-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

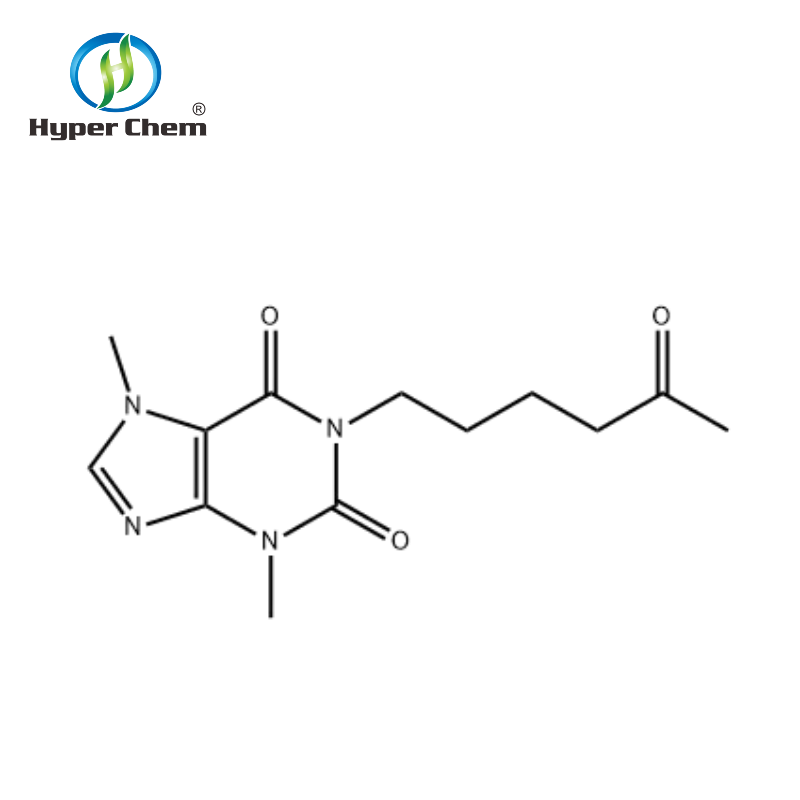

Manidipine dihydrochloride is a pharmaceutical drug that is used to treat various medical conditions.

It is an important molecule in the chemical industry and is widely used for the treatment of cardiovascular diseases, hypertension, and other conditions.

The production process of Manidipine dihydrochloride involves several steps, which are essential to obtain the final product.

Step 1: Extraction of Raw Materials

The production of Manidipine dihydrochloride begins with the extraction of raw materials such as progesterone and chloroform.

These raw materials are sourced from natural resources such as plants or synthesized in a laboratory setting.

The extraction process involves the use of solvents such as water, ethanol, or other organic compounds to isolate the desired molecules.

Step 2: Purification of Raw Materials

After the extraction of raw materials, they are purified to remove any impurities or unwanted compounds.

This step is essential to ensure the quality of the final product.

Purification techniques such as crystallization, filtration, and chromatography are used to separate the pure compounds from the impurities.

Step 3: Synthesis of Manidipine dihydrochloride

Once the pure raw materials are obtained, they are subjected to a series of chemical reactions to synthesize Manidipine dihydrochloride.

This involves the use of reagents, catalysts, and high temperatures and pressures.

The synthesis process takes place in a laboratory setting, and the reaction conditions are closely monitored to ensure the safety and efficiency of the process.

Step 4: Purification of the Synthesized Product

After the synthesis of Manidipine dihydrochloride, the resulting product is purified to remove any impurities or unwanted byproducts.

This step involves the use of purification techniques such as recrystallization, chromatography, and precipitation.

The purified product is then dried and ground into a fine powder.

Step 5: Compression of the Powder

The purified Manidipine dihydrochloride powder is then compressed into tablets or capsules.

This step involves the use of tableting machines, which compress the powder into the desired shape.

The tablets or capsules are then coated with a layer of gelatin or other materials to protect the active ingredient from degradation.

Step 6: Quality Control

The final step in the production process of Manidipine dihydrochloride is quality control.

This involves the testing of the final product to ensure that it meets the required specifications for purity, potency, and efficacy.

The product is tested for physical characteristics such as size, shape, and color, as well as for chemical characteristics such as molecular weight and impurity levels.

Conclusion

The production process of Manidipine dihydrochloride involves several steps that are essential to obtain the final product.

From the extraction of raw materials to the synthesis, purification, compression, and quality control, each step is critical to ensuring the quality and efficacy of the final product.

With careful monitoring and control of the production process, Manidipine dihydrochloride can be produced in a safe and efficient manner, providing patients with access to an important pharmaceutical drug for the treatment of various medical conditions.