-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

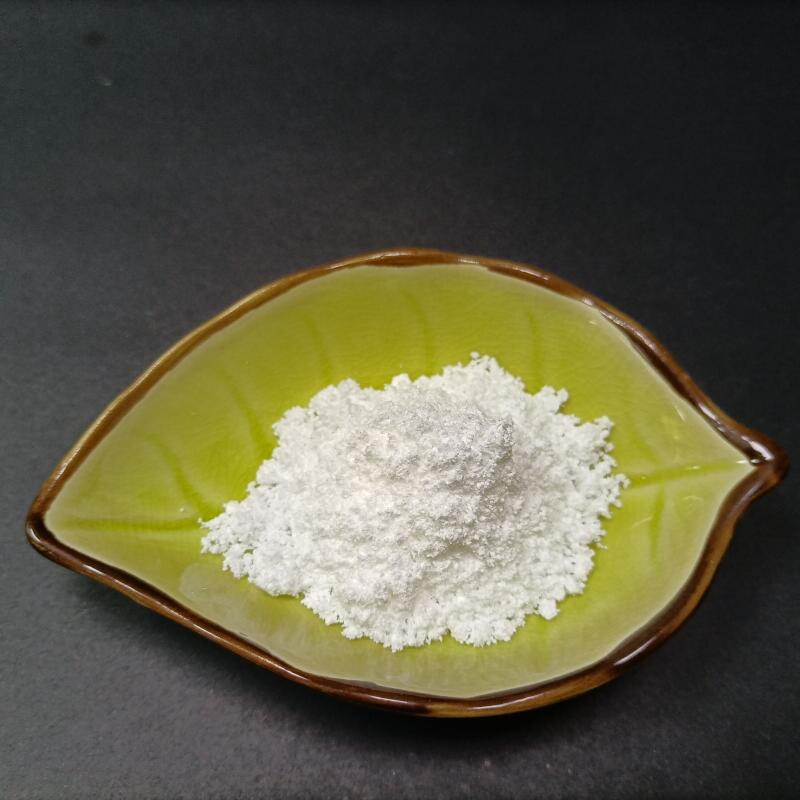

Indinavir sulfate is a medication used to treat HIV infection.

It is a protease inhibitor that works by blocking the action of the enzyme protease, which is essential for the production of infectious viral particles.

The production process of indinavir sulfate involves several steps, including synthesis, purification, and formulation.

Synthesis:

The synthesis of indinavir sulfate involves several steps, including the synthesis of the parent compound, indinavir.

Indinavir is synthesized by reacting a substituted benzaldehyde with a substituted phenyl acetate in the presence of a Lewis acid catalyst.

The reaction product is then treated with aqueous sodium hydroxide, which leads to the formation of the corresponding phenylamine.

This compound is then cyclized to form the indole ring, which is then nitrated to form indinavir nitrate.

Finally, the nitrate is converted to the sulfate by treatment with sulfuric acid.

Purification:

After synthesis, the indinavir sulfate is purified through several chromatography steps.

The first step involves gel permeation chromatography (GPC), which separates the impurities based on their size.

The next step involves high-performance liquid chromatography (HPLC), which separates the impurities based on their chemical properties.

Finally, the purified indinavir sulfate is dried and sieved to remove any remaining impurities.

Formulation:

The final step in the production process of indinavir sulfate is formulation.

This involves mixing the purified indinavir sulfate with other excipients, such as lactose, to form a stable and palatable formulation.

The formulation is then filled into capsules or tablets and packaged for distribution.

Quality Control:

The production process of indinavir sulfate is closely monitored to ensure that the final product meets the required quality standards.

This includes testing for impurities, stability, and efficacy.

The product is also tested for its shelf life, which is the period during which the product remains stable and retains its pharmaceutical properties.

Advantages and Limitations:

The production process of indinavir sulfate is complex and involves several steps, each of which must be carefully controlled to ensure the quality of the final product.

However, the use of advanced technologies and purification methods has made it possible to produce high-quality indinavir sulfate at a lower cost.

The use of this drug has been associated with several advantages, including improved survival rates in HIV-infected patients.

Conclusion:

The production process of indinavir sulfate involves several steps, including synthesis, purification, and formulation.

The drug is used to treat HIV infection and is an essential component of HIV treatment regimens.

The production process of indinavir sulfate is closely monitored to ensure that the final product meets the required quality standards.

The use of advanced technologies and purification methods has made it possible to produce high-quality indinavir sulfate at a lower cost.