled with information about the product, including the active ingredient, the dosage, and any warnings or precautions that should be taken when using the product.

It is important to note that the production process of Flunixin meglumine must be carried out in a controlled environment, such as a laboratory or a pharmaceutical manufacturing facility.

This is to ensure that the product is produced in a consistent and safe manner, and to prevent any contamination or degradation of the active ingredient.

Additionally, the production process must also comply with all relevant regulations and guidelines for the production of veterinary medications.

In conclusion, the production process of Flunixin meglumine involves several steps, including the synthesis of the active ingredient, formulation, and packaging.

The process is carried out in a controlled environment, and must comply with all relevant regulations and guidelines for the production of veterinary medications.

The end product is a stable and effective formulation of the active ingredient that can be used to treat a variety of conditions in animals.